Gravity Separation Equipment

Gravity separation equipment efficiently separates materials based on density differences using natural forces.

![]() Operates with minimal power, reducing operational costs.

Operates with minimal power, reducing operational costs.

![]() Ideal for separating larger or denser particles like minerals.

Ideal for separating larger or denser particles like minerals.

![]() Robust design with fewer moving parts ensures easy upkeep.

Robust design with fewer moving parts ensures easy upkeep.

![]() Utilizes gravity and physical properties, avoiding chemical additives.

Utilizes gravity and physical properties, avoiding chemical additives.

Your Expert Gravity Separation Equipment Supplier in China

Sandreck is a professional mining machinery manufacturer. Our high quality Gravity Separation Equipment is one of the commonly used beneficiation equipment, which is sorted according to the principle of different material densities. It is widely used in the separation of metal and non-metallic ores, including gold, tungsten, tin, lead and zinc.

Sandreck’s Gravity Separation Equipment such as Shaking Tables, Jigs, Spiral Chutes, etc., can be applied to multi-stage separation needs such as coarse particle pre-throwing and fine particle recovery, achieving the dual goals of green environmental protection and efficient resource utilization.

Product By Features

Mineral separation equipment using particle motion differences in inclined flow.

Sandreck Gravity Separation Equipment Advantages

Sandreck Gravity Separation Equipment uses process intelligent gravity separation technology to control density stratification.

As a reliable source factory, Sandreck provides the customer mineral testing + customized separation solutions.

High manganese steel wear-resistant material + PLC intelligent control, improve service life and reduce maintenance costs.

Sandreck has 150+ service outlets, you only need one call, we will respond and send professional technician within 2 hours.

Source manufacturers, large-scale production factories, you can buy Gravity Separation Equipment at the lowest price.

Sandreck has a professional Gravity Separation Equipment production team, and can deliver within 20 working days after the contract is signed.

Why Choose Sandreck Gravity Separation Equipment?

Sandreck has been engaged in the research and development, manufacturing and sales of Gravity Separation Equipment for more than 20 years, serving more than 500 mines in more than 50 countries around the world.

We have rich experience in gravity separation of various ores. After several rounds of development, even with similar mineral processing results, we can provide you with solutions, accurately correspond to mine input data, determine your equipment grouping and combination.

What Materials Are This Equipment Mainly Used for?

Sandreck Gravity Separation Equipment is mainly used for the separation of metal ores such as tin, tungsten, gold, silver, iron, manganese, etc., using the density difference between useful minerals and gangue efficient separation.

Coal: separation of coal and gangue, improve the purity of coal; Non-metallic ores: such as quartz sand, remove impurities and light minerals to obtain high purity products.

Gold Mine Gravity Separation Process

This process follows a rational sequence of “preparation and waste treatment → fines concentration → purification → refining,” ensuring that every grain of gold is properly recovered.

Jig:Roughing and Waste Removal

Preparation and waste treatment: During preparation, the process adds coarse material (0.5-30 mm) and removes 70%-80% of the waste rock. This produces a highly concentrated coarse concentrate, significantly reducing the burden on subsequent stages.

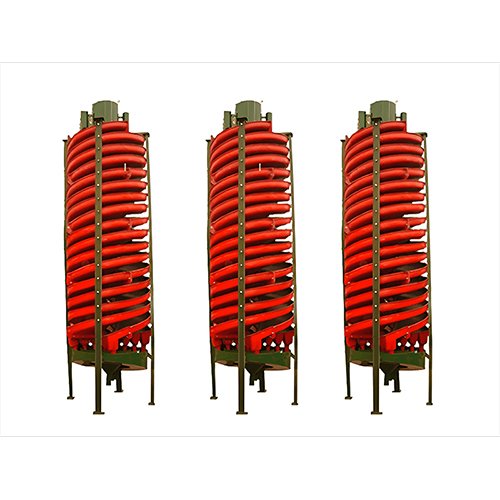

Spiral Chute: Fine Particle Concentration

This concentrates all fines (<0.5 mm)—preventing gold particles that the jig cannot capture. The gold content of fines reaches 15-30 g/t.

