Thickening and Dewatering Equipment

Sandreck’s Thickening and Dewatering Equipment delivers high-performance solid-liquid separation, optimizing water recovery and minimizing waste volume.

![]() Reduces water waste and supports sustainable resource management.

Reduces water waste and supports sustainable resource management.

![]() Lowers disposal costs and energy consumption, enhancing operational efficiency.

Lowers disposal costs and energy consumption, enhancing operational efficiency.

![]() Rapidly separates solids from liquids, improving productivity in mining and wastewater treatment.

Rapidly separates solids from liquids, improving productivity in mining and wastewater treatment.

Your Expert Thickening and Dewatering Equipment Supplier in China

Concentration and dewatering are crucial post-process steps in the mineral processing process. Together, they process the slurry after separation, achieving solid-liquid separation, recycling water, and obtaining a solid product that is easily transportable.

After the wet selection process, the concentrate tailings have a high water content. While the concentrate cannot be directly smelted, it will also increase transportation costs and operating costs, so subsequent thickening and dewatering operations are required.

As a Chinese mining machinery and equipment manufacturer, Sandreck has independently developed a series of thickening and dewatering equipment in response to the above situation.

The Thickening and Dewatering Equipment that our factory can sell includes Deep Cone Concentrators, Inclined Plate Concentrators, Filter Presses, etc. Each equipment has a complete range of models to fully meet your production needs of various ores and scales.

Product By Features

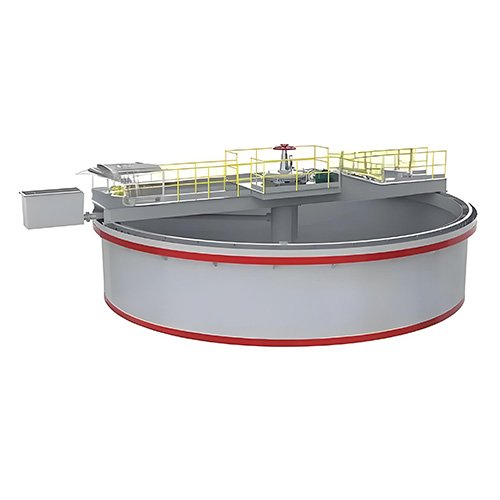

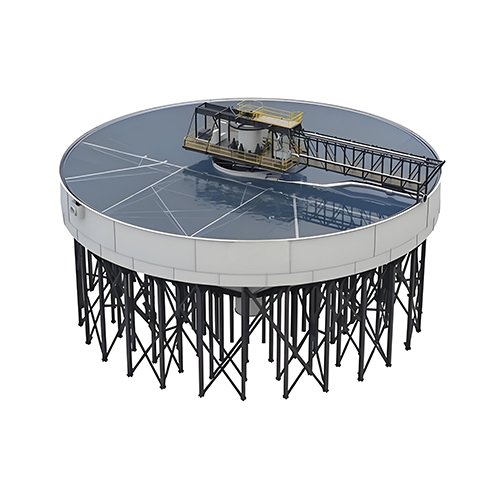

Efficiently concentrate solid-liquid mixtures through gravity settling, featuring a compact center-driven mechanism.

