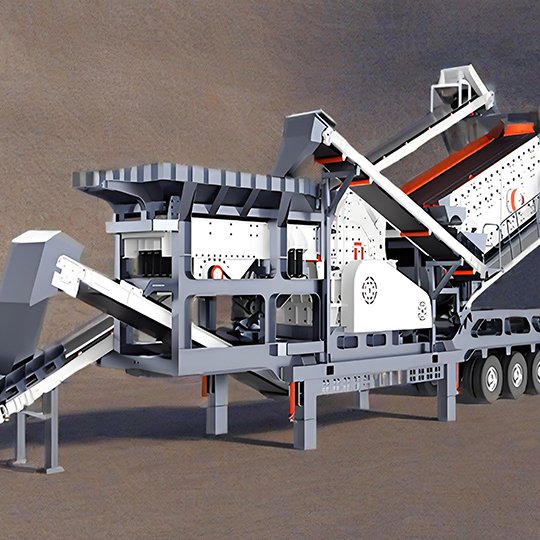

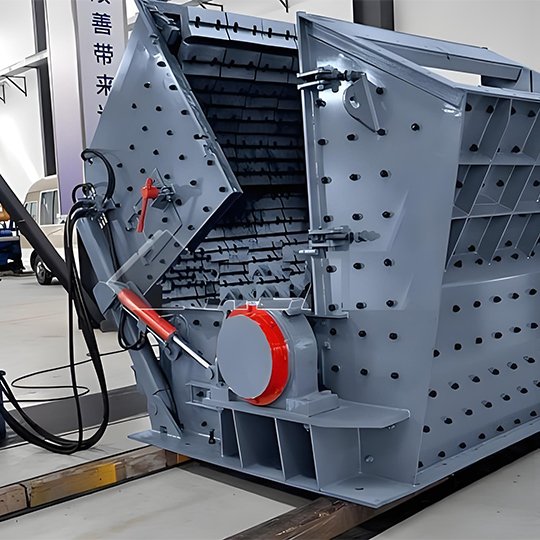

The Stone Crusher serves as the Crushing Equipment in mining, construction materials, and similar sectors. Its effectiveness plays a crucial role in influencing both costs and production output. Nonetheless, frequent issues such as clogs, excessive energy use, rapid wear and tear, and subpar productivity can significantly hinder Stone Crusher machine’s performance.

Today, we’ll explore five practical approaches to improve efficiency that will enable you to swiftly achieve high-performance operation from your Stone Crusher!

1. Optimize Feeding Conditions

Feeding is the first step in the Rock Crusher’s operation. It directly affects the smoothness of subsequent processes. Often, low efficiency isn’t an equipment issue but stems from problems in the feeding stage.

1.1 Optimize the Feeding Process

Uniform and Continuous Feeding: Avoid “surge flow” feeding. It is recommended to use a vibrating feeder to ensure material enters the Stone Crusher’s crushing cavity steadily and continuously, preventing idling or overload.

Strictly Control Feed Size: The Stone Crusher‘s feed inlet and Crushing Chamber have specific size adaptation ranges. Strictly prohibit feeding oversized material, as it can block the feed inlet and damage hammers and liners.

We recommend that you:

Add Pre-Screening: Install screening equipment before feeding to pre-remove oversized material.

Control the Upper Limit: Ensure the maximum feed size does not exceed 80% of the Crushing Equipment’s feed inlet size.

Ensure Uniformity: Keep the feed particle size consistent for balanced force distribution in the Rock Crusher crushing chamber and improved efficiency.

1.2 Control Material Moisture to Reduce “Buildup and Blockage”

Excessively wet material tends to adhere to the inner walls of the Crusher Chamber, feed inlet, and discharge outlet, causing buildup and blockages that reduce speed and increase load. Excessively dry material generates excessive dust, affecting the working environment and Stone Crusher equipment lifespan.

We recommend that you:

Control Moisture Content: Generally recommended between 5%-10%.

Adapt to Material Type: Requirements can be relaxed for materials like coal and clay, but must be strict for sand and gravel.

Handle Overly Wet Material: Pre-dry or sun-dry it to prevent sticking and blockages.

Handle Overly Dry Material: Spray water appropriately to suppress dust.

2. Perform Regular Equipment Maintenance and Part Replacement

2.1 Regularly Inspect and Replace Wear Parts

Wear on core parts like hammers and liners leads to increased crushing gaps and reduced stone crushing productivity.

We recommend that you:

Regular Inspection: Conduct weekly checks and replace Stone Crusher parts exceeding wear limits (e.g., replace hammers if wear exceeds 30% of original size).

Spare Parts Management: Maintain reasonable inventory to avoid unexpected downtime waiting for Stone Crusher parts.

Proper Installation: After replacement, ensure Stone Crusher parts are securely installed to prevent loosening and subsequent failure.

