In aggregate processing and mining, efficiency and reliability are undeniably vital. While out of all the types of crusher, the Cone Crusher offers the best quality.

You may be asking how a Cone Crusher does this level of size reduction – accurately? In this article, we will explain the principles, parts, and stages of operations relying on the knowledge and expertise of the crushing professionals at Sandreck.

The Fundamental Principle: Compression is Key

At its core, a Cone Crusher operates on the simple yet highly effective principle of compression crushing.

Unlike Impact Crushers that use hammers to smash rock, a Cone Crusher squeezes the material between two surfaces: a moving mantle and a stationary concave liner.

This method applies immense, continuous pressure to the rock, causing it to fracture along its natural fault lines.

This results in a more cubical and uniform end product, which is highly desirable for applications in construction and asphalt production.

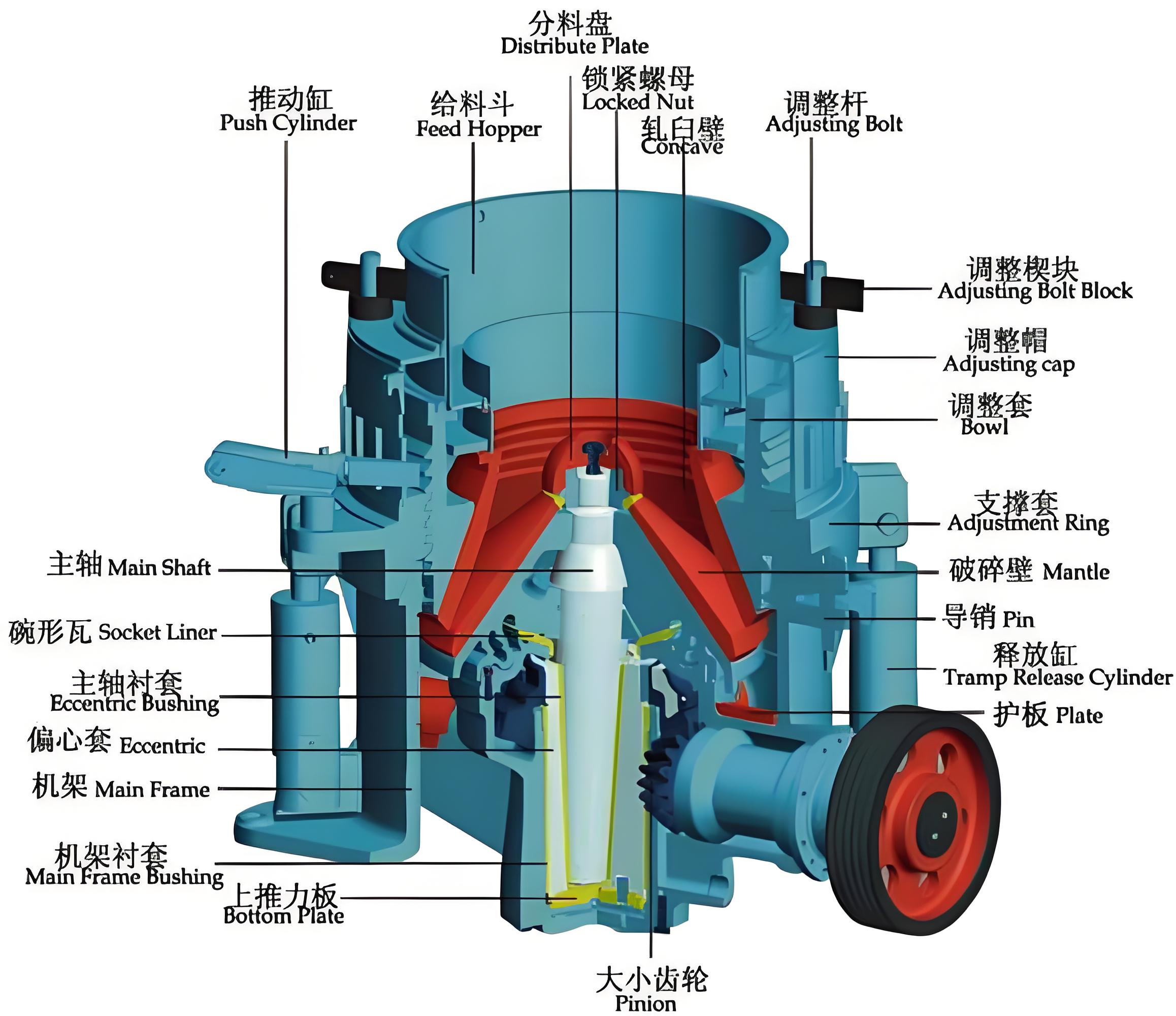

Deconstructing the Cone Crusher

To understand the procedure, it is valuable to understand the main components of a Cone Crusher.

1.Mantle: The main component a wear part, a cone on a rotating shaft that is gyrating. This gyrating motion is the motion that is used to crush the rock.

2.Concave (or Bowl Liner): The outer stationary surface which wraps around the right mantle. The gap between the mantle and concave is where the “crushing” happens – it is called the crushing chamber.

3.Main Shaft:The centre shaft where the mantle is bolted and where the power is transferred, from the eccentric assembly, to the mantle.

4.Eccentric Assembly:The principal mechanism that creates the gyratory motion. Mechanism used to create circular movement to the main shaft (and the mantle) creating oscillation in the mantle and compression of the rock.

5.Feed Hopper:The entry point to put the raw material into the crusher.

6.Hydraulic System: This is modern Cone Crushers most critical system, enabled the setting of the crusher at full operating load, also allows overload protection by raising the mantle, allowing the uncrushable material (tramp iron) to pass through the machine without destruction.

The Crushing Process: A detailed, Step-by-Step Process

You can picture a Cone Crusher functioning in a continuous cycle, like this:

