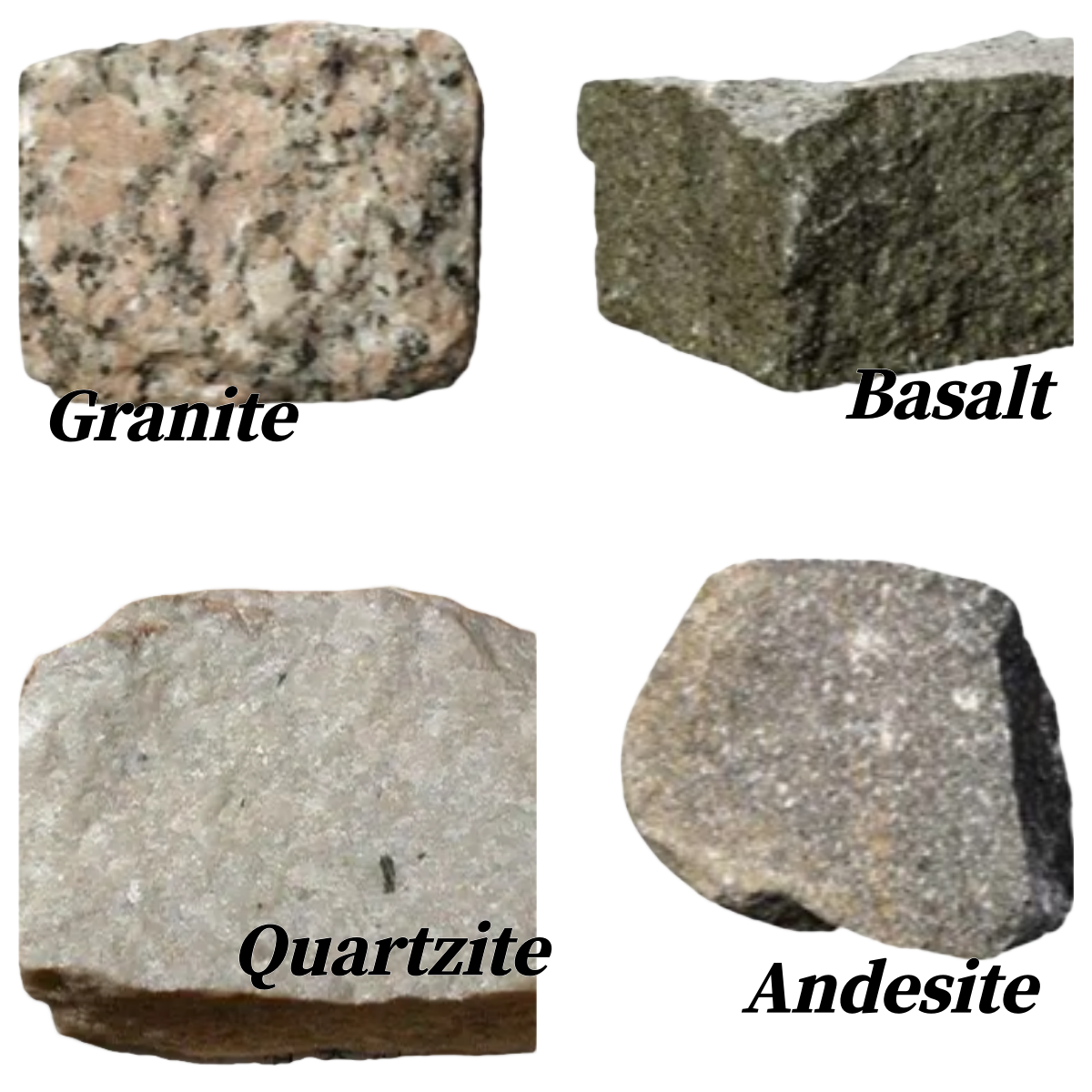

For the processing of hard rocks such as granite, basalt, quartzite, and corrosive materials, there have been far too many cases where crushing plant owners experienced insufficient capacity, rapid wear, and high costs due to improper equipment selection. Today, let’s discuss practical considerations regarding equipment selection for hard rock crushing plants.

Ⅰ. Mature Solution for Hard Rock Crushing: Jaw Crusher + Cone Crusher

Years of industry practice have proven that the standard, mature solution for hard rock crushing plants is the golden combination of “Jaw Crusher + Cone Crusher”.

Jaw Crusher – Primary Crushing

The jaw crusher is a primary crushing device specifically designed for hard rock. It is the first gateway of your crushing process, and its reliability directly affects the smooth operation of your entire production line.

When selecting a machine, you need to consider the following factors:

Robust Frame:Choose a jaw crusher with a frame made of thickened steel plates. Even under harsh working conditions, this prevents frame deformation or cracking, ensuring long-term stable operation of your production line.

Sturdy and Durable:Please pay attention to whether wear parts like the jaw plates and cheek plates are made of high manganese steel. This material can withstand the impact of large feed material, extending the life of wear parts and saving you maintenance costs.

High Reduction Ratio:The deep crushing cavity design allows for direct crushing of large raw stones up to ≤1500mm in size. No pre-processing is needed, saving you initial investment and time.

Easy Adjustment: We recommend choosing a jaw crusher with a hydraulic wedge adjustment system. This allows you to adjust the discharge opening size (to any target size between 5mm and 40mm) either during operation or while stopped, significantly reducing downtime.

Cone Crusher: – Secondary/Fine Crushing

The cone crusher serves as the secondary crushing equipment (for intermediate and fine crushing) in hard rock processing. It utilizes the “inter-particle crushing” principle, working through compression and impact between material particles. This significantly reduces wear on the consumable parts, saving you operating costs.

