With the vigorous development of the construction and infrastructure industries today, sand and gravel aggregates are essential basic raw materials. The sand making machine, the core equipment in sand production, silently undertakes the task of turning various kinds of ore and rock into qualified sand and gravel. The quality of the project and the efficiency of the construction are directly affected.

I. Sand Making Machine Definition and Role

As the name implies, Sand Making Machine is a crushing machinery specially designed for the production of manufactured sand equipment. Large-sized materials such as pebbles, granite, limestone and other mechanical effects will be crushed and ground into sand and gravel aggregates of different particle sizes.

In modern sand and gravel aggregate production process generally arranged in secondary crushing equipment after the sand making machine is the key link to determine the finished sand The final size, gradation and production capacity.

II. Classification by Structure

1) Vertical Shaft Impact Crusher (VSI Crusher)

Working Principle:

It adopts the “stone-on-stone” or “stone-on-iron” principle. The core is a high-speed rotating impeller that accelerates and throws the material out, causing it to collide and rub strongly with surrounding falling materials or the surrounding guard plate, thus achieving “self-crushing of the material” or precise impact crushing of the material.

Its advantages are as follows:

- The processed particles are cubic in shape with uniform particle size distribution;

- Suitable for construction industry sand;

- Fineness modulus is adjustable, and operation is simple;

- Operating stability is also quite good.

However, its disadvantages are:

The wear on wear-resistant parts (such as impellers and surrounding guard plates) is relatively fast, and the operating and maintenance costs are relatively high;

In terms of application,

Suitable for high-end commercial concrete, asphalt concrete, and high-grade highway surface materials production scenarios where the finished sand particle shape and quality requirements are stringent.

(2) Hammer Crusher

It adopts the “stone-on-stone” or “stone-on-iron” principle. The core component is a high-speed rotating impeller that accelerates and ejects material, causing it to collide and rub against surrounding falling materials or the shroud plates, thus achieving “self-crushing” or precise impact crushing.

Advantages:

High crushing rate, capable of crushing large particles into the required particle size.

Its compact structure and simple operation; it can handle large-particle materials without pre-crushing.

Limitations:

Hammer head wears quickly, especially when handling high-hardness materials; it easily clogs the grate bars when handling materials with high moisture content; the product particle shape is slightly inferior, with more powdery material.

Applications:

Primarily used for coarse and medium crushing of medium- to low-hardness brittle materials such as limestone and coal gangue, widely used in small and medium-sized stone quarries.

