Sand is “the world’s second largest natural resource after water”. It is not only found on beaches and in deserts, but also in the construction industry, manufacturing and scientific research. But are you confused – some “sand” can be used as a concrete material and some “sand” can only be used as a landscape filler. The key to the problem lies in the two key indicators of sand density and particle size.

This article will introduce you to the types of sand, density, size, application range, to help you understand how density and particle size affect the performance of sand. At the same time recommend the applicable machinery and equipment to provide you with practical processing guidelines.

I. Types of Sand

Some sand is naturally occurring and some is made by human processing. The following are the common types:

1.River sand: formed by long-term washing of running water, with rounded particles and low content of clay and impurities. It is the preferred type of sand in the construction industry and is commonly used in reinforced concrete structures.

2.Beach sand: produced in the beach or offshore area, the particles are fine but the salt content is very high. It needs to be desalinated before it can be used for construction.

3.Desert sand: occurs in the desert area. Due to its fine grain and smooth surface, it cannot be bonded with cement to form a stable concrete structure. It can be used for artistic creation and landscape filling.

4.Quartz Sand: The main component is silicon dioxide (SiO₂). This kind of sand has uniform density and very few impurities, which is widely used in glass manufacturing, semiconductor and other high-tech industries.

5.Mechanism sand: made by machine crushing and screening quartz, it can control the sand shape and particle size. It can be used to replace river sand.

6.Concrete sand: made from crushed concrete or aggregate, the particles are coarser, but it can also be used for building concrete.

Different types of sand have different properties and applications. The value of sand will also be high or low depending on the source, composition and grain size.

Ⅱ.The Density of Sand

Density, the mass per unit volume of sand (usually expressed as g/cm³ or kg/m³). The density of sand depends on its source, moisture content, mass and state.

Typical densities of sand in different states | |

| Loose sand (naturally accumulated, moved external forces) | 1442kg/m³ |

| Dry sand (dry, compacted by gravity and rainfall) | 1602kg/m³ |

| Packed dry sand (sand compacted by man or by machinery) | 1682kg/m³ |

| Wet sand (naturally compacted, with high water content) | 1922kg/m³ |

| Wet packed sand (compacted by man, saturated with water content) | 2082kg/m³ |

The density of construction sand is usually in the range of 1.4-1.6g/cm³. Sand with higher density has tightly arranged particles, fewer voids and better stability. However, low density sand is light and prone to movement or settlement.

Ⅲ.The Size of Sand

The particle size and distribution of sand can regulate its performance. Internationally in accordance with the size of the diameter of the sand, commonly used:

Coarse sand: size greater than 0.5mm (500 microns). Coarse sand can improve the strength of the material and facilitate drainage.

Medium sand: 0.25-0.5 mm (250-500 micron). Medium sand has a well-balanced grading and is mostly used for concrete mixing.

Fine sand: size less than 0.25 mm (100-250 micron). Fine sand fills small gaps and provides a smooth surface.

The rule of “Good Grading”

The right proportion of coarse-medium-fine sand results in the tightest possible build-up of sand. This also has the following advantages: It ensures good leveling of the mortar, making your walls smoother. This saves you money by drastically reducing the amount of cement used. This improves the compactness, strength and impermeability of your concrete.

IV .The Importance of Sand Density and Grain Size

The application of sand permeates many aspects of the functioning of society, and its density and grain size determine its suitability and functionality. Understanding these two parameters is a prerequisite for the value of sand to be realized. Below are the effects of sand density and particle size in different industries.

1. Construction

Construction is the core area of sand application. More than 80% of the world’s sand is used in this field, and the density and grain size requirements of sand are directly linked to engineering safety.

Concrete proportion design – reasonable matching of coarse, medium and fine sand can reduce voids and improve concrete strength and impermeability.

Slurry workability – this slurry is based on fine sand, which is easy to smooth and can improve the smoothness of the plastered surface.

Road construction – High-density sand is needed to safeguard the compaction of the roadbed, reduce the risk of settlement and create a smooth and stable surface.

Reclamation projects – the need for medium-coarse sand, both to ensure the drainage of the material, but also the need to resist seawater scouring.

2. Industrial Manufacturing

The density and particle size of sand directly determines the quality of the product and is mainly used in glass, casting and oil fracturing.

Glass manufacturing – this requires a density greater than 2.56g/cm3 of high purity quartz sand, so as to avoid the emergence of air bubbles to destroy the product.

Foundry industry -This requires high-density sand casting moulds or prevents molten metal overflow during foundry work.

Oil Fracturing – This requires high density, high strength particles (“frac sand” or proppant) to keep the cracks open and allow oil or gas to flow out smoothly. The particle size and strength of the sand is one of the core parameters of the design program.