When choosing a cone crusher, be sure to consider the following points:

Wide Application Range:Choose a cone crusher where you can switch between intermediate and fine crushing chamber types simply by replacing the liners. This meets your various crushing needs.

Excellent Product Shape:Choose a cone crusher that produces cubic-shaped end products with low flakiness content. This allows you to meet the material requirements for high-standard sand and aggregate without needing to add a VSI crusher (shaping machine).

Overload Protection System:Choose a cone crusher equipped with an overload protection system. This way, when oversized pieces or non-crushable foreign objects (like iron pieces) enter the crushing chamber, it can automatically discharge the object and reset without requiring manual clearing, ensuring your production continues uninterrupted.

Sturdy and Durable:Verify that its core wear-resistant parts (such as the mantle, concave, liners, etc.) are made of special alloy steel. This material can improve wear resistance by 30-50%.

Ⅱ.Hard Rock Crushing is a System Engineering Project, Not Achievable by a Single Machine

A well-functioning hard rock crushing plant is not accomplished by one machine alone. It requires precise matching across all stages from “feeding — crushing — screening — conveying.”

We have outlined the key points for supporting equipment for you:

Feeder:Choose a grizzly feeder (bar feeder). It provides uniform, stable feeding into the jaw crusher while simultaneously screening out fines and impurities. This is the first step in creating stable conditions for subsequent crushing.

Vibrating Screen:When selecting, consider the material characteristics and final product requirements to match the corresponding model and screen mesh material, ensuring your precise screening needs are met.

Belt Conveyor:Connects all stages of the hard rock crushing plant, transporting the material.

VSI Crusher (Sand Making Machine):If you have a demand for high-quality manufactured sand, you will need to choose a VSI crusher.

Ⅲ.Hard Rock Crushing Solutions

Based on project requirements, we have outlined the following classic configuration schemes:

1.80-120 Tons/Hour – Small Hard Rock Crushing Plant

Applicable Scenarios:Small-scale mines and quarry projects, small infrastructure projects, tailings recovery, etc.

Recommended Configuration:

Feeder: GZD9638 Feeder

Primary Crushing: PEV600×900 Jaw Crusher

Secondary Crushing: HST100 Single-Cylinder Hydraulic Cone Crusher

Vibrating Screen: YZS1500 Vibrating Screen

Benefits for You:We recommend using the HPT300 multi-cylinder cone crusher because, compared to single-cylinder models, it offers higher wear resistance and stability.

This scheme offers high applicability, low failure rates, and stable operation. It can handle continuous 24-hour operation with no issues.

2.120–300 Tons/Hour – Medium Capacity for Highly Abrasive Rock

Applicable Scenarios:Medium-sized sand and aggregate plants. If your raw material is highly abrasive rock like basalt or diabase, and the project is for a medium-sized sand/aggregate plant or highway/railway infrastructure projects.

We Recommend:

Feeder: GZD5200 Feeder

Primary Crushing: PEV900×1200 Jaw Crusher

Secondary Crushing: HPT300 Multi-Cylinder Hydraulic Cone Crusher

Vibrating Screen: YZS2160 Vibrating Screen

Benefits for You:We recommend using the HPT300 multi-cylinder cone crusher because, compared to single-cylinder models, it offers higher wear resistance and stability.

This scheme offers high applicability, low failure rates, and stable operation. It can handle continuous 24-hour operation with no issues.

3.Large-Scale Multi-Product Hard Rock Crushing (300–500 Tons/Hour)

Applicable Scenarios:If your goal is to build a large-scale sand and aggregate base, needing to produce multiple aggregate specifications and high-quality manufactured sand simultaneously for sale in high-end markets.

We Recommend:

Feeder: GZD1352 Feeder

Primary Crushing: PEV1200×1500 Jaw Crusher for primary crushing

Secondary Crushing: HPT500 Hydraulic Cone Crusher for secondary crushing

Tertiary Crushing (Sand Making): VSI1150 Crusher for shaping and sand making

Vibrating Screen: YZS3075 Multi-layer Vibrating Screen

Benefits for You:This scheme combines crushing and screening. It produces high-quality crushed stone and premium manufactured sand, fully meeting the highest material requirements for construction aggregates and concrete batching plants, giving you significant market competitiveness.

4.Mobile Crusher Scenarios

Applicable Scenarios:If your project sites are scattered, have short cycles (e.g., road construction projects, construction waste processing), or require frequent relocation within a mining area.

We Recommend:Flexibly combine tire-mounted or track-mounted mobile jaw crushing stations, mobile cone crushing stations, and mobile screening stations according to your specific needs.

Benefits for You:The modular mobile station design allows for rapid deployment, moving the production line right next to the raw material. Installation can be completed within 30 minutes, putting it into production quickly. This can significantly reduce your material transportation costs, greatly improving economic efficiency.

IV. Choosing Partners Requires Caution

When selecting a partner for your hard rock crushing needs, do not focus solely on price. Instead, evaluate whether they can provide full lifecycle services for your equipment.

- Whether they possess a mining machinery production license and if all the equipment they sell has passed ISO quality system certification.

- Whether they have the capability to provide customized solutions.

- Whether they have experience with similar hard rock crushing projects.

- Whether wear parts are made of highly wear-resistant materials and if the entire hard rock crushing system is highly automated.

- Whether they can offer 24/7 technical services covering planning, installation, and operation.

- Whether spare parts are readily available and can be delivered promptly.

If you are currently selecting equipment for your hard rock crushing plant, we hope this article is helpful. If you have any further questions, please contact us. Our technical team will provide you with one-on-one customized service.