When it comes to rock crushing, it is well-known that compression machines take the lead while impact-style machines are based on principles of explosive, dynamic action.

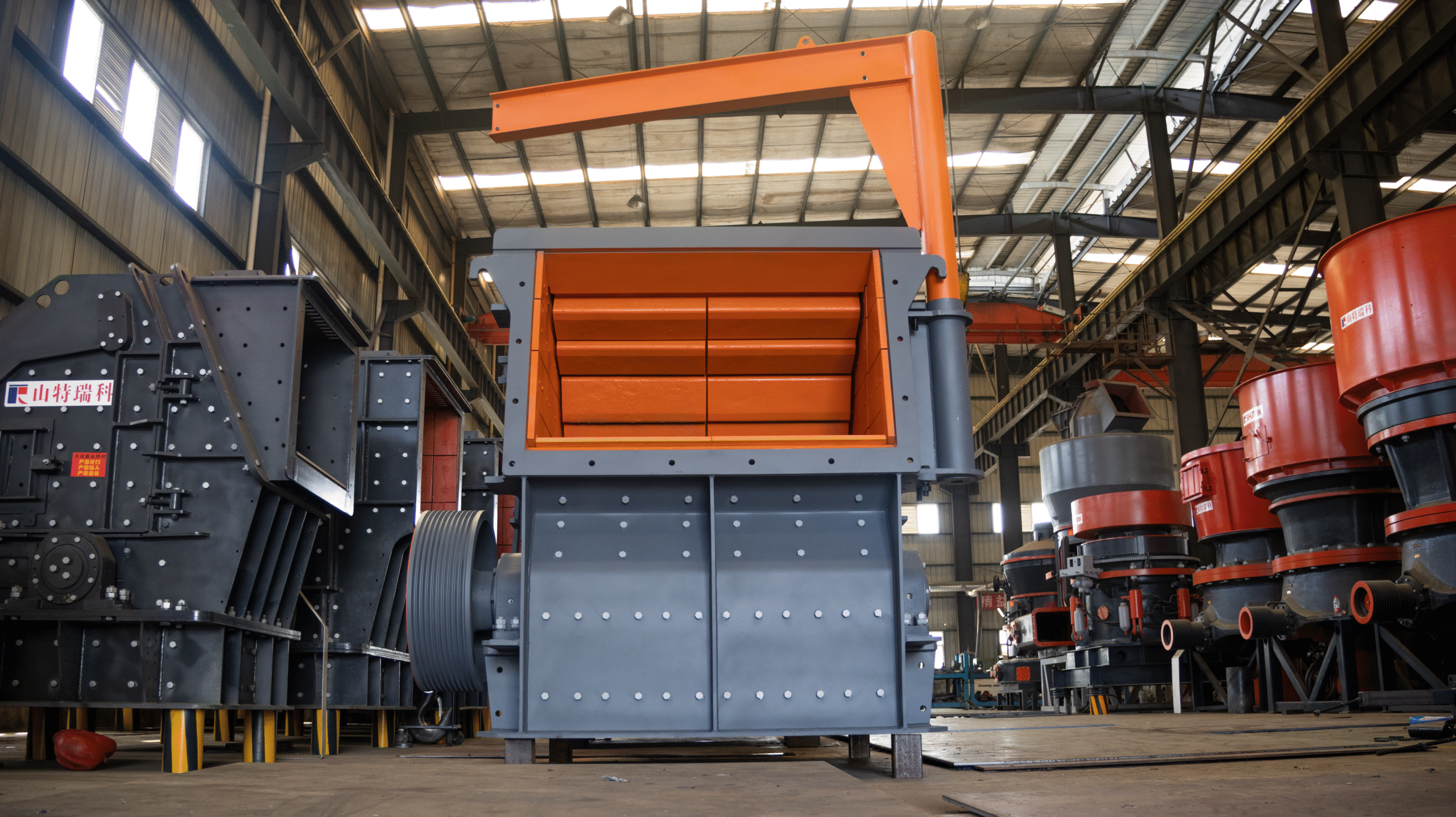

This guide, fueled by Sandreck’s industry expertise, will help you cut through the rocks and investigate the Impact Crusher by exploring the types, workings, and applications of these machines.

The Core Principle: Kinetic Energy and Impact

At the heart of an Impact Crusher’s operation is a simple law of physics: kinetic energy equals 1/2 mass times velocity squared (KE = ½ mv²).

This means that speed is exponentially more important than mass in generating crushing power.

An Impact Crusher leverages this by accelerating the feed material and violently throwing it against stationary surfaces (breaker plates) or other rocks (in a rock-on-rock configuration), causing it to shatter along its natural fissures.

This results in excellent product shape and high reduction ratios.

