1. Introduction

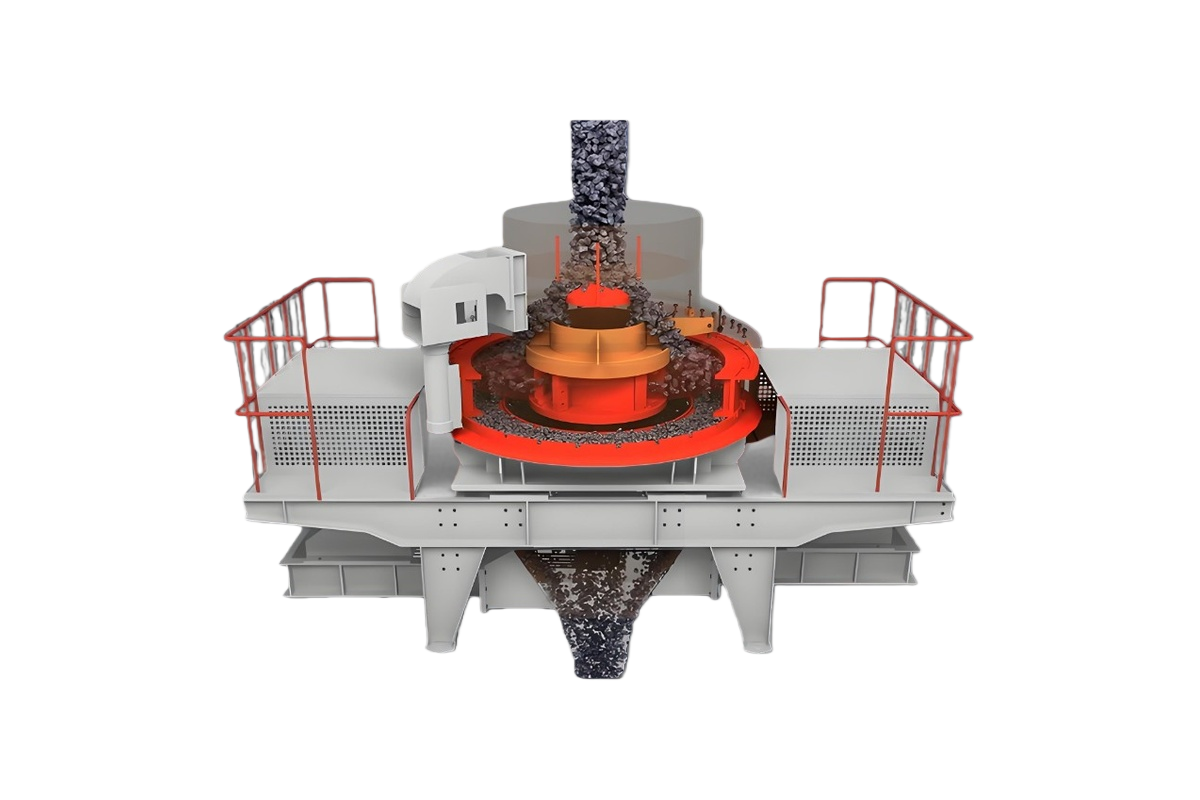

The letters “VSI” are short for vertical shaft impact; this is an Impact Crusher with a vertical shaft that rotates around its own axis to deliver material to it by applying force.

But what is the VSI Crusher working process? You may be interested. This guide will help you to have a deeper understanding of VSI Crusher.

2. VSI Crusher Parts

To get to know how a VSI Crusher Machine works inside, it is helpful to make yourself familiar with each of the major parts of a VSI and what they do during the “sling and shatter” process.

VSI Crusher Feeding Hopper

The Feed Hopper is where raw material first gets to “hug” the VSI Crusher, this vital item should permit the raw feed to flow freely into the Crusher with no restriction or blockage.

