Dolomite is an important resource of calcium and magnesium on Earth. It is very abundant and plays an important role in nature and human life. The industrial value of dolomite is especially prominent, and the processed products can be applied to a variety of industries. Have you ever faced production challenges due to inconsistent ore quality? Or struggled to enhance product value?

Whether you are a mine manager dealing with mineral processing difficulties or a procurement decision-maker seeking high-quality raw materials, understanding dolomite can be highly beneficial. This article will take you through five key aspects of dolomite, helping you fully understand its resource value and applications.

Ⅰ.What is Dolomite?

Dolomite is a mineral or rock primarily composed of calcium magnesium carbonate [CaMg(CO₃)₂].

| Major Components | Accompanying Minerals | Color | Hardness | Crystal Shape |

| Calcium (Ca) Magnesium (Mg) Carbon (C) Oxygen (O) | Calcite 、Chalcopyrite、Galena、Persilite、Gypsum、Quartz、Feldspar, etc. | Colorless 、White、Gray Pink、 Brown, etc. | 3.5-4 | Trigonal system、 Rhombohedral |

Dolomite’s color can vary from white and gray to pink depending on impurities. Unlike limestone, which is mainly calcium carbonate, dolomite contains both calcium and magnesium, giving it unique chemical and physical properties.

A simple way to distinguish it from limestone is by using dilute hydrochloric acid. Dolomite will bubble, but much slower than limestone, due to the milder reaction of magnesium with acid.

II. How is Dolomite Formed?

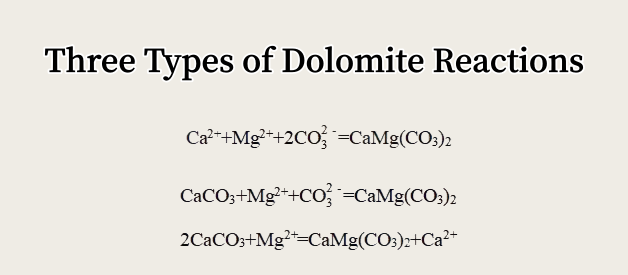

The process of dolomite formation is known as “dolomitization” and involves chemical changes of substances. There are mainly the following ways:

1.Primary deposition: In high temperature, high salinity seawater (e.g. tropical lagoons), dolomite can be formed by direct precipitation from water, but this is relatively rare.

2.Secondary Accounting: This is the most important way of dolomite formation.

Initial deposition: limestone or lime mud is deposited in the marine environment.

Magnesium enrichment: Magnesium-rich fluids (usually seawater) penetrate into the limestone (mainly composed of calcite).

Chemical reaction: Magnesium ions replace calcium ions in the carbonate structure.

Crystallization: crystallization to form dolomite.

3.Microbial Activity: Recent studies show that certain bacteria and microorganisms can promote dolomite formation.

Dolomite resources are found worldwide, with notable mines in the Midwestern USA, Ontario (Canada), Switzerland, Mexico, and Pamplona (Spain). In addition, the famous Italian Dolomites are also made of dolomite.

Ⅲ. Is Dolomite a Mineral?

The answer is: dolomite can be either a mineral or a rock, both concepts are different but closely related.

From the mineralogical point of view, dolomite is an independent mineral. It has a fixed chemical composition – calcium magnesium carbonate (CaMg(CO₃)₂), a unique crystal structure (tripartite crystals), and physicochemical properties.

Petrologically, dolomite is a sedimentary or metamorphic rock dominated by dolomite minerals (>50%).

Simply put, dolomite minerals are the core component of dolomite, and dolomite is a natural aggregate of dolomite minerals. In industry, the term “dolomite raw material” is often used to refer to dolomite ore.

IV. How to Process Dolomite?

Processing dolomite involves converting natural ore into products suitable for various downstream applications.

1. Crushing and screening

After mining, you can use equipment like jaw crushers and impact crushers to crush large dolomite ore blocks to the appropriate size. The crushed material is then graded with vibrating screens to produce different sizes of gravel to meet the needs of subsequent processing or direct application (such as construction aggregates).

2. Grinding and sorting

If you need dolomite products in the form of fine powder (used in agriculture, glass, etc.), the screened crushed stone is fed into Raymond mill, ball mill and other grinding equipments, then it can be ground into fine powder; and then the iron impurities are removed through magnetic separation, and other minerals such as quartz, clay, and other minerals are separated through methods such as flotation, re-election, and so on, so as to improve the purity and whiteness of your products.

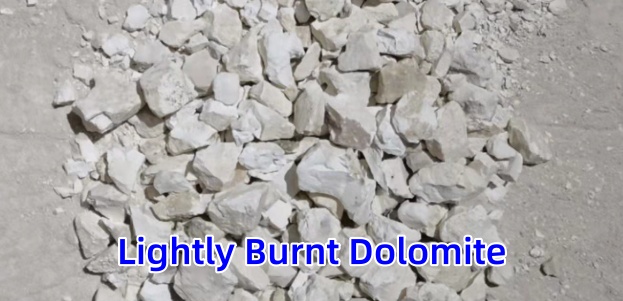

3. Calcination processing

Calcination of dolomite is a key component in the production of high value products at the mine. High temperature heating alters the chemical composition and physical properties of dolomite to produce calcined dolomite with high activity.

