Are you unnerved by the number of varieties of Stone Crusher when you come to make the selection? The wrong selection will result in not only a waste of money and delays, but possibly an inferior quantity and quality of output, with a direct injury to project profits.

But don’t fret much! This article will enlighten you on the characteristics of seven of the common Stone Crushers, and thereby enable you to discover exactly the right “profit-producing tool” for your exact working conditions.

Complete Analysis of 7 Common Stone Crushers

1. Jaw Crusher – The Firm Bedrock of Coarse Crushing

Function: The coarse crushing “work horse,” and absolutely essential in laying the bedrock for nearly every crushing line.

Advantages: Simple and robust structure, involves little attention; large feed opening for large rocks; low price, making low initial outlay necessary; adaptable to many varieties of material.

Disadvantages: Crude form of product, necessitating some shaping over if form required is high; considerable vibration and noise, necessitating ordinary precaution at the site.

Use: Most satisfactorily used in conjunction with medium/fine crushers, such as Cone or Impact Crushers, so as to make a complete and reliable production crushing line.

2. Cone Crusher – The Energy-saver for Hard Rock

Function: The medium/fine crushing “specialist,” especially for high-hardness materials, such as granite and basalt.

Advantages: Long-wearing parts;stable working; the infrequency of breakdowns; low consumption of energy, making operational costs more predictable

Disadvantages: Complicated structure; high outlay for purchase and maintenance; prone to moist materials or “claying” materials; defective in choking.

Use: Works with the Jaw Crusher as the “golden combination” for high volume hard rock work.

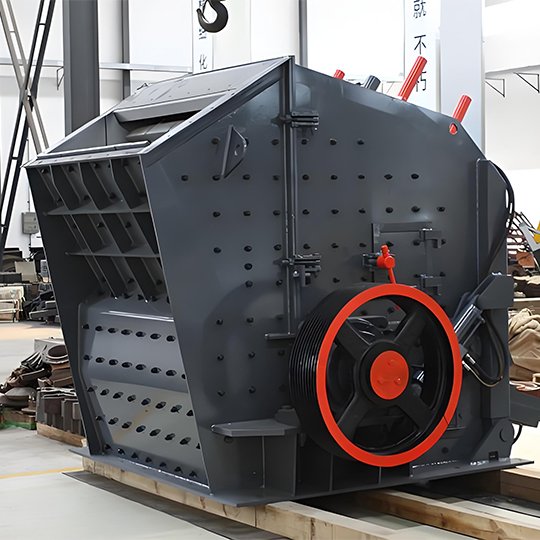

3. Impact Crusher – The Aesthetic Master of Aggregate Shaping

Function: A “dual-purpose” machine for medium/fine crushing and aggregate “shaping”—your top choice if you prioritize excellent product shape.

Advantages: Excellent cubic-shaped end product, good market appeal and performance; high reduction ratio simplifies the process; easy adjustment of output size.

Disadvantages: Faster wear of blow bars and impact plates; higher wear part costs when processing hard materials—factor this into your operational budget.

Use: Pairs perfectly with a Jaw Crusher for medium-hard materials like limestone, producing high-value, quality aggregate.

4. VSI Crusher (Sand Maker)-The Power Centre of Manufactured Sand

Function:This is a “three-in-one” machine, fine crushing, sand making, and shaping—this is the power centre of all manufactured sand jobs.

Advantages: It produces a well-shaped regular size of sand complying with the requirements of building construction in addition to improving the shape of the aggregates producing a better quality product.

Disadvantages: This machine is only for fine crushing/sand making, it needs a pre-crushing machine for the primary crushing (Jaw Crusher) for the secondary crushing (Impact Crusher/Cone Crusher).

Use: Suited for the final position in production making it valuable to the product-an important machine in the professional sand outfit.

5. Hammer Crusher-High Efficiency Note for One Stage Crushing

Function:A good working operation finishes coarse and medium crushing in one stage, simplifying the whole operation at one blow.

Advantages: High crushing ratio-the final particle size of the material is arrived at in one pass through the machine, simplifies the whole operation with less equipment necessary, low initial cost with qualifications for tight budgets.

Disadvantages:The hammers wear out fast requiring constant hammer changes; high consumption of electrical energy; unsuitable for high hard materials such as granite.

Use: Best in small to medium projects with tight budgets, crushing medium to low hardness materials such as limestone, an attractive value-for-money set of machines.

6. Mobile Crushing Plant-Mobile Operations Specialist.

Function: An incorporated “mobile production line” combining feeding, crushing, screening and conveying on the same machine, thus making all operations on the same chassis allowing immense flexibility.

Advantages: No foundations or in features necessary; quickly on the job and the operating time is not long; can work right on face giving great flexibility (i.e. demolitions or mines which are dispersed), no transport costs.