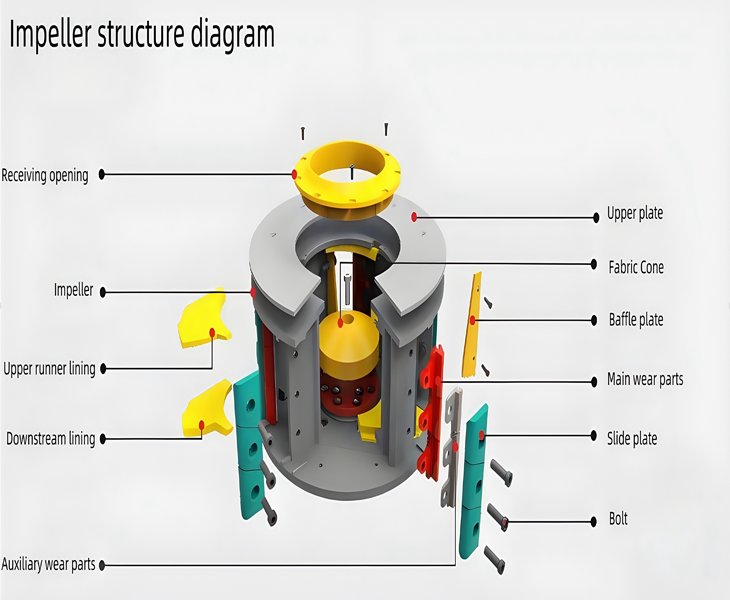

VSI Crusher Rotor

The main component of a VSI Crusher. It’s a fast-spinning steel impeller, which spins faster than 60-80m per sec- over 280 km/h if you like it that way!

VSI Crusher Impact Tips

The wear resistant “teeth” of the Rotor, located at the ends. As the Rotor spins they fling material away from the Rotor in a particular directions.

VSI Crusher Feed Tube / Cascade Tube

This is a specially designed channel which brings the material in from the Feed Hopper and feeds it into the center of the rotor perpendicular to its axis.

VSI Crusher Rotor Guide Table

This is either a fixed or rotating guide which helps to distribute material evenly over the rotor impeller itself.

VSI Crusher Crushing Chamber & Lid

The VSI Crusher lid on the chamber retains all the impact forces that are made within the chamber flooring and governs the material ejecting the chamber.

VSI Crusher Motor & Drive System

The Motor & Drive System of the Electric Series The source of energy is usually an electric motor of sufficient size.

3. Two Basic VSI Crusher Crushing Principles

What is unique about the VSI Machine is that it can be operated in either a rock-on-rock or a rock-on-steel mode.

Knowing which to select for your application will enhance product quality and keep costs down.

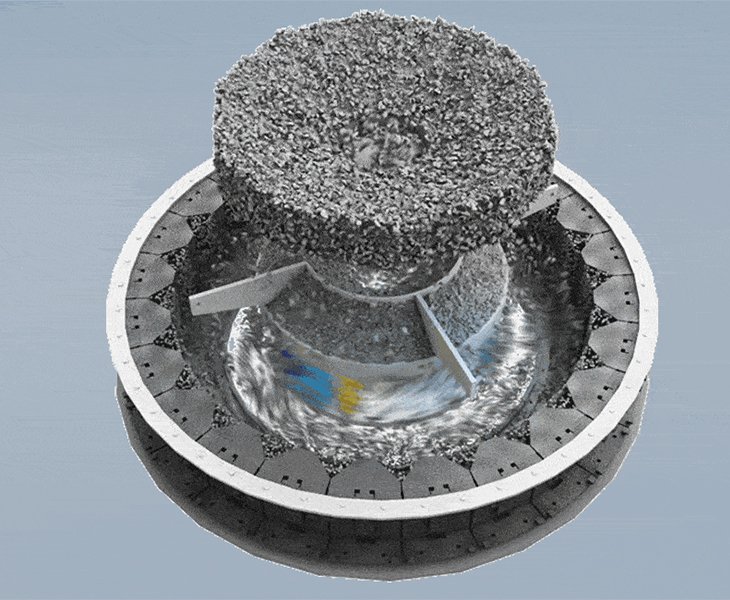

3.1 Rock-on-Rock Crushing

With really abrasive feed, e.g., granite, basalt, quartz, use the so-called auto-genous (selfgrinding) principle.

