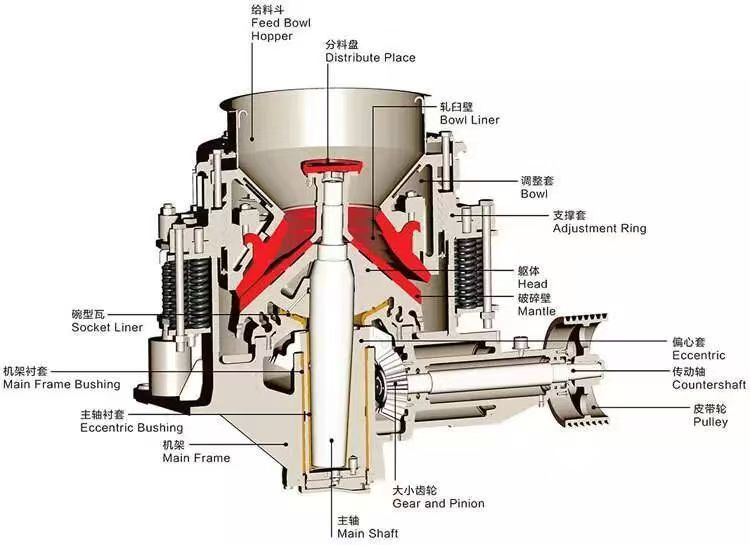

Your Cone Crusher is a critical piece of core equipment in the mining and construction sectors, and it is extremely important to have an efficient and stable equipment-based performance in your production process. Frequent work conditions and use eventually lead to failures, such as wear of components and failures in the hydraulic system. This leads to both loss of production time and increased cost for maintenance and production.

Next, I will recommend 7 maintenance methods to extend the service life of your Cone Crushers and improve overall production efficiency.

Core Maintenance Tips: 7 points

1. Be aware of the Crushing Limits of Your Cone Crusher

Every Cone Crusher has limits in its design that you will want to pay close attention to:

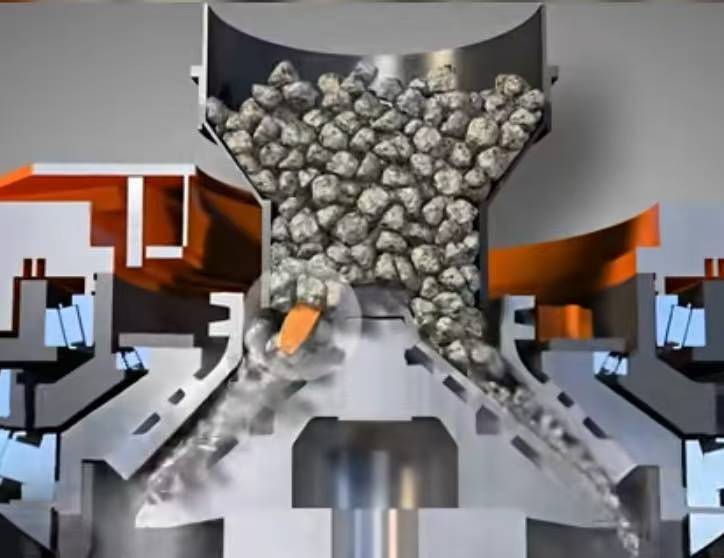

Crushing volume limit: There is a volume limit (this is set in the design), which limits the amount of material processed at one time. Overly large material can jam the mantle and damage the liners.

Power limit: Output power is limited to the rated motor power of the cone. Overloading the cone will run the motor at high amp draw which will contribute to excessive heat build up, burning out the motor, or worse, triggering protection shut down of the hydraulic system.

Application limits: Cone Crusher machines are usually designed for medium-hard to very hard materials. Soft or sticky materials will not only jam in the chamber, but can build up in the chamber and cause blockage.

Our Recommendations:

(1) Screen all materials per the design requirements, strictly abiding by the feed size criteria should not exceed the maximum feed opening of the crusher.

(2) Optimize developing operating parameters for the Cone Crusher, monitor the motor current for extended periods of time; look for overload operation.