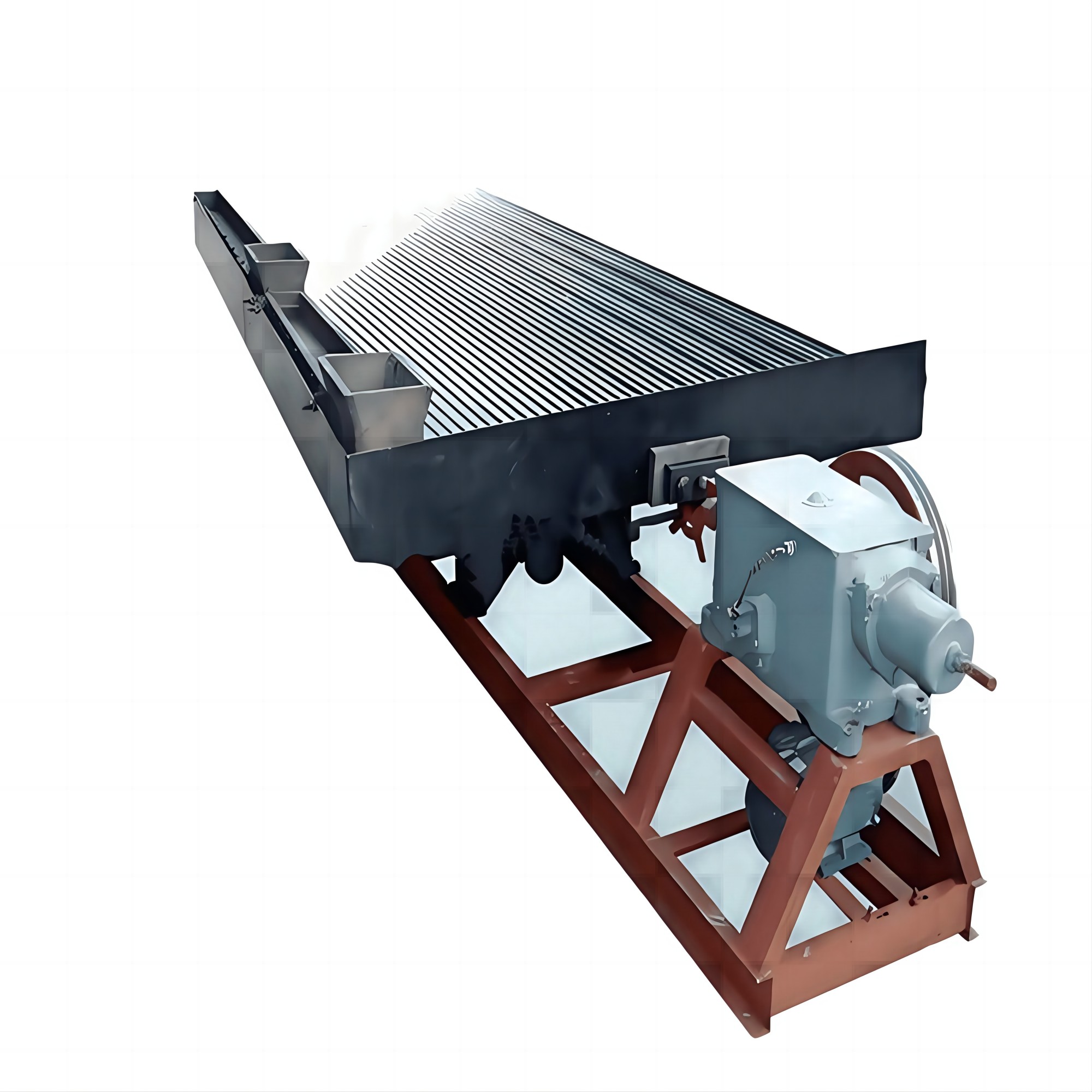

Dewatering treatment of wet and fine selection in ore dressing process.

Deep Cone Thickener is a high-dewatering thickening equipment for ore dressing plants.

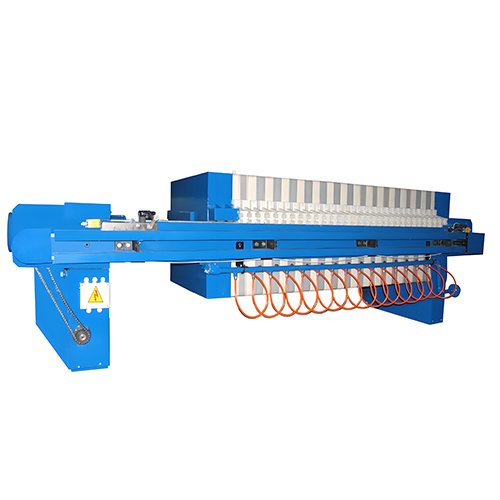

Press Filter is a commonly used separation equipment for solid liquid suspension, filtration precision of 1-50 microns.