Feeding: The crushing process starts with large rocks (feed matter); large rocks are gravity-fed from the top of the screen to the feeder-hopper of the crusher. The feed material travels down into the crushing chamber.

Compressive stress and fragmentation: While the mantle is spinning in a circular motion within the concave, the mantle will move closer to and farther from the concave walls.

When the mantle moves towards the concave, it powerfully compresses the rock trapped between that there are a limited number of ways to evade copmpressive stress, and they break.

Progressive crushing: The crushing chamber has a specific geometry. The gap between the mantle and the concave is wider at the top of the chamber and progressively narrower towards where the discharge occurs.

The rock gets crushed several times as it travels downward in the chamber.

At the top, rocks will get crushed into coarse fragments; as they move downward, they will be crushed into progressively smaller pieces before the discharge point.

Discharge: When the crushed material is sufficiently small to navigate through the narrowest gap at the bottom of the crushing chamber (this point is referred to as the closed-side setting, or CSS), the material is ejected from the Cone Crusher.

The CSS is an adjustment that is very important. It directly determines the final product size. When the CSS is smaller, the output is finer.

Why Cone Crusher Operation is Important to Your Bottom Line

Learning how a Cone Crusher works isn’t just technical knowledge, it is knowledge that leads to controlling your entire operation.

Understanding how to correctly set the CSS and operate under consistent feed, and liner maintenance while also all of these items also control:

Product Quality: A correctly set Cone Crusher will produce a well shaped, cubical product that is valued more in the market.

Capacity and Throughput: A good crushing operation gets you the most tons or hours, giving you more value for your dollar.

Wear Part Life: By operating the machine at its designed parameters you are maintaining the wear on the mantle and concave liners in a way that is limiting your unnecessary costs per ton.

Partnering with Sandreck for Your Crushing Solutions

The first step towards optimal performance is understanding how your equipment works.

At Sandreck we have the knowledge to help. Not just in parts, but also parts that will help maintain your Cone Crushers operational.

For more help and valuable insights with industry-leading crushing solutions, consult the experts at Sandreck.