The rotor, hurling the material outwards, passes it into a stationary bed made up of the crushed rock which forms the lower part of the crushing chamber.

A new bed is formed for each new batch of feed, thus making it selfrenewing, and steel parts receive less wear. Further, as one is using rock to crush rock, the wear cost will be less than by steel on rock.

If your feed is abrasive and your desired product cubical in shape, use the rock-on-rock crushing.

3.2 Rock-on-Steel Crushing

For applications, a high reduction ratio is required (or less abrasive materials are to be processed, such as dolomite or limestone).

When the number of passes is fewer than the number of actual crushes required, the best mode of rock on steel crushing is the Rock-on-Steel (Rock-to-Steel) mode.

In Rock-on-Steel Mode the hard rock is thrown at stationary iron anvils along the perimeter of the crushing chamber.

This quickly results in the hard rock crushing the softer products into very small fragments virtually at the moment of contact with the anvil.

Basically this results in a considerable size reduction of material from approximately 50mm to a few milli metres, all in one pass through the crusher.

4. The Walkthrough of VSI Crushing Machine

The following are the steps used in the VSI Crusher process and how the components work together as one unified machine and method to yield finished product from the raw materials we feed into it.

4.1 Feeding

We transfer into the VSI Crushing process by loading our raw material into the feed hopper of the VSI Crusher, (i.e. quarried rock or ore) where the material is disbursed from the feed tube, which is steered by the cascade tube and onto the Guide Table.

4.2 Acceleration

Once the material is on the Guide Table, it is then directed into a rotor.

The fast-spinning rotor will create a centrifugal force that pulls it away from the rotor and pulls it in towards the impact tips of the rotor.

4.3 Ejection

As the material reaches the far edge of the rotor, the vanes fling it outwards, much like children on a merry-go-round throwing balls when they reach the end of their ride.

4.4 Impact

The real, live effect of impact between these particles takes place at that instant.

If the material is rock it collides with other pieces of rock (rock-on-rock), or with steel anvils (rock-on-steel), as it leaves the rotor.

4.5 Recirculation & Attrition

Not all particles are the right size on the first impact. If larger pieces bounce back into the chamber they may collide once more with other incoming particles or recirculate around the rotor.

4.6 Discharge

The particle has reached the right size before the screen “punches” through to them; they pass through the discharge gap at the bottom of the Crusher and thence to the screen for separating the oversized material.

5. Conclusion

Should you need help selecting the right equipment, or require more clarification about how to use the VSI Crusher correctly.

If you want a file of VSI Crusher PDF, contact us now! We will be happy to talk to you about your needs.

FAQ

1.What Are The Advantages of the VSI Working Principle?

- Superior Product Shape: Making highly cubical shaped particles.

- Control of Gradation: Allows the ability to meet the needs of project details without changing equipment.

- Mineral Reduction Ratios: Less of these stages will reduce time, space, and energy.

- Versatility: You can use a VSI Crusher on Hard Rock, Industrial Minerals, or manufactured sand.

- Efficient Production of Manufactured Sand: The product produced by the VSI will always be the same quality and meets ASTM.

2.What Are The Common Applications of VSI Crushers?

Aggregate Production: Where high-quality aggregates are required. The cubical shape of the output product helps make better concrete and asphalt.

Manufactured Sand (M-Sand): Sand that has to be produced for use in concrete, mortar, or plaster. This is a highly important basis in construction of a perfect area where it can happen naturally – time to produce.

Mining & Quarrying: Tertiary and quaternary crushing of ore, etc. (iron ore, limestone etc).

Industrial Mineral Processing: Shaping and grinding of minerals (e.g., quartz, feldspar, and calcite ) for ceramics, glass, or plastics.

Recycling: Rubble from concrete or asphalt into aggregates used in roadbase or pathways.