In the world of aggregate processing, recycling, and even mining there are few machines that are as well known and integral as the Hammer Crusher. Known for its simplicity, reduction ratio, and sheer brute force, this powerful piece of machinery is fundamental for reduction in materials size.

Sandrek, is designed to explore the operation, components, and applications for a Hammer Crusher and will give you the knowledge to identify ways to improve your crushing operations.

The Core Principle: Impact and Attrition

A Hammer Crusher operates on the straightforward yet highly effective principle of impact crushing.

The process is a dramatic one: large feed material is shattered into smaller fragments by the high-speed impact of hammers. This is combined with attrition, where particles are ground down further by rubbing against each other and the interior liners of the crusher.

Unlike the gradual compression of a Cone Crusher, a Hammer Crusher applies rapid, explosive force, making it exceptionally efficient for breaking down softer, non-abrasive materials like limestone, gypsum, coal, and recycled construction debris.

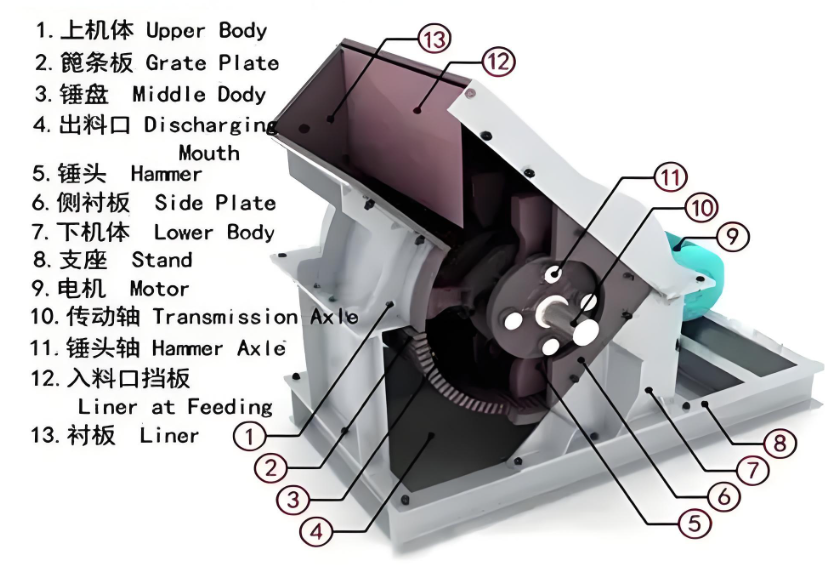

Hammer Parts: Deconstructing the Machine

Familiarity with the Hammer Crusher and its fundamental parts is necessary to appreciate the Hammer Crusher’s operation.

Rotor: The heart of the machine. This is a rotating shaft transmitting kinetic energy to the hammers at high speed. The rotor is a shaft located in a housing on heavy duty bearings.

Hammers: The implement of the crusher. The hammers are a movable impact component on the rotor which are individually or fixed to the rotor. A hammer usually consists of a rectangular metal block made from high wear resistant manganese steel or other alloys.

Grates / Screen Bars: In the lower half of the crushing chamber, the grates are interchangeable, perforated screens that regulate the final product size. Once the material has been crushed by hammer to a size less than the opening of the grate, it passes through the grate and is discharged. The size and shape of the grate directly influences the output gradation.

Breaker Plates: The breaker plates (static liners) are the walls of the crushing chamber. When the material is projected against the breaker plates, it subjects the material to further impact and attrition which aids in the size reduction process.

Hopper: This is where the raw product enters the machine.

Hammer Crusher Crushing Process

The action of a Hammer Crusher is a continuous, high-speed cycle divided into several important steps:

Feeding: The first step is to feed the raw material into the crusher from a feed hopper. The feed has to be controlled and even and is important both for maximizing efficiency and protecting the machine.

Initial Impact and Pounding: At this pint of the process the crusher’s chamber is occupied with raw material and as the material is added to the chamber, it will be struck by the free-swinging or fixed hammers on the rapidly spinning rotor.

Acceleration and Double-crushing: The initial impact will also thrust the material outward toward the breaker plates lining the chamber walls. When the material is thrown against these plates it will rebound back toward the hammers.

This interaction creates a continuous cycle of impact; hammer to rock, rock to plate, rock to rock.

Sizing and Discharging: The impacts continue until the material is small enough to fit through the gaps of the grate screen located at the bottom of each chamber.

The smaller broken material will exit the chamber as the bigger material remains behind to be re-broken and ground into a small enough size before it can escape.

Why Hammer Crusher Operation Is Important

The Hammer Crusher may be simple in design, but operating and maintaining it correctly have serious implications. Rotor speed, grate size, and hammer wear all add to the cost of the product, and these three key areas influence both performance and cost.

Rotor Speed: More speed produces finer products; however, speed also leads to wear and more energy consumption.

Grate Size: The grate size and shape you choose are the primary means of controlling the specification of your finished product.

Hammer Wear: Worn hammers do not perform efficiently, use more energy, and produce a poorer product size. The most important thing you can do is regularly check the hammers and rotate or replace them. One of the most effective ways to reduce operating costs and increase uptime is to use hammers made from high quality durable materials from a reputable supplier such as Sandreck.

Benefits of Using a Hammer Crusher

Large Reduction Ratios: capable of converting large feed into a fine product in one step

Operation and Maintenance: designed for convenient operation and maintenance

Low Initial Costs: typically relatively low cost compared to other crushers

Multiple Outputs: has the versatile ability to produce different product sizes just changing the grate screens.

Partner with Sandreck for Unmatched Performance

Sandreck is specialists in manufacturing and supplying high-performance wear parts engineered for the toughest applications.

Our Hammer Crusher components are crafted from advanced materials designed to extend service life, improve crushing efficiency, and significantly lower your cost per ton.

Don’t let wear parts downtime hammer your productivity.

Choose Sandreck for reliable, durable, and expertly engineered solutions!