In today’s rapid urbanization and infrastructure development, construction waste is one of the fastest growing waste streams in the world.

Traditional recycling machines are typically not optimized for these types of objects, which leads to breakdowns and inefficient processing times.

If you are a distributor for a building reconstruction project, then this article can help you better understand an efficient and cost-saving equipment.

Key Mining Equipment Completing and Converting Waste Recycling

1.Jaw Crusher

If you’re looking to process large volumes of construction waste (like concrete beams, floor slabs, and masonry blocks), the Jaw Crusher is the top choice for primary crushing.

The operation is simple, and consists of a movable and a fixed jaw that periodically compress and crush the material like a “vice.”

The Jaw Crusher has a robust design, is high capacity, can handle a lot of weight, and has moderate maintenance costs as well.

However, the shape of the product is usually poor and flaky, and it is loud, very loud, when in operation! In a Mobile Crusher, the Jaw Crusher is often the “primary crushing” machine for concrete.

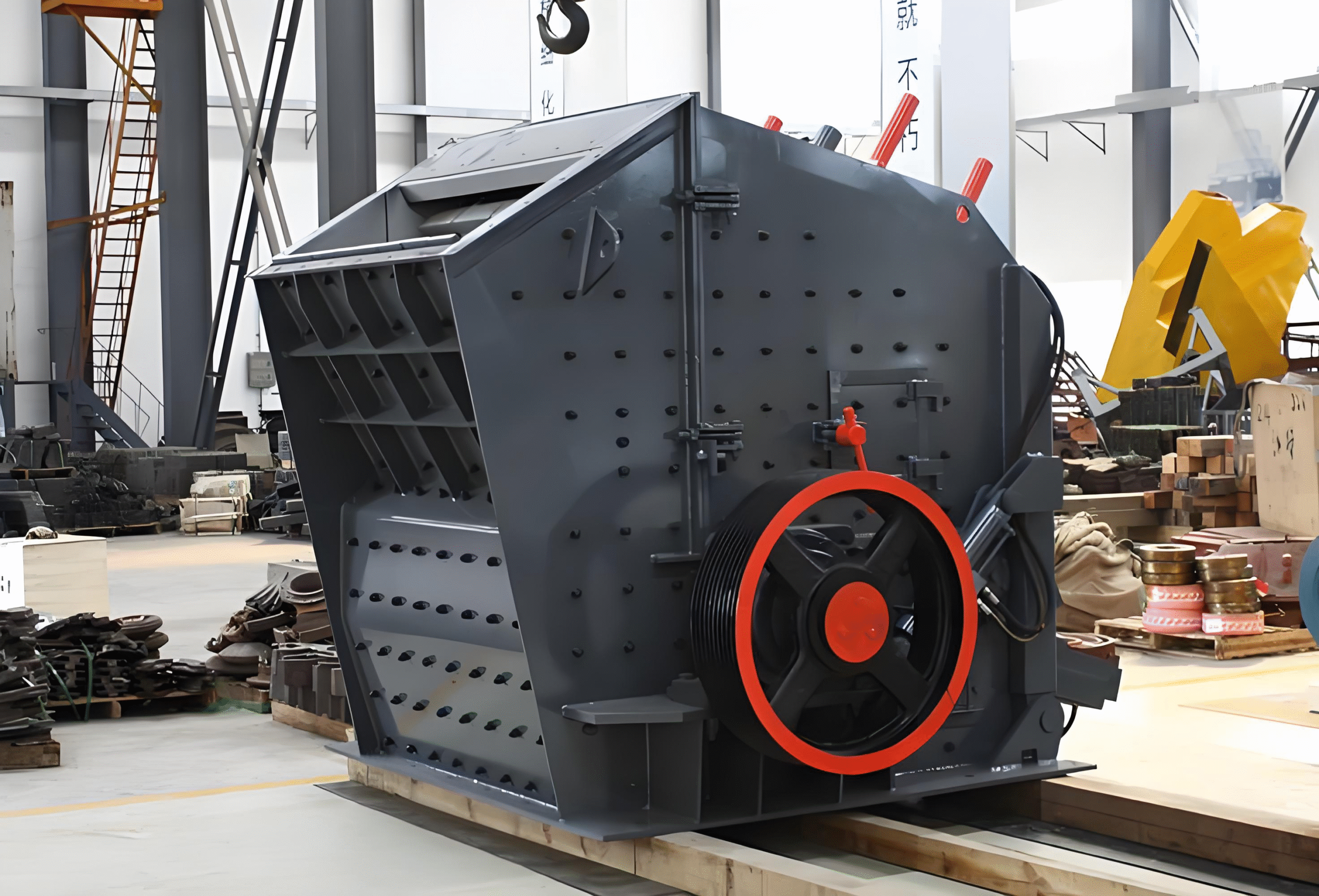

2.Impact Crusher

If you have high demands for the particle shape of the finished aggregate, the Impact Crusher is the best option for secondary and fine crushing.

It works by impacting the material when a high speed rotating rotor comes into contact with it and then strikes the impact plate for crushing.

This machine is generally used for medium-hard materials such as concrete and asphalt.

The most significant advantage of the impact crush is producing a fine and cubic product shape, which is great if you are looking to produce quality recycled aggregates.

Also, it has a high crushing ratio, which is another big advantage. It should be noted that the hammer and impact plates wear quickly, therefore the maintenance costs will be higher. The Impact Crushers are not well suited for extremely hard or sticky materials.

3.Cone Crusher

When dealing with construction waste that is particularly tough, it is possible that which a cone often would be a better fit.

A Cone Crusher crushes the material though squeezing and bending the material in the space formed between its static and dynamic cones.

From the perspective of advantages, it has good resistances to wear and has a long service lift.

This ultimately leads to lower long-term running costs and higher production efficiency, and consumes a minimal amount of energy.

On the negative side, the particles produced are considerably poorer than an Impact Crusher, and also the purchase price can be more expensive than for an Impact Crusher; and lastly it is much more sensitive to material that contains water and mud, which can clog the system easily; and is better suited for a fixed production line than mobile.