2.2 Use Compatible Wear-Resistant Parts

Stone Crusher wear parts directly impact efficiency and cost. Invest in materials suited to the ore characteristics to avoid the higher cost of frequent replacements due to cheap crusher parts.

We recommend that you:

Hard Abrasive Ores: Stone Crusher parts use Manganese Steel, which work-hardens under impact.

Medium Abrasive Ores: Stone Crusher parts use High-Chromium Steel, offering better corrosion resistance and energy efficiency.

Complex Conditions: Stone Crusher parts recommend Composite Materials for a balance of hardness and toughness.

2.3 Prompt Lubrication of the Transmission System

The transmission system serves as the “power hub” of crushing equipment. Inadequate lubrication leads to Rock Crusher’s increased friction and higher energy usage.

Here are our suggestions:

Adhere to the Stone Crusher manufacturer’s guidelines; monitor oil levels and cleanliness weekly.

Replace oil every month or at least every two weeks in heavy-duty situations.

Frequently clean the lubrication system to avoid blockages caused by contaminants.

3. Adjust Operational Parameters Reasonably

Using fixed parameters for materials with different hardness, toughness, and size requirements makes it difficult to achieve optimal crushing results.

3.1 Dynamically Adjust the Discharge Gap to Match Output Needs

The Stone Crusher discharge gap size directly determines final product size and capacity: a larger gap increases capacity but yields coarser product; a smaller gap gives finer product but reduces capacity and increases energy consumption.

We recommend that you:

Adjust as Needed: Increase the gap for coarse aggregate; decrease it for fine aggregate.

Verify Results: After adjustment, conduct a 10-15 minute test run and sample check the product size.

Prevent Overload: When reducing the gap, simultaneously control feed size and speed to prevent overload.

3.2 Optimize Crusher Speed to Balance Efficiency and Energy Consumption

The speed of a Stone Crusher machine affects impact force: high speed increases efficiency but also wear and energy use; low speed leads to insufficient impact and poor crushing.

We recommend that you:

Reference Baseline Speeds: Jaw Crushers typically 200-300 r/min; Impact Crushers 800-1200 r/min.

Adjust Based on Material: Increase speed for hard material; decrease for soft material.

Monitor Load: Use motor current as an indicator; reduce speed if current is consistently high.

4. Improve Working Environment and Optimize Process

The working environment and supporting equipment also significantly impact the Rock Crusher’s efficiency.

4.1 Ensure Standardized Installation to Reduce Vibration

Improper leveling or loose fixing causes strong vibration during operation, affecting precision, accelerating wear, and potentially shifting the Crushing equipment.

We recommend that you:

Anchor the Stone Crusher machine on a solid foundation, ensuring levelness error ≤0.5mm/m.

Regularly tighten anchor bolts and add damping pads between the equipment and foundation.

4.2 Optimize Process Flow Design

Apply “More Crushing, Less Grinding”: Reduce material size as much as possible in the crushing stage to lessen the load on downstream mills, significantly lowering Rock Crusher overall energy cost.

Set Reasonable Crushing Stages: Use multi-stage combinations for high-hardness materials.

Pre-Screening: Remove already qualified fine material before crushing to avoid re-crushing.

Checking Screening (Closed-Circuit): Screen crushed product and return oversized material for re-crushing, ensuring final product quality and increasing system throughput.

5. Raise the Skill Levels of Employees

Operators are a crucial element in the efficient and safe operation of Stone Crushers.

5.1 Carry out Structured Instruction Programs

Most of the operational errors are due to a lack of knowledge of the principles of the Crushing Equipment, settings and the properties of the various materials.

We suggest that:

– The structure of the Stone Crusher machine, the parameters setting, and safety aspects should be clearly stated.

– Practical tests after the theory should be given to ensure that the operators can adjust the settings themselves and carry out the necessary daily inspections.

5.2 Establish Standard Operating Procedures

In the absence of standardised procedures, it is likely that the operations will lead to machine failings.

We suggest that:

– The Standard Operating Procedures should be drawn up. The methods of installation, starting, running and shutting down the crushing plants should be laid down.

– Flow charts should be posted on the working site, and spot checks made to ascertain the operator’s compliance with standard procedure, and errors corrected.

5.3 Raise the Emergency Ability Level

Stone Crushers can be unlooked for faults such as chokes, or abnormal noise or temperature rise. If the operators take the wrong action the result may be a prolonged period of lost production.

We recommend:

A Stone Crusher machine troubleshooting manual should be compiled and operational drills conducted regularly.

-An effective communication mechanism must be established between operating and maintenance personnel to enable rapid resolution of various faults.

Conclusion

As a Stone Crusher machine supplier in China, we are confident that the aforementioned methods will prove highly beneficial for your Stone Crusher.

Should you encounter any specific issues during operation, or require bespoke solutions for your aggregate production line, we remain at your disposal. Please do not hesitate to contact Sandreck.