Iron and steel is the most widely used metal, accounting for 95% of all metals used each year. Not only does it support industry, but it also has a big impact on our lives. Iron and steel are used in everything from furniture for everyday use to building cars and bridges.

Iron ore is the raw material used to produce steel products. As the person in charge of the beneficiation plant, understanding the type of iron ore is the key to cost control and resource utilization. This article will introduce you to the four main types of iron ore, and discuss the related beneficiation process.

Ⅰ.What Is Iron Ore

Iron ore is a naturally occurring rock or mineral from which valuable metallic iron (Fe) can be extracted. Iron ore is essentially a kind of iron-containing compound, iron will have a chemical reaction with other elements, so we see the color of iron ore varies.

There are over 300 types of iron ore in nature, but the main ones that are economically exploitable are magnetite, hematite, limonite and siderite. Of these, hematite and magnetite are the absolute workhorses. They vary in iron content, core characteristics, mining processes and market value.

II. 4 Types of Iron Ore

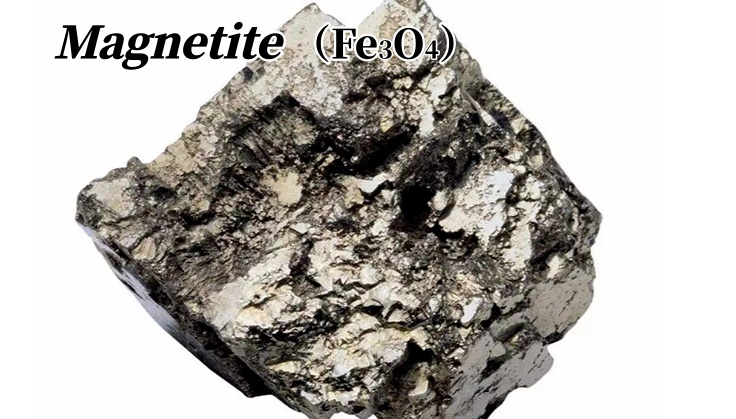

1. Magnetite – the best quality

Magnetite (Fe₃O₄) has the highest iron content of all iron ores, up to 72.4%, so it can be directly smelted to produce steel with few impurities and high quality. At the same time, it naturally has strong magnetic properties, through magnetic separation you can obtain a high quality concentrate with a grade of more than 70%, the most economical cost of beneficiation.

Magnetite is usually black in color and has a hardness between 5.5 and 6.5. Magnetite is not only widely used in the manufacture of steel, but is also often used in the production of materials for pigments, ceramics and electronic technology. Australia, Brazil, North America and Sweden have abundant magnetite resources.

2. Hematite – the largest reserves

Hematite (Fe₂O₃) is an important iron ore that can contain up to 70% iron but is not naturally magnetic. When the iron content exceeds 60%, this hematite is called “direct shipment ore (DSO)” and you can use it directly in smelting.

Hematite can be red, light red, or black in color, and usually has a hardness between 5.5 and 6.5. This ore can be used to make iron and is also widely used to make pigments and jewelry. Globally, Australia, Brazil and India are the major producers of hematite.

With its abundant and widespread reserves, hematite is the world’s largest and most important iron ore. You can judge by the color of the ore.

3. Limonite – medium performance

Limonite (FeO(OH)-n(H₂O)) is a mixture of several water-bearing iron oxide minerals such as acicular iron ore. It has a relatively low iron content, up to about 59.8%. Limonite has a high water content and usually needs to be pre-treated with dewatering before smelting.

Limonite has a wide range of colors, such as yellowish brown, dark brown, or dark gray. Its hardness usually ranges from 4 to 5.5. Despite its low grade, limonite can be used to make iron and is also used in the paint and construction industries. Limonite is widely distributed, but there are relatively few large-scale mines.

Due to its low yield and high water content, limonite has been used as a low quality iron ore. Your direct smelting of this iron ore is inefficient and costly, and it needs to be briquetted before it can be made into iron.

4.Siderite – Non-Magnetic Ore

Siderite (FeCO₃) is a carbonate-containing iron ore that is often symbiotic with other minerals (barite, quartz, etc.). It has a relatively low iron content, up to about 48.2%, the lowest grade of the major iron ore types and is not magnetic.

Siderite is mostly gray or yellow-brown in color, etc., and has a hardness between 3.75 and 4.25. This ore is used for smelting iron and steel, and is also a good raw material for making pigments because of its stable and unfading color. Most of the deposits of Siderite are formed in sedimentary or hydrothermal geological environments.

The most important feature of Siderite is that it is non-magnetic and the mineral does not contain harmful impurities such as sulfur and phosphorus, making the final product highly pure. Your type of this ore will need to be calcined first to break down the carbonate as a way to boost the iron content.

