Have You Choosing the Right Jaw Plates for Your Jaw Crusher?

Jaw plates are the key parts of a jaw crusher. They just like “teeth” directly involved in crushing material.They could deeply impact crushing efficiency and the crusher’s lifespan.

This article will analyze the key points of selecting a jaw plate, in order to help you clarify your approach, making scientific decisions, and ensuring continuous production.

I. The Significant Meaning of Choosing the Right Jaw Plates

Choosing the right jaw plates is not just about replacing a part; it greatly affects your production efficiency:

- Matching material and tooth profile can significantly improve crushing efficiency, leading to higher output,

- More uniform product particle size and more regular particle shape, better meeting your requirements;

- Reduces production costs, decreases the frequency of jaw plate replacements, and avoids losses caused by downtime for maintenance.

II. Core Elements of Jaw Plate Selection

1. Choosing the Right Material is Key

(1) High Manganese Steel Jaw Plates

Advantages: Strong wear resistance, hardness further increases after processing.

Applicable to: Crushing high-impact materials like granite, basalt.

(2) Medium Manganese Steel Jaw Plates

Advantages: Stable hardening, minimal wear.

Applicable to: Medium and low hardness materials such as concrete, quartz.

(3)Medium-Carbon Low-Alloy Cast Steel Jaw Plates

Advantages: Balanced hardness and toughness, strong adaptability.

Applicable to: Medium and low hardness materials like limestone; performs better in small jaw crushers.

(4) High-Chromium Iron & High Manganese Steel Composite Jaw Plates

Advantages: Extremely high hardness and wear resistance, service life increased by 3-5 times.

Applicable to: Crushing high hardness materials like iron ore.

Limitations: Insufficient toughness, higher process requirements.

2. Must Match Your Jaw Crusher Types

The size of the jaw crusher determines the jaw plate dimensions and load-bearing capacity.

- If you use a large jaw crusher, choose high-strength, large-size jaw plates to withstand the impact of large materials.

- For small jaw crushers, standard strength jaw plates are sufficient, just meeting the crushing needs of small output, without extra cost.

3. Consider Material Characteristics

Material hardness is a core reference for selecting jaw plates. You can first test the material hardness, then choose:

| Hardness | Recommended Material | Advantages |

| Soft Material (Hardness < 5) | High Manganese Steel | Balances cost and durability |

| Medium Hard Material (Hardness 5-8) | Medium Manganese Steel | Balances hardness & toughness, stable material |

| Hard Material (Hardness > 8) | High-Chromium Iron | Ensures crushing effect, longer plate life |