(3) If the material you are processing has a high moisture content, is sticky, or behaves in a sticky manner; it is recommended to pre-dry partially before entering the hopper, or pre-screen for better material performance; or you will notice reduced output vs. quality of the material and terms of your crushing performance.

2. Uniform Feeding: The Key to Crushing Efficiency and Equipment Stability

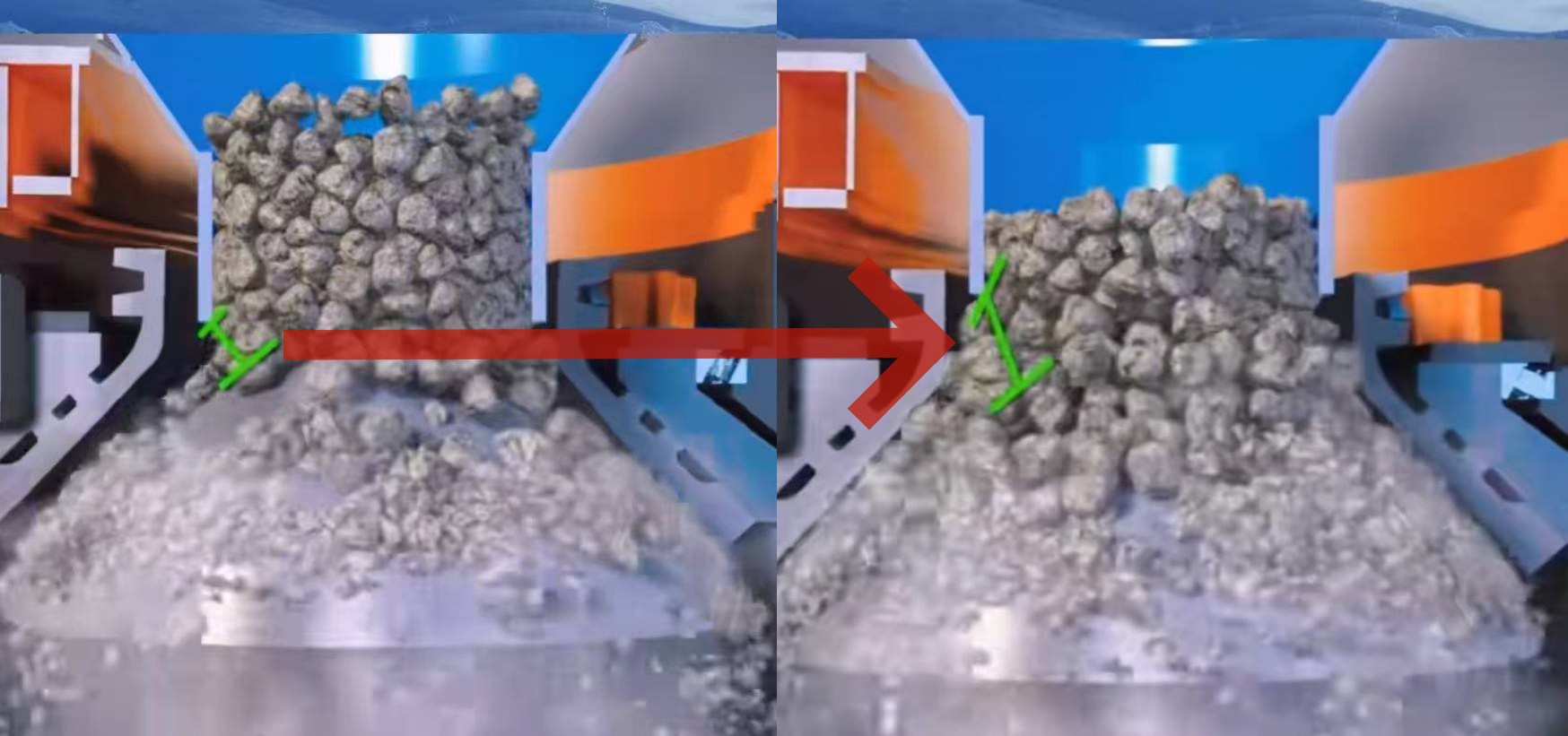

Uneven feeding leads to a host of challenges, including abnormal power fluctuation and enhanced energy consumption in the Cone Crusher machine; it also can cause periodic bearing overload, and non-uniform liner wear in the chamber ultimately leads to non-uniform product size and less capacity from the system.

