Limonite is a weakly magnetic iron ore resource widely distributed in the earth’s crust, with reserves second only to hematite and magnetite. It is capable of providing high quality iron ore resources for the iron and steel industry after processing and has important industrial value.

Although limonite is easy to mine, it has high water content, fluctuating grade and weak magnetic properties. If you use an unsuitable beneficiation process, the iron ore extraction rate will not only be low, but your comprehensive cost will also be high. How to solve these difficulties and maximize the use of your iron ore resources? This article will provide you with some ideas.

I. Overview of Limonite

Composition: limonite ore contains 35%-55% iron. The original stone contains a variety of minerals (such as acicular ferrite, fibrous ferrite, silica and clay), the composition is complex, extraction is difficult.

Characteristics: the ore is loose and porous, easy to sludge in water, unstable physical properties, not conducive to sorting; the ore magnetism is very weak, the extraction rate of conventional magnetic separation is low; the fluctuation of the grade of the ore, it is difficult to choose the appropriate beneficiation process.

Place of origin: China, Russia, the United States, Australia, Brazil, India and other places have large limonite deposits distribution.

Uses: Limonite after processing and extraction: ① can be directly smelted and smelting can also be used as metallurgical additives to reduce your production costs; ② can be extracted from the iron powder or the preparation of magnetic materials, used in the production of pigments and magnetic products; ③ is an important raw material for the manufacture of abrasives and refractory materials; ④ can be used in agriculture, to improve the soil structure.

Ⅱ.How to Extract Limonite

Due to the low grade and complex composition of iron ore, the use of combined beneficiation method can greatly improve the recovery rate of limonite. The following are the specific operation steps:

Step 1: Pre-treatment of impurities

Limonite is mostly produced in swamps and wetlands, the ore contains more water, mud and other impurities, and the cost is very high if it is directly treated. Pretreatment to remove impurities can increase your recovery rate.

·Natural drying: limonite is easy to be muddied when it meets water, drying in the mine can reduce its water content and facilitate the subsequent processing.

·Pre-screening: Use vibrating screens to remove large chunks of veinstone and impurities, reducing ineffective ore processing.

·Dewatering: use a drum dryer to control the moisture of limonite below 12%.

You can use a vibrating screen with hydrocyclone to treat heavily muddied materials to reduce the loss of valuable minerals.

Step 2: Crushing limonite

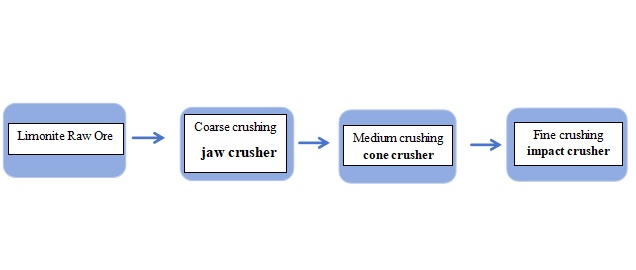

Although limonite has a loose structure, it is tough. Crushing limonite can refine the pre-treated ore, ensure the uniformity of ore particle size, and improve the efficiency of subsequent processing. Three-stage closed circuit crushing can get the particle size you want.

Coarse crushing: The pre-treated limonite ore is fed into the jaw crusher by vibrating screen to be crushed to 10-15cm to realize the preliminary crushing.

Medium crushing: Use cone crusher to further crush to 2-5cm.

Fine crushing: Use an impact crusher to crush to 5-15mm. Finally, screen out the required particles through screening equipment, and the unqualified particles are sent back to be crushed again. If you have higher requirements on the quality and powder content of the finished product, the double roller crusher can meet your needs.

Step 3: Magnetization Roasting

Among many mineral processing processes, magnetization roasting followed by magnetic separation can effectively process low grade and complex composition limonite. This is also the core step of limonite processing. It can strengthen the magnetism of limonite in this process and create conditions for the magnetic separation link.

The crushed material is fed into the rotary kiln, a reducing agent (anthracite) is added and an appropriate amount of air is introduced. At this time, limonite will be reduced to magnetite and the water content will be reduced. After roasting, the material is ventilated and cooled to room temperature to avoid combining with carbon dioxide in the air and weakening the magnetic properties.