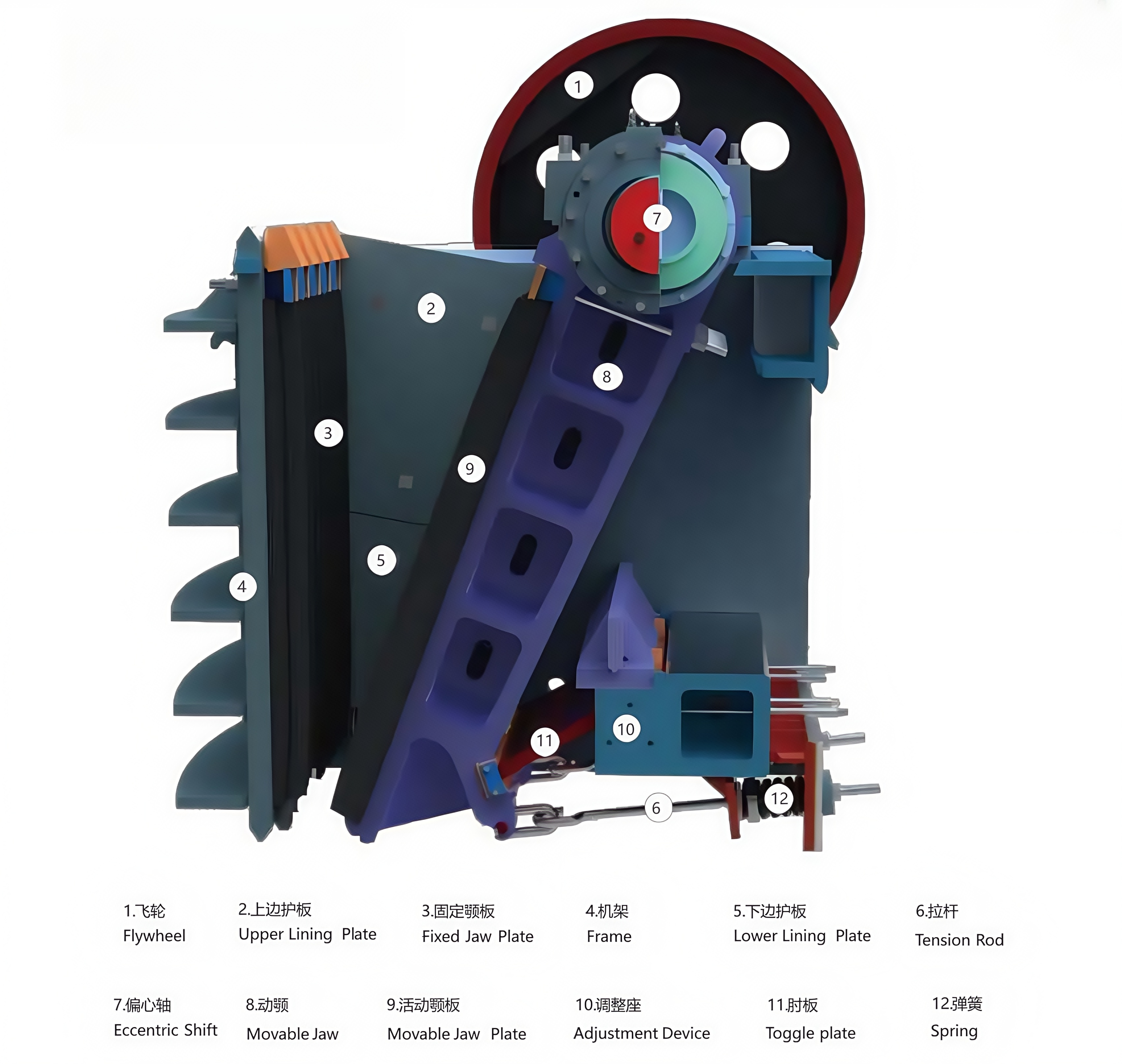

4. Distinguish Between Movable and Fixed Jaw Plates

During jaw crusher operation, the wear characteristics of the movable and fixed jaw plates differ, requiring differentiated material selection:

- Movable Jaw: Frequent stress, fast wear. It is recommended to choose a material with stronger toughness, such as high manganese steel.

- Fixed Jaw: Relatively stable stress. You can choose a slightly harder material based on the material, such as medium manganese steel.

5. Common Tooth Profile Classification:

(1) Tooth Profile Design: Choosing the Right “Tooth Type” for Your Jaw Crusher Plates

The tooth profile is the “front line” of the jaw plate in crushing. Choosing the right tooth profile directly enhances the crusher’s efficiency and product quality.

Coarse-tooth Jaw Plates: Large teeth, wide spacing. Suitable for the primary crushing stage of jaw crushers, they can quickly grip large materials and increase output.

- Fine-tooth Jaw Plates: Dense, short teeth. Used for medium and fine crushing, they ensure effective control of discharge size and guarantee uniform product.

- Wave-tooth Jaw Plates: Wave design, larger contact area, can reduce clogging of the crusher chamber by sticky materials.

(2) Core Strategy

When selecting jaw plates for your equipment – use coarse teeth for primary crushing, fine teeth for fine crushing, and wave teeth for sticky materials. For extremely hard materials, choose jaw plates with wear-resistant reinforced tooth tips.

III. Adaptation Solutions for Different Working Conditions

1.Large-scale Mining Operations (Processing capacity >1000 t/h, materials like iron ore, basalt)

Recommended Configuration: High manganese steel / Medium manganese steel large-size jaw plates (Movable jaw plate: High manganese steel, Fixed jaw plate: Medium manganese steel) + Coarse-tooth design;

Advantages: Impact resistant, wear resistant, capable of handling high-intensity crushing demands, ensuring continuous operation of the production line.