To achieve uniform feeding, consider the following key measures:

(1) Filter the feed size to control oversize material from impacting the chamber directly.

(2) Utilize an automated feeding system, such as coordinating a vibrating feeder with a belt conveyor that maintains continuous and consistent material flow.

(3) Graduating material, avoid excessive fines to mitigate “over-crushing” in the chamber.

Tip: Screening equipment for pre-classification of material before it reaches the crushing stage is the best and most cost-effective approach to finding uniform and scientific feeding.

3. Adjust and Control the Cone Crusher Discharge Setting

The proper adjustment of the discharge setting is critical to achieving the correct balance between product size and equipment operating load. If the discharge setting is too large, the product will be too coarse for your process requirements. If the discharge setting is too small, it drastically increases the equipment load, and stable operation can become impossible.

How to adjust:

(1) Adjust based on the consistent wear condition of the liner.

(2) The best way to adjust is with a hydraulic adjustment system preferred, if possible, as it is more precise and much safer and faster than manual adjustment.

(3) Coned shape variety disposes of a very casualty and miss dimension tool adjustment that is periodically assessed for the correct discharge setting dimensions of your Cone Crusher, which are being too coarse or too fine, based on your process requirements.

4. Key Component Inspection and Replacement

(1) Maintenance of Liner and Bearing: Affects crushing efficiency and replacement costs.

Inspection Points:

Check the wear repeatedly and maintain a log of wear.

Check tightening nuts and “U” bolts to avoid loosening.

Recommendation: Replace once wear reaches the limit or cracks appear to avoid impacting product size.

(2) Cone Crusher Component to Check:

① Check all component connection bolts routinely.

② Check the drive belts to the Cone Crusher.

③ Check the electrical system of the Cone Crusher.

④ Check the safety protection devices of the crusher.

5. Managing the Lubrication System: Protecting Your Equipment’s “Circulatory System”

Not enough lubrication leads to an increase in friction, rise in temperature, galling of the components, and possible catastrophic situations in your Cone Crusher.

Main Steps:

(1)Use the proper lubricant oil specific to your model of the Cone Crusher equipment.

(2)Check the oil level, oil temperature, and oil quality regularly to ensure there is no water or contamination.

(3)Change the lubricant oil and filter regularly, and clean the oil basin.

(4)It is highly advisable to install an automatic lubrication monitoring system that will mechanically provide interlocked protection, based on oil pressure and oil temperature. For example, shut the Cone Crusher machine down automatically if oil pressure < 0.05 MPa or oil temperature > 55°C.

6. Maintenance of the Dust Protection and Seal System: The Initial Preventative Measure from “Internal Damage”

The dust seal system acts as the initial preventative measure that prevents external dust and sand, as well as other contaminants, from entering a Cone Crusher‘s transmission components (such as bearings). A failed defect will cause contamination of oily lubricants and abnormal wear to these components resulting in substantial “internal damage” to the equipment.

We recommend you: Regularly inspect the dust seal rings and fixing bolts; increase the inspection frequency when processing wet or damp materials.

7. Monitoring Operations: Making Way for Preventative Maintenance

The Cone Crusher’s key parameters (vibration, noise and current) have to be monitored continuously so that we can detect what is abnormal in a timely manner and to help prevent the occurrence of failures. Caution is also warranted with respect to long-term instabilities during the idling operations of the Cone Crusher to decrease energy waste and unnecessary wear of components.

Best practice: Monitor changes in vibration, noise and current to detect anomalies effectively and efficiently, and utilize intelligent monitoring systems for predictive maintenance.

Maintenance is More Than Just Maintaining, It’s an Investment!

The operating condition of your Cone Crusher has a direct impact on the efficiency and profitability of your entire production line. Systematic maintenance is not just a method of caring for your equipment – it is a strategic investment offering a long-term return.

Contact a Leading Cone Crusher Supplier

Sandreck is a professional manufacturer and source factory for crushers. With over twenty years of experience, we are able to provide you with precise and high-quality Cone Crusher and their wear-parts. Visit our website immediately to explore the full product range and obtain exclusive solutions.