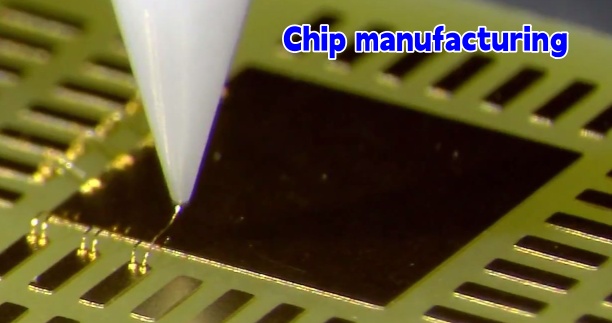

3. High-tech sector

In this sector, the sand parameters are the most demanding, and any deviation can lead to product obsolescence.

Chip manufacturing – the density and chemical composition of high-purity quartz sand is directly linked to the chip’s computing speed.

Photovoltaic – quartz sand with stable density is needed to guarantee the light transmission and signal transmission rate of photovoltaic products.

Aerospace materials – quartz sand made of fiberglass material bonded with resin can be used in the extreme environment of space.

New energy – impurity-free, high-purity sand materials can improve the performance of battery shells and precision components.

4. Environmental protection and daily life

Water filtration – Filter sand particle size control at 0.5-1.2mm, high density sand can trap impurities and uniform filtration.

Ballpark bunker – highly uniform medium and fine sand (0.25-0.5mm) is required. This sand layer is easy to maintain and is not easily sloughed.

Agriculture – Coarse sand can improve the permeability of clay soil, fine grit added to poultry feed to assist digestion.

Cosmetics – Scrubs are made using very fine sand, which gently exfoliates and does not damage the skin.

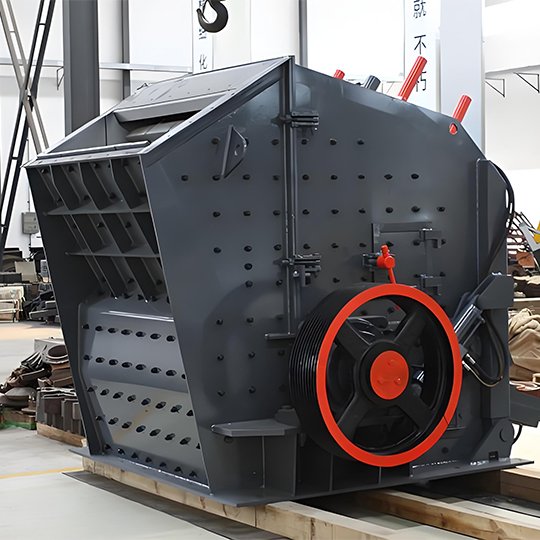

V. Sand Processing Recommended Equipment

If you want to get sand with ideal density and particle size, professional processing equipment can help you realize it.

1.Crushing and sand making equipment: Impact crusher and sand making machine can crush your large stone material and make mechanism sand. Different parameters of the equipment can control the particle size and produce sand with reasonable grading.

2.Screening equipment: vibrating screen. Different screen aperture can be used for particle grading, to separate out the coarse, medium and fine sand you need.

3.Cleaning equipment: spiral sand washing machine. This equipment can help you remove the dirt, dust and other impurities in the sand and improve the purity of the sand.

4.Purification equipment: you can improve the quality of sand through the beneficiation process. Magnetic separator and flotation machines can remove impurities and enhance the density of sand to meet the product demand of downstream manufacturers.

5.Dewatering equipment: thick force dewatering machine, drum dryer. These equipment can help you reduce the water content of sand for subsequent processing. This is the recommended equipment for processing sand in humid areas.

Conclusion

Sand is tiny, but it is vital in nature and human society. To maximize its value, you need to precisely control the density and particle size. Meanwhile, the demand for artificial sand is gradually rising, and choosing the right processing equipment can help you get more economic benefits. Contact Sandreck for more information.

FQAs

Q: Why can’t desert sand be used for construction?

A: The main reason is that the particle size and shape are not suitable. Desert sand particles are too fine and the surface is very smooth, it is difficult to bond with cement to form a solid concrete structure; secondly, it has a single grading and large void ratio, the strength and durability are not up to standard.

Q : Can mechanism sand completely replace river sand?

A: Under modern technology, high-quality mechanism sand can completely replace river sand to make high-strength concrete with better performance. Mechanism sand particles are angular and have a stronger bond with cement.

Q: How to regulate the particle size and density to meet the standard in the production of mechanism sand?

A: Adjusting the rotating speed of your sand making machine, the aperture of screen mesh, and grading with a vibrating screen can get the desired particle size. You can also remove impurities with the help of a spiral sand washer to improve the density of sand. Sand with high water content can be dewatered with a drum dryer to ensure that the density is stabilized in the standard range.

Q: Is higher sand density better?

A: Not necessarily, it should be selected according to the application. In areas where lightweight insulation is required, low density sand is instead the best choice. However, in construction projects, sand with higher packing density is usually chosen.