2. Small Construction Aggregate Production (Processing capacity <300 t/h, e.g., limestone, recycled concrete aggregate)

Recommended Configuration: Standard high manganese steel jaw plates (Both movable and fixed plates: High manganese steel) + Fine-tooth / Wave-tooth design;

Advantages: Economical and practical, meets aggregate size requirements, low maintenance cost.

3. Hard and Brittle Material Crushing(e.g., granite, pebble pre-processing for sand making)

Recommended Configuration: High-chromium iron fixed jaw plate + High manganese steel movable jaw plate + Coarse-tooth design;

Advantages: Fixed plate is wear-resistant, movable plate is impact-resistant, balancing crushing efficiency and service life.

IV. Brand and Manufacturing Process Considerations

When choosing Jaw Crusher Jaw Plates, we recommend:

- Don’t necessarily pursue the “most expensive”; the core is matching the working condition requirements, avoiding paying for excess performance, and ensuring the best cost-performance ratio.

- Prioritize meeting production needs, then compare cost-effectiveness: First clarify working conditions like material hardness and impact load, then select the material (e.g., high manganese steel, medium carbon steel), avoid blindly using high-priced materials.

- The casting process affects quality. Lost foam casting offers high surface precision and fewer defects. Heat treatment (e.g., water toughening) can improve wear resistance and structural uniformity.

- Finally, confirm if the jaw crusher supplier has quality certifications and test reports (e.g., CMA/CNAS), ensuring material composition, hardness, and other indicators meet standards, reducing risks in your subsequent use.

V. Avoiding Common Misconceptions

1.Misconception: Only looking at price, choosing low-price, inferior quality jaw plates.

Solution: You should prioritize looking at material and suitability. Low-pricejaw plates wear easily and need frequent replacement, actually increasing overall cost.

2.Misconception: Ignoring material characteristics, blindly selecting material.

Solution: First test the hardness of the material you need to crush, then select the corresponding adapted jaw plate, avoid “using soft plates for hard material” or “using hard plates for soft material,” which affects production efficiency.

VI. Case Study: Influence Derived from the Selection of the Proper Jaw Plates.

Case 1. Large Iron Ore Mine (Medium Hard Material).

Difficulty: PEV950 ×1250 jaw crusher used for the treatment of iron ore (hardness 7-8). High manganese steel jaw plates used and their wear was very heavy, displacing them once in 20 days. An unsuitable stoppages arose and an unsatisfactory grading of the product.

Solution: Use of “High Toughness Medium Manganese Steel Movable Jaw Plate + Standard Medium Manganese Steel Fixed Jaw Plate + Coarse Teeth”.

Results: The life of the jaws was increased to about 60 days, number of annual stoppages reduced by 48 hours. The output was then increased from 500 t. per hour to 600 t. per hour, and the amount received from the increased output was over 100.000 dollars per annum.

Case 2. Small Construction Aggregate Plant (Soft Material).

Difficulty: The PEV600 ×900 crusher was used for the treatment of limestone (hardness 3-4). The jaws of high chromium iron was chosen and it broke about once in fifteen days, powder content 20% (not up to standard). The consumption of electric energy was 15% greater than necessary.

Solution: High manganese steel jaws + fine tooth design (spaced teeth 45mm, reduced to 30 mm).

Results: No breakage of jaws, their life of 45 days attained. The powder content of the crushed material = 8% (up to standard). The electric current consumption was reduced by 12% and the saving effected was equal to 10,000 dollars per annum.

VII. Choosing the Right Jaw Plates Means Choosing the Right Benefits

Choosing the right jaw plates is not just about selecting an equipment part; it is a highly efficient, stable, and sustainable production method.

[Sandreck], as a professional jaw crusher manufacturer deeply involved in China’s mining machinery field for many years, we sell jaw plates of different materials and other jaw crusher accessories. If you have needs, feel free to contact us.