Quick Comparison Chart

| Magnetite | Hematite | Limonite | Siderite | |

| Iron Content | 72.4% | 70% | 59.8% | 48.2% |

| Magnetism | Strong | Weak natural | Weak | Non-magnetic |

| Hardness | 5.5-6.5 | 5.5-6.5 | 4-5.5 | 3.75-4.25 |

| Color | Black | Red, Light Red | Yellowish-brown, Grayish-black | Gray, Yellowish-brown |

Ⅲ. Iron Ore Extraction Process

The type of iron ore determines the choice of extraction process, which is also closely related to your economic benefits. The following are the recommended beneficiation processes for the four types of iron ores to help you realize efficient extraction.

1.Magnetite

The raw ore is fed into the jaw crusher for coarse crushing, and then into the cone crusher to complete the medium and fine crushing, to get 10-20mm ore particles. The crushed ore goes into a ball mill to grind to 0.074-0.2mm to ensure the full dissociation of the magnetite monomer. The qualified slurry is sent to the magnetic separator to get the concentrate, and finally you can get the high grade iron ore concentrate after dewatering.

Core equipment

Crushing equipment: jaw crusher (coarse crushing), cone crusher (medium and fine crushing), vibrating screen (grading)

Grinding equipment: lattice ball mill, spiral classifier

Beneficiation equipment: magnetic separator (weak magnetism)

Dewatering equipment: high-frequency dewatering sieve, chamber filter press, thickener

2.Hematite

After the raw ore is roughly crushed by the jaw crusher and finely crushed by the impact crusher, it enters the ball mill for grinding to dissociate the hematite from the chondrites. After grinding and grading, the slurry needs to add lime to adjust its PH value, then add water glass + tannin as inhibitor (to inhibit hematite), and then add ether amine cationic trapping agent, and stir well to make the agent and the slurry evenly mixed.

Finally, the slurry is fed into the mechanical stirring flotation machine to realize the efficient separation of hematite and veinstone. The flotation concentrate should be dewatered with a filter to meet your subsequent storage and transportation requirements.

Core equipment

Crushing equipment: jaw crusher, impact crusher

Grinding equipment: ball mill, hydrocyclone, high-frequency vibrating fine screen

Beneficiation equipment: slurry mixing tank, mechanical agitation flotation machine

Dewatering equipment: filter machine

3.Limonite

Firstly, the wheel sand washer is used to remove the muddy impurities in limonite to avoid clogging the subsequent beneficiation equipment. Then use a vibrating screen to separate out the coarse-grained ore (2-30mm) which meets the standard of re-election. The coarse-grained ore is then fed into a jigger to remove the veins. At this point, you can get a rough concentrate with an iron grade of about 45%.

Put the re-selected coarse concentrate into a ball mill and grind it down to 0.074mm, then use a strong magnetic separator to recover the fine-grained limonite, and you can get a concentrate with a grade of 55-60%. Finally, the concentrate can be used for smelting iron and steel by dewatering with a filter press.

Core equipment

Pre-treatment equipment: jaw crusher, wheel sand washer, self-centering vibrating screen

Re-election equipment: jigger

Grinding equipment: ball mill

Magnetic separation equipment: strong magnetic separator

Dewatering equipment: filter press, thickener

4.Siderite

The raw ore is crushed to 8-15mm by jaw crusher and cone crusher.Then sent to drum dryer to dry to the surface moisture ≤5%, to avoid lumps in roasting, which will increase the cost of subsequent processing. After drying, the ore enters the vertical kiln to remove the carbonate in the siderite and convert it into strong magnetic magnetite. After the ore is cooled, you can get the finished iron ore concentrate according to the magnetite extraction process.

Core equipment

Pre-treatment equipment: jaw crusher, cone crusher, drum dryer

Roasting equipment: shaft kiln

Grinding equipment: ball mill

Beneficiation equipment: magnetic separator

Dewatering equipment: filter press

Tailings Processing

Tailings can be recycled and processed into soil mixing aggregate, applied to building or highway construction, which not only enhances your mineral utilization rate, but also increases your income.

Conclusion

For the person in charge of mineral processing, identifying the type of iron ore is the basis for judging the mining value of the mine and formulating the beneficiation process. We hope that the four iron ore types introduced in the article can help you improve your resource utilization rate and mine efficiency.

If you have questions about mine development or processing optimization, Sandreck will be happy to answer them.

FAQs

Q: What type of iron ore is most beneficial in reducing my beneficiation costs?

A: Magnetite. It has strong magnetic properties and can be efficiently separated by simple magnetic separation. Your investment in equipment and operating energy is much lower than mining other ores, making it the most cost-effective choice.

Q: Hematite (DSO) can be fed directly into the furnace, how much investment can I save by buying raw ore?

A: High grade (>60%) hematite has high iron content and low impurities. By purchasing this kind of raw ore, you can save tens of millions of dollars of investment in the construction of the beneficiation plant and the subsequent milling costs. You only need to consider how to improve the utilization rate of the ore in the smelting process.

Q: Is there any value in mining non-magnetic rhodochrosite?

A: Yes. Through the “Roasting-Magnetic Separation” process, it can be converted into easily separable magnetite, thus obtaining a high grade concentrate.

Q: How can tailings from beneficiation be turned into income?

A: Tailings can be processed into concrete aggregate or building materials. This not only solves the problem of environmentally friendly stockpiling, but also increases the income of your mine.