Flotation Equipment

Flotation equipment refers to machinery used for carrying out the mineral flotation process. Sandreck flotation Cell are widely suitable for the separation of various minerals, including:

![]() Non-ferrous metals: Flotation recovery of copper, lead, zinc, and nickel ores.

Non-ferrous metals: Flotation recovery of copper, lead, zinc, and nickel ores.

![]() Precious metals: Extraction and concentration of gold and silver ores.

Precious metals: Extraction and concentration of gold and silver ores.

![]() Non-metallic minerals: Purification and beneficiation of phosphate, graphite, and fluorite.

Non-metallic minerals: Purification and beneficiation of phosphate, graphite, and fluorite.

![]() Coal industry: Efficient separation of clean coal from waste rock.

Coal industry: Efficient separation of clean coal from waste rock.

Your Expert Flotation Equipment Supplier In China

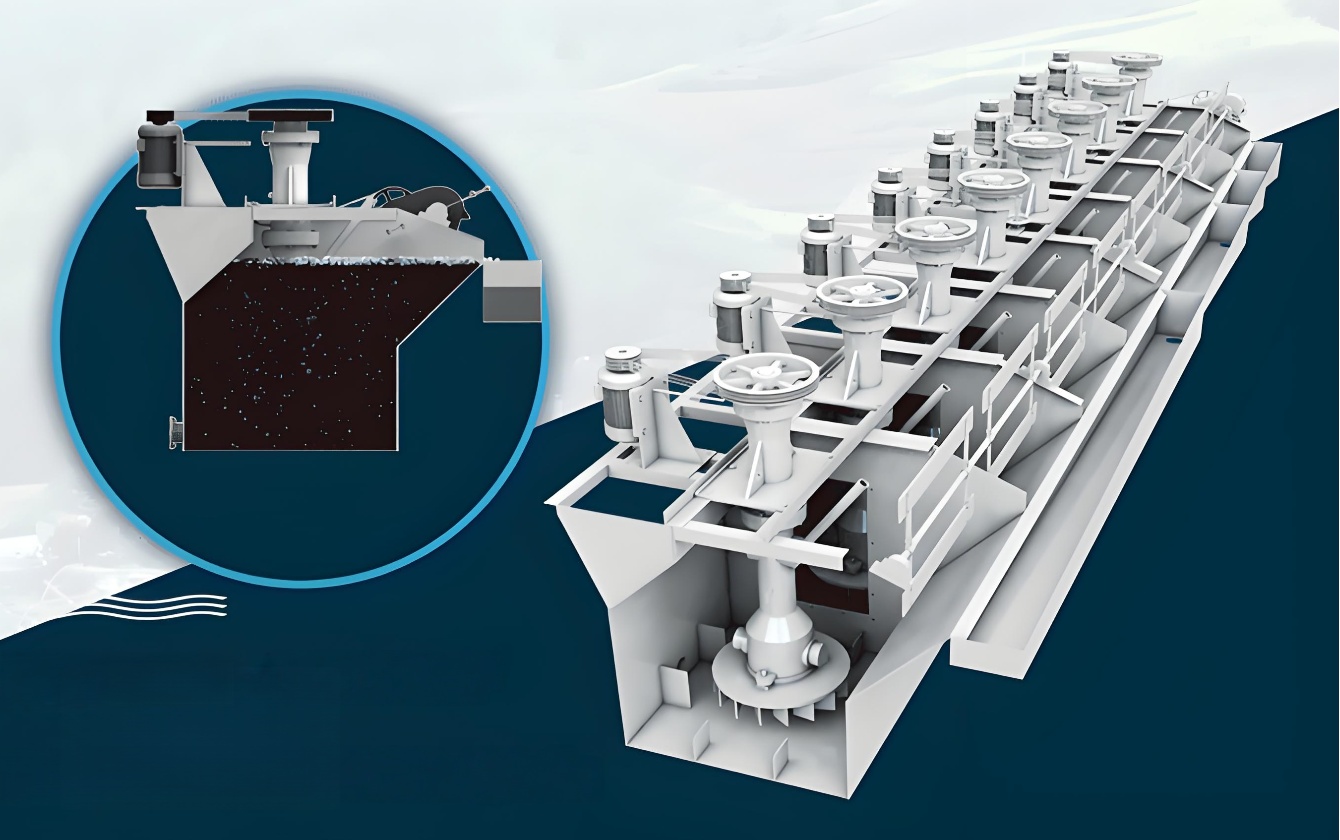

Sandreck is a noted manufacturer of Flotation Equipment for the mining industry in China. As leading manufacturers of flotation machines, we have developed advanced flotation machines, fitted with multi-stage impeller systems.

The Flotation Cells built by Sandreck give excellent service, with power consumption reduced by 30% and increased recovery of valuable minerals through flotation by 20%.

We supply all forms of flotation machines, including machine agitation flotation cells, aerated flotation cell and self-aspirating flotation cells for use in the various processes of roughing, cleaning and reverse flotation.