High grade dolomite lumps or pellets are put into a rotary kiln or vertical kiln for calcination at a controlled temperature of 900-1100℃. The product you get is called Calcined Dolomite or “Lightly Burnt Dolomite”, and its main component is a mixture of calcium oxide and magnesium oxide. It is also highly reactive.

If you calcine it at higher temperatures (about 1500-1800°C), you get dead-fired dolomite. It has a dense structure, stable volume and high resistance to hydration, and is mainly used in high-grade refractories.

4.Storage

The calcined product will be hydrated and deteriorated once it comes into contact with humid air, so you need to store the product in a dry and ventilated environment so that you will not lose your benefits.

Ⅴ.What Are the Uses of Dolomite?

Dolomite’s unique combination of calcium, magnesium, and physicochemical stability makes it valuable across multiple industries, offering you significant economic benefits.

1.Construction

– Used directly as building stone.

– Crushed into aggregates for concrete and asphalt.

– Polished for flooring and wall cladding.

2.Industrial field

Dolomite powder can be used as refractory material and co-solvent in steel production to enhance the hardness and toughness of steel. It can also be used in the smelting of copper, aluminum and other non-ferrous metals, to play the role of desulfurization, dephosphorization and protection of furnace lining.

3.Agricultural field

– Fertilizer: Provides calcium and magnesium for crop growth, boosting yields.

– Feed Additive: Purified dolomite powder supplements calcium and magnesium in livestock feed, promoting bone development.

– Soil Improvement: Adjusts soil pH and can increase crop yields by 15–40%.

4.Glass products

Dolomite is rich in magnesium oxide, you can use dolomite to reduce the cost of the glass manufacturing process. Dolomite powder has the function of fluxing, which can improve the strength and stability of glass.

5.Ceramic products

– Used in ceramic bodies and glazes to replace talc and calcite, helping you to reduce the firing temperature of the raw billet, while improving the transparency of the finished product.

– Dolomite-based glazes reduce smoking and crystallization, ensuring stable firing.

6.Magnesium-containing cement

If you’re looking for a cement material with excellent performance, consider magnesium-containing dolomite cement. It has the advantages of fast solidification and hardening, high compressive strength, good elasticity, and strong abrasion resistance, etc. It can help you efficiently complete the tasks of laying floor tiles, fast-setting pavement construction, and pavement crack repair.

7.Magnesium smelting

In the production process of magnesium metal, you can choose dolomite as the direct raw material, which contains about 20%-22% of magnesium oxide. The unique calcium and magnesium double oxide structure of dolomite can effectively prevent the material from sticking and crusting during the reduction process, ensuring the smoothness and efficiency of your production process.

8.Environment

Calcined dolomite has the advantages of low cost and no secondary pollution. The use of dolomite can reduce sulfur dioxide emissions from power plants; it can also neutralize acidic water and remove heavy metals.

9.Food and pharmaceutical field

Food additives: high-purity dolomite powder can be used as a food anti-caking agent, acidity regulator, used in seasonings, baked goods and so on.

Pharmaceutical raw materials: it can be used to produce calcium and magnesium supplements for health care products or medicines, and can also be used as a filler for pharmaceutical preparations.

CAUTION

Processed dolomite sand and powder may contain hazardous substances like asbestos and heavy metals (e.g., aluminum, arsenic, lead, mercury, nickel). Ensure thorough processing and compliance with safety standards before environmental or human use.

Conclusion

The value of dolomite stems from its unique composition and properties. Whether it is for mineral development, industrial production or agricultural applications, if you have a deeper understanding of dolomite’s core knowledge, you will be able to unleash its resource potential more fully and capture more economic value.

If you need scenario-specific dolomite processing solutions or technical advice, Sandreck can answer your questions.

FAQs

Q: The whiteness of dolomite after beneficiation is not up to standard.

A:Whiteness issues are often due to impurities. Use wet magnetic separators for iron impurities and shaking tables for quartz. These physical methods are cost-effective and can improve whiteness by 5–8%.

Q: How to remove iron from dolomite products economically and efficiently?

A: We recommend the synergistic process of “strong magnetic separation + acid washing”. Dry high-intensity magnetic separation removes most iron, followed by controlled citric acid leaching to achieve over 90% whiteness with manageable wastewater.

Q: What is the cost-effective equipment for processing dolomite in small and medium-sized mineral processing plants?

A: You can choose a jaw crusher, spiral washing machine, wet magnetic separator, vibrating screen, less investment and easy to operate, suitable for your daily processing capacity of 50-200 tons of demand.

Q: How to separate dolomite and calcite effectively when beneficiation?

A: You can use the flotation method to separate. With the addition of a special conditioner, the dolomite will float with air bubbles and the calcite will remain in the slurry. This method can increase the purity of dolomite to more than 90%.

Q: Is there any value in mining low grade raw dolomite?

A: If the dolomite content is ≥60%, it can meet the demand for building materials and fluxes after being purified by washing + magnetic separation. The mining cost of this kind of ore is low, and you still have considerable profit after batch processing.