Disadvantages: The costs of the units are more costly than conventional equipment; as a general rule the throughputs are less than for the stationary types of equipment.

Use: Suited for the purposes of recycling of building waste, short-period projects or mines especially where the machinery will constantly be moving about.

7. Double Roll Crusher-Fine Crushing Specialist.

Function: Fine crushing specialist and sand making machine and medium crushers.

Advantages: Very low over-crushing, thus minimizing the waste of material; compact ideas, small in space; low dust emission making it easy to cope with the stricter health and hygiene laws; easy to look after.

Disadvantages: Processing capacity is relatively low; can’t cope with large and huge high hard sediments, hard too fastidious with the feed particle size ≤30mm).

Use: It can process raw materials such as limestone and river pebbles to produce standard-compliant construction sand and railway aggregates; it can also perform secondary crushing of coarsely crushed iron ore, gypsum, etc.

Four golden Rules to Help You Easily Choose the Right Rock Crusher

Make use of these four rules to leap from guess work to an educated decision.

Rule 1: Fit the Crusher to the Material

Hardness/Abrasiveness: For hard rocks (i.e. granite, lava) employ “Jaw Crusher+Cone Crusher.” For soft rocks, (limestone) employ “Jaw Crusher+Impact Crusher” or Hammer Crusher

Feeding Size: If your feed is large (>500mm diameter) employ a Jaw Crusher. Medium size feed can be fed directly to the secondary stage, the first stage can be omitted.

Moisture/Clay Content: If the material is wet or sticky run away from Cone and Impact Crushers (they will choke). The Jaw Crusher can be modified to accommodate this type of material.

Rule 2: Fit the Machine to the Product

Size & Classification of Grain: Want simply aggregate? “Jaw Crusher+Cone/Impact Crusher” is sufficient. Want a large quantity of M-sand? You must add a Sand Maker to the process.

Grain Shape Requirement: Want to manufacture high class concrete or quality aggregate? Use a Impact Crusher or (VSI Crhsher)Sand Maker for grain shape. For Ordinary Constructor material a Cone or even a Jaw Crusher is sufficient

Rule 3: Right Size the Equipment

Small Size (<100 t/h): For small size Plants Heavy Hammer Crusher (single stage) or a “Small Jaw Crusher+Small Secondary Crusher” will be all that is needed, either will be satisfactory and economic.

Large Size (>200 t/h): For plants which give high out-put multi-stage combinations such as “Jaw Crusher+Cone Crusher+Sand Maker” will be needed, if you want stable and high volume production.

Rule 4: Weight Up Static Vs Mobile Crusher

The choice between a fixed installation or a mobile machine is essentially dictated by the conditions at the place of work:

If it is a fixed site where the raw materials are available nearby, and there is a need for great output and continuity of supply, it is advisable to fix the installation.

If, on the other hand, the conditions of work are of variable character, the raw materials different in character, and frequently the place of work changes, then a mobile plant is preferable.

Practical Application: 3 Classic Scenarios – Ready-to-Use Solutions

Scenario A: Granite Quarry of Large Size

Your Requirements: A process for working high hardness granite, large output (> 300 t/h), a control of the long-range cost of operations.

Recommended Solution: Stationary Jaw Crusher + Stationary Cone Crusher + Sand Maker.

The Jaw Crusher will effect primary crushing, the cone will perform the medium/fine crushing of the hard rock and the Sand Maker will give the final treatment to the product.

An efficient arrangement producing a premium quality aggregate or M-sand will afford a better profit.

Scenario B: Medium-sized limestone Sand Making Project

Your Requirements: A process for working medium hardness stone limestone, producing quality aggregate and fine quality M-sand, output 100 – 200 t/h.

Recommended Solution: Stationary Jaw Crusher + Stationary Impact Crusher + Sand Maker. The Jaw Crusher is for primary crushing, the impactor for second stage crushing of suitable shapes and production of sand by means of a Sand Maker. As a combination there will be an excellent quality shape and production of high quality material for the purposes indicated.

Scenario C: Building Waste Recycling.

Your Requirements: The working of a range of material (concrete blocks, bricks), non fixed site, need for prompt transfer.

Recommended Solution: Mobile Jaw Crusher + Mobile Impact Crusher (or a single Mobile Heavy Hammer Crusher).

No foundation work needed, just proceed to the site of demolition material and get to work. Will be an easy matter for transfer from time to time and therefore suitable for your requirements.

Conclusion

There is no “best” Stone Crusher, only the “solution best suited to your problem.” Hopefully, this article has helped you choose a Crusher that meets your needs and achieves ideal results. However, every project has its unique challenges, and general solutions need to be tailored to your specific circumstances.

Contact us (Sandreck Mining Machinery). We are committed to providing you with customized, free consulting solutions.