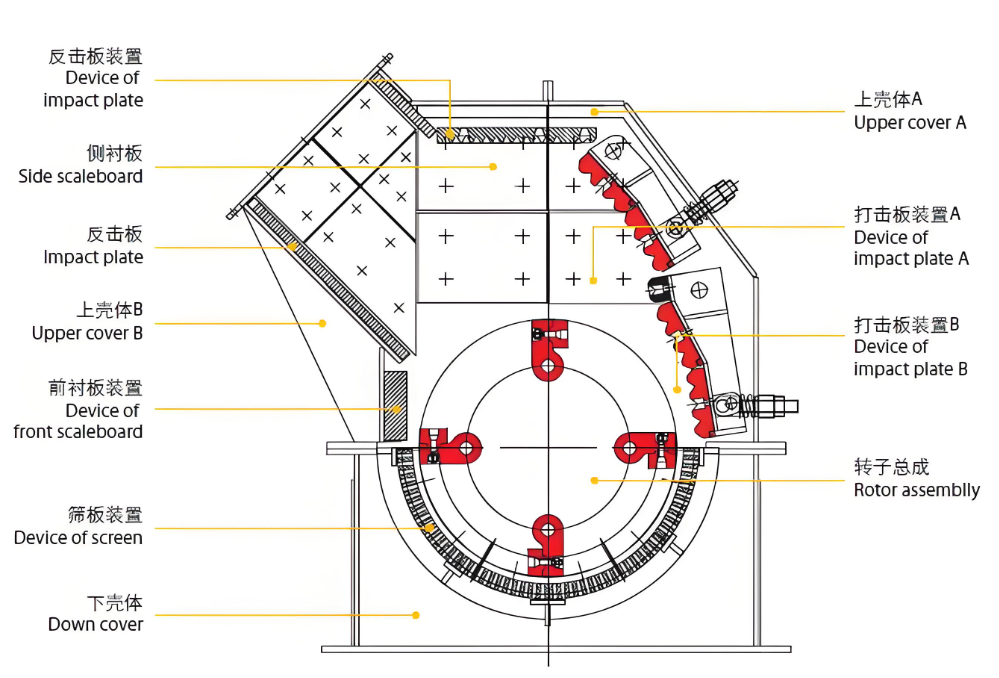

Impact Crusher Parts

Let’s discuss the main parts of the crusher. Understanding how a machine works is always easier after breaking down the information into parts.

1.Rotor: The rotor is the main part of the crusher, a heavy duty steel drum, with fixed or interchangeable blow bars or hammers, that rotates with a speed of 500 – 800 RPM allowing the rotor to create kinetic energy to fracture rock.

2.Blow Bars: Blow bars are considered the wear parts that are located on the rotor. Blow bars act like hammers on the feed material as it is moved through the rotor and launched away.

3.Impact Aprons / Breaker Plates: Impact aprons, or breaker plate, are the fixed or adjustable plates surrounding the rotor.

The incoming sort of rock is thrown against the impact aprons or breaker plates and creates the secondary crushing. The gap with the adjustable impact aprons is adjusted to keep the appropriate size for the final product.

4.Feed Opening: The feed opening is where the material enters the crushing chamber or system; this is frequently seen with a feeder conveyor to feed the material into the crusher.

5.Hydraulic System: Most modern rock crushers use a hydraulic system to safely open the crusher housing for access and maintenance, but the system also acts through the position of the impact aprons to size the product correctly.

The Two-Stage Crushing Process: Impact and Attrition

The operation of an Impact Crusher is a rapid, two-fold process that happens in milliseconds.

- Primary Impact (The First Blow):

As large rocks enter the feed opening, they are met by the spinning blow bars on the rotor.

The blow bars strike the rocks, transferring a massive amount of kinetic energy.

This initial impact shatters the rocks and propels them violently towards the primary impact aprons.

- Secondary Crushing (The Rock-on-Rock Anvil):

This is where the magic happens for product shape.

The material ricochets off the primary aprons and is thrown back into the path of the rotor.

On its return journey, it collides with other incoming rocks in a process known as “rock-on-rock” attrition.

This repeated, high-velocity collision between rocks further breaks them down and knocks off weak edges, creating the highly valued, well-shaped, cubical product that Impact Crushers are famous for.

Finally, smaller material that has reached the desired size passes through the gap between the rotor and aprons to be discharged.

Why Choose an Impact Crusher—Advantages for Modern Operations

Understanding the mechanism reveals the key benefits:

Excellent Product Shape: Produces a cubical product ideal for asphalt and concrete.

High Reduction Ratios: Can significantly reduce large feed material in a single pass.

Versatility: Can handle a variety of materials, including soft to medium-hard rock and are champions in recycling (concrete, asphalt).

Adjustable Output: Easily control product size by adjusting the apron gap or rotor speed.

Maximize Your Impact with Sandreck

The extreme efficiency of an Impact Crusher deserves extreme wear parts, as the high speed which continuously strikes and wears the blow bars and apron is an aggressive and relentless cycle.

While certainly achievable, it is crucial to understand that none of this impact testing is possible without a high-quality component.

Engineered and fabricated wear parts, specifically blow bars in high-performance impact crushing applications, are minimalist in terms of quality.

Sandreck specializes in wear parts designed to perform under the most demanding applications. Our blow bars are manufactured using advanced alloys and composites to provide the highest impact resistance for regarding wear/composites and the longest life, therefore lowering cost per ton and decreasing downtime and changes.

Contact us now for your own project!