In mineral processing, ceramics, chemical industry, new materials and many other industries, Ball Mill is the core equipment of material crushing and mixing. However, the grinding medium is the real main character that decides grinding efficiency, product quality and operation cost.

This article will systematically outline the key factors in selecting grinding media to help you make the best decision.

Ⅰ. The Key Role of Grinding Media in a Ball Mill

The grinding media in the Ball Mill process has two core functions: impact crushing and grinding stripping. The selection of grinding media directly determines:

1.Grinding efficiency of the Ball Mill: affects the time and energy consumption to reach the target fineness.

2.Product quality: Media abrasion may contaminate the product, affecting its purity, whiteness, or chemical properties.

3.Operating costs include the wear and tear of the medium, electricity consumption, and equipment maintenance.

Therefore, selecting grinding media is not merely about ‘purchasing steel balls’; it requires you to make a technical decision that balances material properties, process objectives, and cost-effectiveness.

Ⅱ Key Factors in the Selection of Grinding Media

1.Basic Information

Before making any selections of a Ball Mill, it is vital to understand the following important parameters of the grinding media:

(1) Material properties:

①Density–High-density media (like steel balls) provide strong impact force, making them suitable for coarse grinding and hard materials.

②Hardness–The harder the media the less they are subject to wear and the longer practically they will last.

③ Wear resistance–Quickly wearing media not only tend to contaminate the product but involve a considerable extra cost in replacing them.

④Chemical composition–This should if possible be such as to avoid reaction of media with material.

(2)Physical specifications:

①Size–Large media (say over Φ60 mm.) fall with a heavier blow and are, therefore, useful for poundings and crushing work upon coarse pieces. Small balls (perhaps Φ10 to Φ20 mm.) offer more points of contact and are better for fine grinding.

②Shape—Usually either spherical or short cylindrical (in other words, rodlike) in form.

2. Clarifying “What to grind” — Fundamental properties of the material determine the properties of the medium.

Key point: The “character” of the material governs the “category” of the medium.

(1) Start with hardness & brittleness-using Moh’s hardness or the work index for a quick concept (quartz sand is Moh’s 7, calcite is Moh’s 3).

(2) Chemical properties and contamination requirements: The grinding medium may wear during use and disintegrate tiny amounts of itself into the product.

3. “What to use for grinding” based on performance and cost.

Core Insight: There is no single best medium; only trade-offs of performance and cost.