The Flotation Cells sold are made of a high degree of reliability and efficiency, and are admired for the fact that they are now regarded as the preferred choice for flotation cells of modern plants for mineral producing purposes throughout the world.

Product By Features

Sandreck SF Flotation Cell is a high efficiency mineral sorting equipment suitable for coarse mining.

This is an air self-priming flotation cell that uses mechanical stirring to introduce air into the slurry.

Sandreck BF Flotation Cell, suitable for roughing and reverse flotation of a variety of minerals.

This is a self-priming flotation cell designed for shallow tank operations, suitable for complex flotation processes.

This is suitable for roughing and concentration operations in small and medium-sized ore dressing plants.

Sandreck Flotation Equipment Advantages

Specialized tank design and impeller rotor system minimize impurities and maximize concentrate quality.

Our Flotation Cell series, models, specifications, categories are complete, which meet all your needs in your project.

Equipment ‘s efficiency is monitored throughout the entire life cycle, and the automatic control system is used.

Modular tank + adjustable impeller, one machine can process copper, gold and other ores.

Key parts are lined with rubber or polyurethane to extend service life, this can reduce the cost of later maintenance.

Direct sales from the supplier, you can buy the machine at the lowest price, without middlemen to make profits.

Precision Flotation,

Sandreck Flotation Equipment absorbs decades of mineral processing technology and adopts advanced bubble generator and intelligent control system, which can improve the recovery rate of mineral processing production line and improve the aggregate grade of mineral processing production line.

Quick-Disassembly Structure Design

Sandreck’s flotation equipment features a modular quick-disconnect design for the impeller, stator, and bearing housing. This eliminates the need to hoist the entire main shaft during maintenance, reducing routine service time by 60% and significantly increasing equipment operational efficiency.

How Does Sandreck Flotation Equipment Work?

The flotation machine operates based on differences in the physicochemical properties of mineral surfaces, achieving efficient separation of target minerals from waste rock through bubble adhesion. The core process can be divided into three steps:

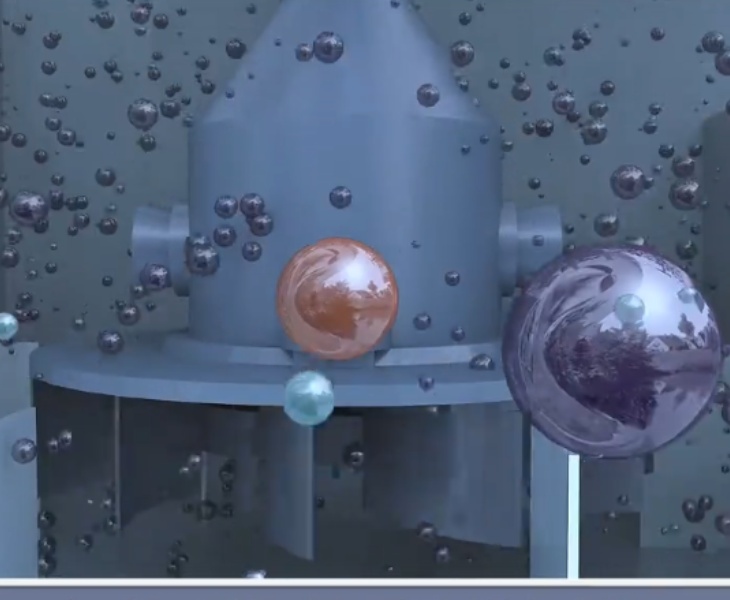

Bubble Adhesion and Mineralization

The ore slurry is mixed with flotation reagents and fed into the agitation tank, where it is fully blended with air by the impeller, generating a large number of fine bubbles. Due to their hydrophobic surface properties, the target minerals selectively attach to the bubble surfaces, forming a “mineralized bubble cluster.”

Froth Layer Formation and Enrichment

The mineralized bubbles rise steadily under buoyancy and accumulate on the surface of the tank to form a mineral-rich froth layer. This high-grade froth is continuously collected as concentrate product via an intelligent scraper system or self-overflow method.

Tailings Separation and Discharge

Gangue particles that do not attach to bubbles remain in the slurry and are ultimately discharged from the bottom of the tank through the tailings disposal system, completing the separation process.

Sandreck Customized Services – Tailored Flotation Equipment Solutions

We analyze your ore properties to customize key parameters for each flotation cell, ensuring perfect integration with your process.

Configure your ideal flotation cell from intelligent controls, aeration modules, and wear-resistant solutions to match your needs and budget.

Our flotation equipment fits your unique layout, saving space and installation costs for both new projects and facility upgrades.

From testing to optimization, we provide continuous support for every flotation system to maintain optimal performance.

Testimonials

The dosage of reagents (mainly foaming agents) should be adjusted in time.

The impeller is too worn, the inflation pipe is blocked, the belt is loose, or the main shaft speed is insufficient.

It may be due to improper bearing, insufficient lubrication, and the entry of debris.

Related Product

Sandreck Magnetic Separation is used to select strong magnetic minerals.

Sandreck Saking Table used for separation of materials with different densities.