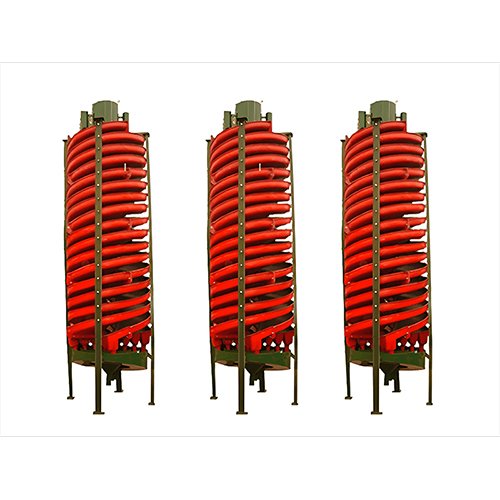

Uses centrifugal force to accelerate the sedimentation of ore particles.

Thickening and Dewatering Equipment Advantages

Sandreck’s thickening and dewatering equipment support continuous operation to meet the demands of high-intensity production.

Compared to the traditional device, Sandreck’s thickening and dewatering equipment reduces the water content of slag to less than 15%.

Sandreck’s thickening and dewatering equipment supports 24-hour autonomous operation to reduce manual intervention.

Sandreck’s thickening and dewatering equipment key components are made of stainless steel or high-strength alloy materials.

Sandreck’s thickening and dewatering equipment has a high mud cake content after dehydration, reducing sewage discharge.

As a professional thickening and dewatering equipment manufacturer, Sandreck can sell equipment at a low price and good quality.

Intelligent Control

Sandreck’s Thickening and Dewatering Equipment is equipped with an automatic control system that monitors concentration and adjusts discharge in real time, allowing for unattended operation and significantly reducing labor costs and operational complexity.

Thickening and Dewatering Equipment Is Widely Used

Sandreck high-quality Thickening and Dewatering Equipment is suitable for high-humidity materials such as sludge, tailings, and food waste.

It reduces the moisture content (60%-80%) through filtration and centrifugation to facilitate transportation or reuse. The selection needs to be combined with characteristics and pretreatment.

Why Choose Sandreck's Thickening and Dewatering Equipment?

Sandreck not only provides you with cheap Thickening and Dewatering Equipment, but also focuses on full life cycle service and customer experience.

Sandreck has a professional technical team to support the whole process, and cooperates with 50+ service points around the world to achieve a rapid response mechanism and minimize the risk of equipment downtime.

In addition, our thickening and dewatering equipment meets international environmental standards, and is your ideal choice for ore thickening and dewatering.

Complementary equipment for Thickening and Dewatering Equipment

The fine-particle slurry after classification is sent for concentration and dewatering, reducing the processing load on subsequent equipment.

The high-moisture concentrate or tailings from flotation undergo concentration and dewatering to increase density and reduce transport costs.

The wet concentrate (e.g., iron ore concentrate) after magnetic separation is treated through concentration and dewatering to meet standards for smelting and transportation.

Tailing from the shaking table are first concentrated and then dewatered, enabling the recovery of fine particles while reducing wastewater discharge.

Testimonials

After the equipment shut down, the filter cloth, filter plate or inner wall of the cyclone separator needs to be cleaned regularly to prevent the equipment from scaling; the operation data of the equipment should be recorded in time during daily operation.

The service life of Sandreck’s thickening and dewatering equipment is generally 5-8 years, and the actual service life may be shortened or extended according to your operating status, working conditions and other factors.

Before installing Sandreck’s Thickening and Dewatering Equipment, the foundation and power (water source) interface must be leveled to ensure normal use, and space for equipment maintenance must be reserved. For other situations, please refer to the Sandreck Concentration and Dehydration equipment product operation manual.

Related Products

Sandreck Jaw Crusher is the first and primary choice for the coarse crushing

Cone Crusher is suitable for sand and gravel aggregate production, mining operations.

Mineral separation equipment using particle motion differences in inclined flow