Some key performance characteristics at a glance

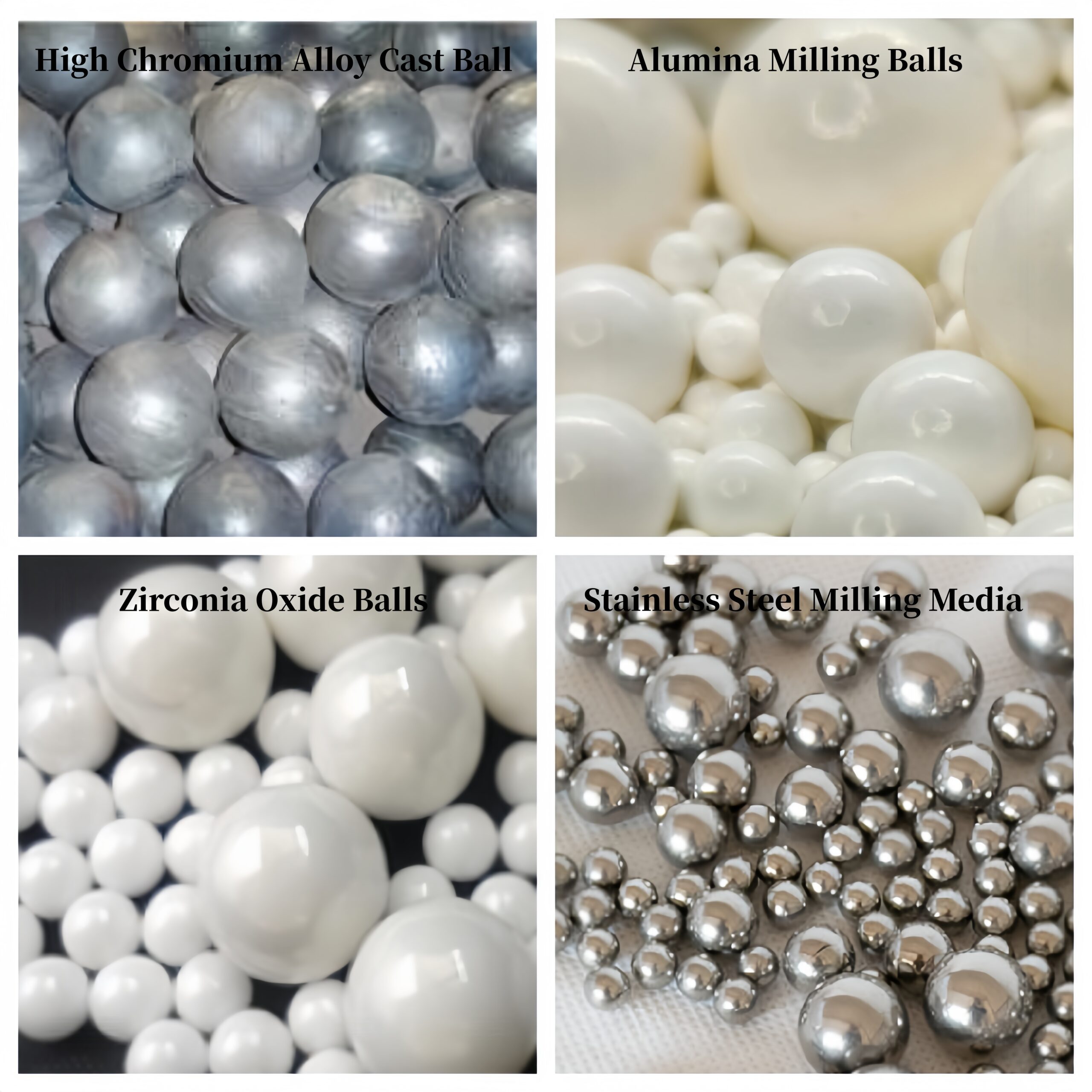

| Material Type | Core Characteristics | Weaknesses | Typical uses |

| High Chromium Alloy Cast Ball | Impact resistant, extremely good wear properties and cost effective. | Possible contamination with iron. | Coarse and fine grinding of metal mines and grinding of cement clinker |

| Alumina Milling Balls | Completely metal free, corrosion resistant and very hard. | Somewhat brittle. | Wet Grinding of Ceramic Glaze, Non-metallics Minerals and Electronic Materials |

| Zirconia Oxide Balls | Heavy density (in other words approach that of a steel ball), very nice anti wear properties, zero pollution. | The price is very high.

| The ultrafine wet grinding of lithium battery materials, the high-end of territory pigments and pharmaceuticals. |

| Stainless Steel Milling Media | Exquisite corruption resistance effect, really sanitary safe. | Ability to resist wear is fair and costliness. | Food, medicine, & Chemical corruption protection. |

4.Clarifying the “How Fine to Grind” -Core Parameters Determined by Process Objectives

Core Concept: Target granularity serves as your “compass” for selecting media size.

(1)The quantitative relationship between fineness requirements and medium size

The golden rule: “Use a large ball for coarse grinding, and a small ball for fine grinding.”

Quick reference table:

| Process stage | Target product: | Recommended range of medium sizes | Primary function |

| Crush / First-stage Mill | > 0.5 mm | Φ50 – 100 mm | Impact grinding |

| Fine grinding / Second-stage grinding | 0.074 – 0.5 mm | Φ20 – 40 mm | Impact and grinding combined |

| Ultrafine grinding | < 0.074 mm | Φ3 – 15 mm | grinding and removing the material. |

(2)Dry Process and Wet Process: Fundamental Differences in Kind of Process.

- Wet grinding in Ball Mills is usually the more efficient and the better for dispersing heat.

Medium Density must be more than that of the slurry. Otherwise effective sedimentation and grinding are impossible.

- Dry grinding of Ball Mill where it is difficult to get rid of heat, and where “milling” or adhesion of materials easily occurs.

Medium Density: It is necessary to have a less rapidly wearing medium in dry grinding, on account on account of the more direct friction between the medium and the materials, and between the medium and the liner.

5. Clarify “How to Mix” -The Soul of Efficiency of Grading and Filling

Core Insight: To maximize your Ball Mill‘s performance, it requires a scientifically optimized combination of components.

(1)Optimization of grinding media gradation

Large balls crush larger particles, medium balls serve as a bridge, and small balls fill the gaps. If there are too many gaps between the balls, the small particles won’t be ground sufficiently.

Initial gradation attempts can be made according to the volume ratio of large:medium:small = 4:3:3 or 3:4:3.

(2)The optimal filling range for Ball Mills (25%-45%)

Listen to the sound: if the sound is empty, it may be underfilled; if the sound is muffled, it may be overfilled.

Material inspection: Perform scheduled shutdowns for inspection. Overfilling may indicate material accumulation at the discharge end.

Ⅲ. Case Study on the Selection of Grinding Media

Case 1: Coarse grinding of metal mines (iron ore)

Requirements: Material Mohs hardness: 6.5–7 (hard), target particle size >0.5mm (30 mesh), no iron contamination restrictions.

Solution: High-chromium alloy cast balls (high impact + high wear resistance + high cost-effectiveness), Φ60–100mm (graded 4:3:3), filling rate 38%–42%.

Case 2: Non-Metallic Ore Fine Grinding (Calcite)

Requirements: Material Mohs hardness: 3 (soft), target particle size 0.1–0.3mm (50–150 mesh), iron-free contamination required.

Solution: Alumina ceramic balls (zero metal contamination + corrosion-resistant), Φ20–40mm (graded 3:4:3), filling rate 32%–35%.

Case 3: Ceramic Glaze Wet Grinding

Requirements: Material contains acidic components, target particle size <0.074mm (200 mesh), sensitive to iron impurities.

Solution: Alumina ceramic balls (zero iron contamination + high hardness), Φ8–15mm (graded 3:4:3), filling rate 33%–38%.

Ⅳ.Conclusion

The secret to choosing the correct grinding media for your Ball Mill, comes down to being well acquainted with your material & process and scientifically matching the material type and specs of your grinding media accordingly.

We hope this article is useful. If you have any questions, Sandreck is here for you – use our website or customer service hotline to get custom grinding media selection solutions for your Ball Mill.

Let us help you find the right match for your Ball Mill warehouse.