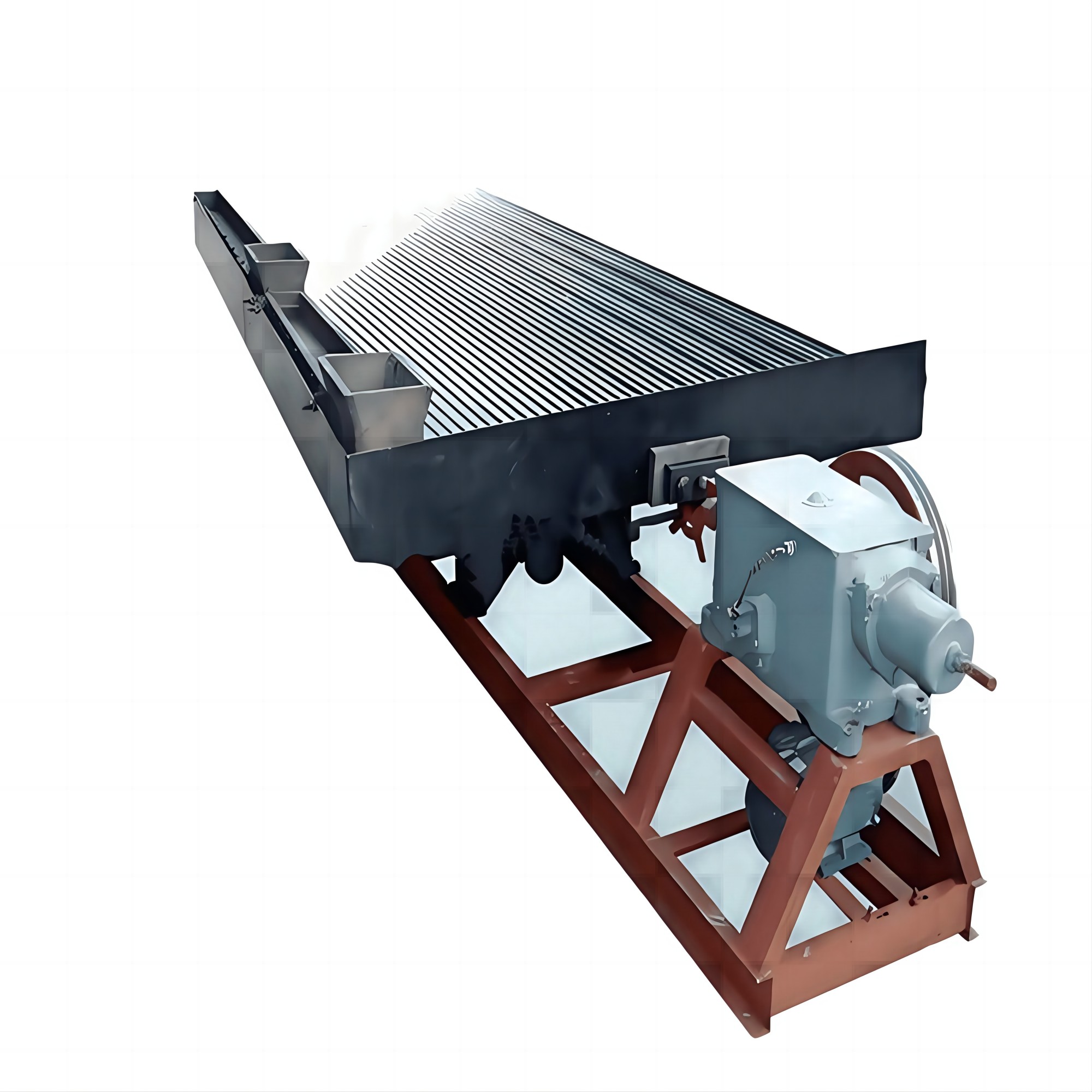

Shaking Table: Precision Purification

The shaker is the final separation process between the jig and the coarse gold concentrate from the spiral. Its ultra-high separation accuracy yields a marketable gold concentrate of 100-500 g/t.

Key Equipment For Gravity Separation Equipment

Grinding of raw ore to a suitable size for reclassification (0.01-5mm)

Classifies ore pulp by particle size, matching materials of corresponding particle sizes to the gravity separation equipment to avoid particle size mixing that affects separation accuracy.

Ore Dressing Centrifuge: Provides secondary recovery of fine minerals smaller than 0.074mm (such as fine gold and tungsten mud).

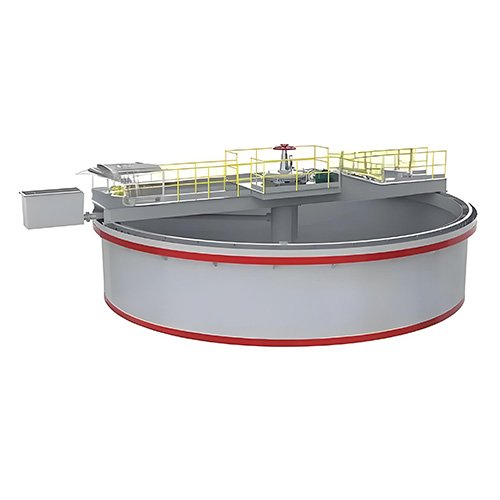

Thickeners (from 20% to 60%) and dehydrates (reducing the moisture content to below 15%) the concentrate pulp produced by gravity separation (such as gold and tungsten concentrates), facilitating subsequent smelting or transportation while reducing transportation costs.

Testimonials

Sandreck Gravity Separation Equipment mainly includes Shaking Tables, Jigs, and Spiral Chutes.

The results of Sandreck Gravity Separation Equipment are also closely related to the particle size, density, shape, release and specific gravity of the mineral. Other factors including water flow, slope, feed rate and slurry density also affect the separation process.

You must consider your ore properties, production needs and investment budget. After submitting your mine basic information, you will get Sandreck’s technical team’s purchase suggestions for your Gravity Separation Equipment within 24 hours.

Related Products

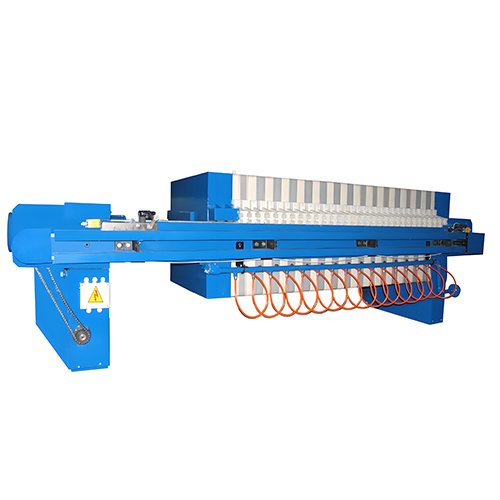

Press Filter is a commonly used separation equipment for solid liquid suspension

Sandreck filter presses are used as intermittent pressure filtration equipment