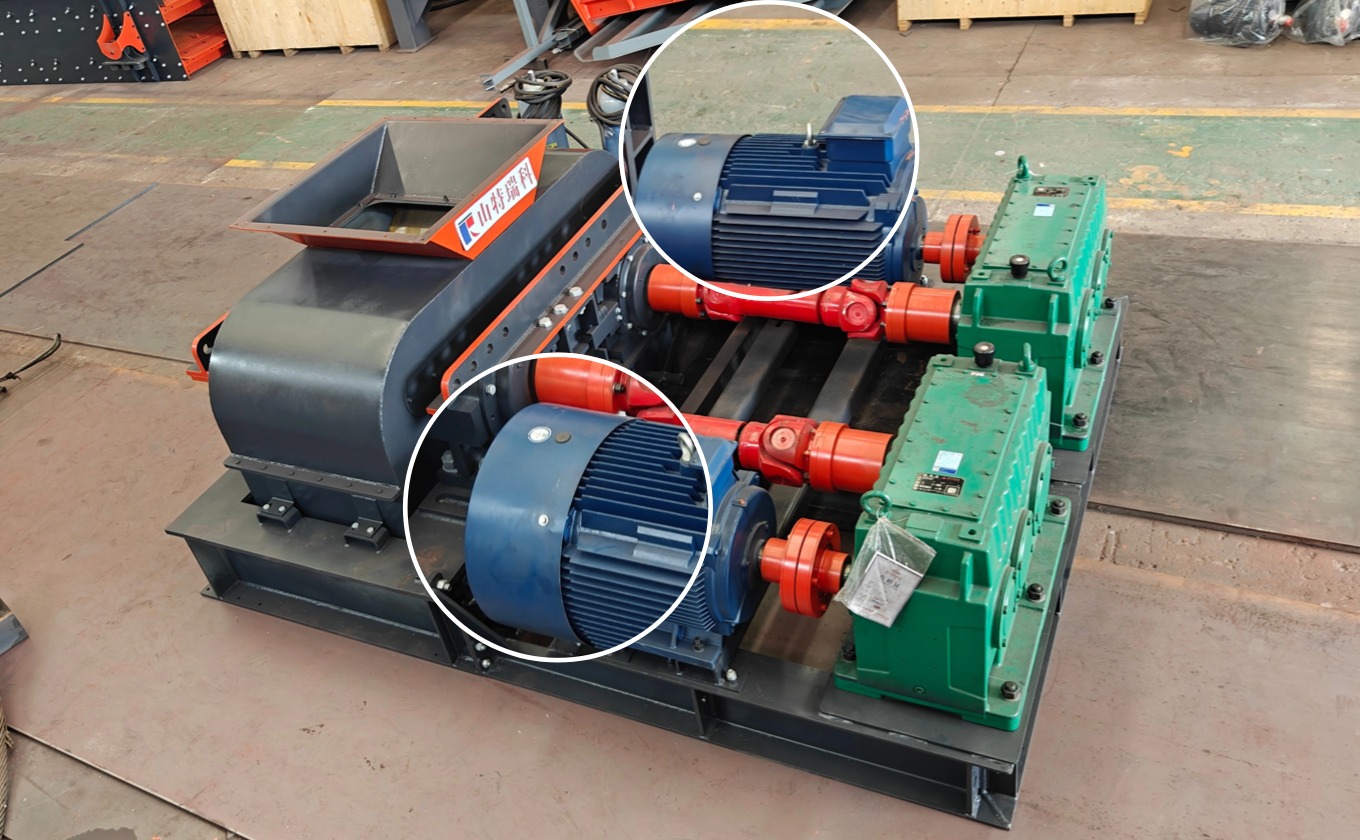

(3) Roller Sand Making Machine

The Roller Sand Making Machine adopts the working principle of double-roller extrusion. Two rollers rotate towards each other. When materials enter between the two rollers, they are gradually extruded and fractured, and finally crushed into the required particle size.

Advantages:

- Its advantages lie in low wear during operation and low frequency of wearing part replacement;

- The finished product has uniform particle size and stable gradation, without excessive dust generation;

- Furthermore, it has a simple structure, occupies a small area, and is convenient to maintain.

Limitations:

However, its production efficiency is relatively low. Due to the limitation of roller size, its production capacity is limited and cannot meet the needs of large-scale production.

Applications:

In terms of positioning, the Roller Crusher is suitable for the secondary and fine crushing of materials with hardness below medium level, such as the processing of gypsum and limestone. It is often used in small building material factories and chemical raw material crushing scenarios.

(4) CNC Sand Making Machine (Composite Crusher)

The CNC Sand Making Machine (Composite Crusher) combines the principles of Impact Crushers and counterattack Crushers. After materials enter the equipment, they first undergo preliminary impact crushing, and then collide and rub with hammers and lining plates multiple times in the crushing chamber to achieve full crushing. Additionally, the particle size of the finished product can be precisely controlled through the CNC system.

It has many advantages:

It is applicable to a wide range of materials, capable of processing both soft and medium-hard materials; it has a large crushing ratio and can directly crush large-sized materials into fine particle sizes; its energy consumption is relatively low, and the wearing parts are made of wear-resistant materials, ensuring a long service life.

Limitations:

However, in large-scale production, its capacity may not meet the demand, and its processing capacity has a certain gap compared with large-scale dedicated Sand Making Equipment.

Applications:

Its positioning is for the secondary and fine crushing as well as sand making operations of materials of various hardness levels, such as ore mining and construction waste recycling. It is particularly suitable for small and medium-sized production projects.

III. Classification by Mobility and Production Line Configuration

(1) Fixed Sand Making Machine

Fixed sand making production lines consist of equipment that is permanently installed to form a continuous production line. Their advantages include high output, stable operation, and low overall cost, but they require high initial civil engineering investment and are located in a fixed location. They are suitable for large-scale, long-term, and stable mines or building material bases.

(2) Mobile Sand Making Machine

Mobile Sand Making Machines integrate the sand making main unit, screening, feeding, and other equipment onto a mobile chassis, offering extremely high flexibility and allowing for rapid relocation without the need for a foundation. Their disadvantage is a higher investment per unit, making them suitable for projects requiring mobile production, such as construction waste treatment, scattered mineral resources, and short-term project.

IV. How to Select A Sand Making Machine

When you buy the Sand Making Equipment,

- The first thing to consider is how it is suitable for crushing materials such as size and moisture.

- Second, your production requirements direct you on the size of mill to keep in mind.

- In addition, finding out the crushing precision of different equipment according to the needed product size for course production.

- And you also need to consider the site conditions and your budget of investment.

- You can select a Sand Making Machine after understanding the factors which affect the Sand Making Machine.

V. Conclusion

We believe this article has helped you develop a systematic understanding, preparing you for subsequent investment decisions. Contact our technical team; we will design the most cost-effective sand making solution for your needs.