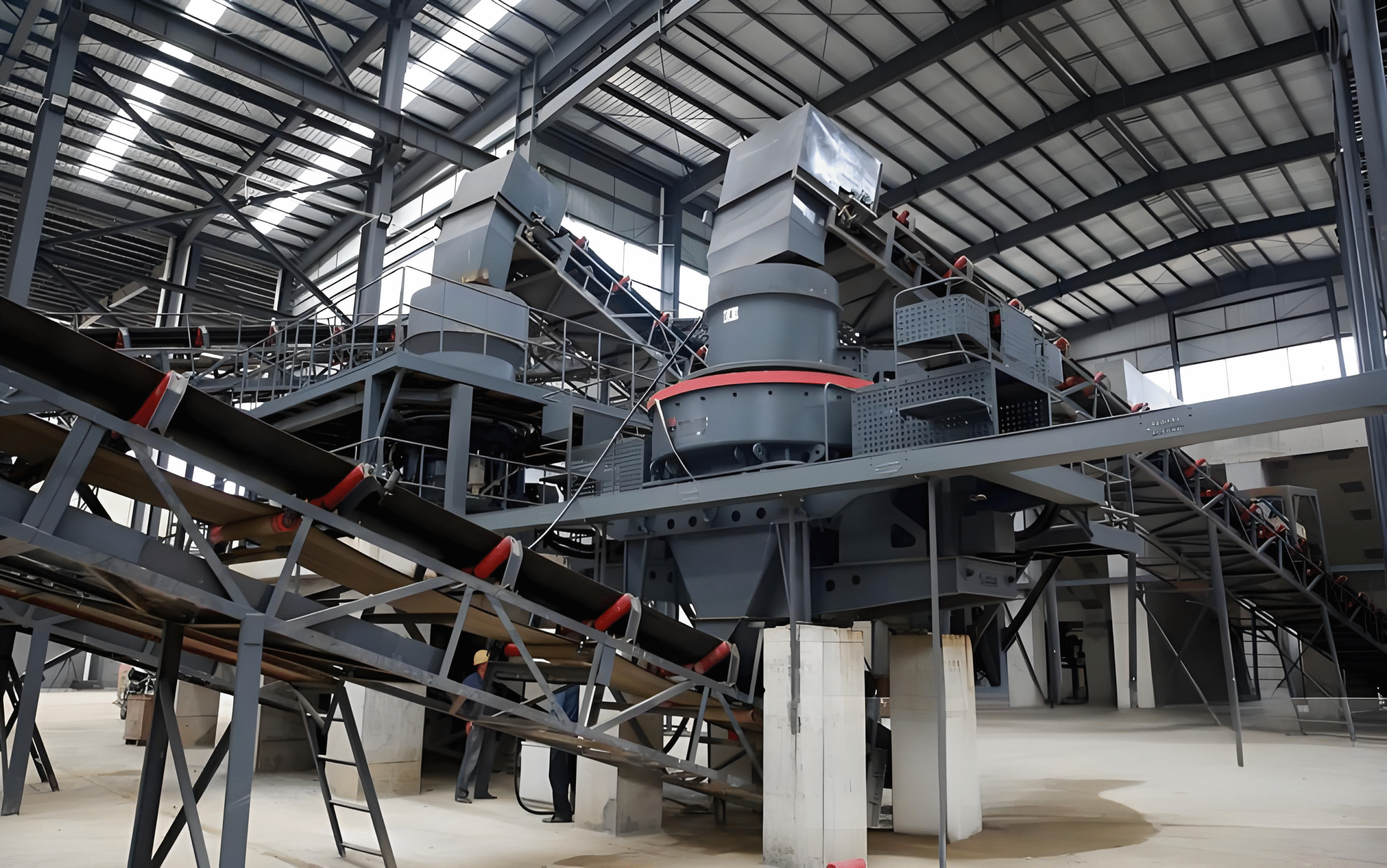

4.VSI Crusher

For extended small stone crushing or sand production in construction recycling, your option would be a VSI Crusher (or Sand Making Machine).

Unlike other options, it operates under a “stone-on-stone,” (or “stone-on-iron”) principle and relies solely on impact forces for both crushing, and shaping.

It produces quality returned sand with good particle shape and gradation, and produces crushing and shaping in one operation.

Feeding size will be your first limitation so you will need a Jaw or Impact Crusher that can produce small sizes as a primary Crusher before the sand maker.

5.Mobile Cruesher

Ultimately, if fast flexibility is your main concern, then a Mobile Crusher is your best comprehensive solution.

It is not just a Crusher in a concrete sense but a complete system that can include any of the above Crushers (for example, a Jaw and an Impact Crusher) as well as a feeder, screen, etc. all in one vehicle-mounted chassis.

The best part is that you can drive the Mobile Crusher directly to the demolition site for use – you can process onsite and utilize the material right away – also you will significantly reduce transportation cost of material and you can relocate so much easier.

Depending on the conditions you can go with a crawler type system for off-road performance or tires as a relative cost savings.

Benefits of Mining-Grade Equipment in C&D Recycling

1.In terms of performance

Unparalleled Durability and Reliability Mining-grade equipment is designed to run 24 hours/day, 7 days/week, in the most extreme conditions on earth.

In the construction waste recycling context, that means:

- Less downtime and maintenance costs

- Greater longevity of components when using abrasive materials

- Consistent performance under varying feed conditions

- Greater Processing Capacity Mining equipment has a vastly higher processing capacity than recycling specific equipment.

Versatility in Material Handling Mining equipment are capable of handling the diverse material stream typically found at C&D sites when rubble is present (from concrete to asphalt to soil to bricks etc.) without needing specialized machines.

2.In terms of The Environmental Impact

1) The use of robust mining equipment in construction waste recycling creates a powerful circular economy model:

2)Reduced Landfill Use: Diverting millions of tons of material from overcrowded landfills

3)Natural Resource Conservation: Creating high-quality aggregates that reduce the need for virgin material extraction

4)Carbon Emission Reduction: Lowering transportation needs and avoiding emissions from virgin aggregate production

Conclusion

As urbanization accelerates and environmental regulations tighten, the role of robust mining equipment in recycling will only grow. Advanced automation, artificial intelligence for material recognition, and even more efficient crushing technologies are already transforming how we approach waste processing.

This article mainly describes the position of the construction waste crushing station in the construction reconstruction industry.

Sandreck is a professional manufacturer of crushing equipment with a history of 20 years. If you need a customized solution, just contact us!