Rotary kiln roasting can be adapted to the needs of most mineral processing plants, but you need to pay attention to your reductant dosage, roasting temperature and time. We recommend a reductant dosage of 3%-5% of the original ore mass and a roasting temperature of 800-850°C for 60-90 minutes.

Step 4: Grinding

Grinding the roasted limonite with a ball mill enables the iron ore particles to fully dissociate and release more magnetically separable iron minerals.

The ball mill lining is made of wear resistant material with low maintenance cost. You can choose different sizes of steel balls according to the required product size, the finer the size, the higher the magnetic separation recovery rate. However, you also need to pay attention to controlling the grinding time and the rotating speed of the equipment to avoid increasing energy consumption and destroying valuable minerals.

After grinding the mineral powder can be used to sieve the coarse particles out of the sieve machine, grinding again.

Step 5: Magnetic Separation

The iron minerals you get from magnetic separator are closely related to your final benefit. You can get an iron ore concentrate with a grade of 62.94% in the magnetic separation process. If the grade of primary magnetic separation is lower than 60%, you need to upgrade the magnetic field strength for secondary magnetic separation. The magnetic separation tailings can be used for brick making, mine backfill and other projects after dewatering to maximize the use of resources.

Note: Each ore deposit has its own specificity, before you determine the final beneficiation program, we suggest that you can carry out the beneficiation process flow test to ensure the beneficiation science. Of course, this will also affect your profit.

Ⅲ.Case Sharing

Case 1: Yunnan small-scale limonite mine (daily processing capacity of 500 tons) processing case

Working condition: the original ore limonite Fe₂O₃ content of 42%, the impurities are mainly clay, quartz, mud phenomenon is serious, initially processed by conventional technology, the grade of iron ore concentrate is only 55%, the recovery rate is less than 60%.

Optimization: add high-frequency vibrating screen to desliming in pre-treatment stage, and choose jaw + cone crusher combination in crushing link.

Result: Iron ore concentrate grade increased to 62%, energy consumption of tons of ore reduced by 18%. The recycling rate of wastewater reaches 90%, which effectively solves the problems of easy sludging of raw ore and low iron extraction rate.

Case 2: Australia symbiotic limonite mine (accompanied by hematite, daily processing capacity of 800 tons) processing case

Working condition: limonite and hematite symbiosis, the original ore Fe₂O₃ content of 38%, the magnetism is weaker, the processing is more difficult.

Optimization: adjust the amount of reductant to 4.5% of the original ore quality in the magnetization roasting stage, extend the roasting time to 1.5 hours, and add a selection operation in the magnetic separation stage.

Result: The final iron ore concentrate grade reaches 63.5%, recovery rate 75%. Compared with the original process, the grade was increased by 8 percentage points and the recovery rate by 12%. The tailings are treated and used to fill the mining area, realizing environmental compliance and efficient resource utilization, which meets the requirements of local environmental protection policy.

Conclusion

There are many difficulties in limonite processing, but combining the ore characteristics and parameters, choosing the right process and equipment, you can almost realize the double improvement of iron grade and recovery rate.

As a professional mining machinery and equipment supplier, we not only provide equipment, but also provide technical support for the whole process of mineral processing. If your mine has the same problem, feel free to contact Sandreck.

FAQs

Q:What exactly is limonite?

A:Limonite is a watery iron oxide mineral, which is not a single mineral but a mixture of several minerals. It is not a single mineral, but a mixture of several minerals. It is usually brown, yellow or black in color, with high water content, and is one of the important iron ore resources.

Q:What is the main difficulty in treating limonite?

A:The core difficulty lies in its characteristics of “high water, low grade and weak magnetism”. The low grade and complex composition lead to low smelting efficiency; it must be pre-treated by roasting and other pre-treatments to turn it into a strong magnetic mineral, which increases the technical difficulty and cost.

Q:What are the environmental challenges of processing limonite?

A: The main challenges include the potential generation of exhaust gases (SO₂) from the roasting process; the storage and disposal of tailings; and water consumption and wastewater reuse in the beneficiation process. Modern projects must be accompanied by efficient facilities for dust removal, desulfurization and dry discharge or comprehensive utilization of tailings.