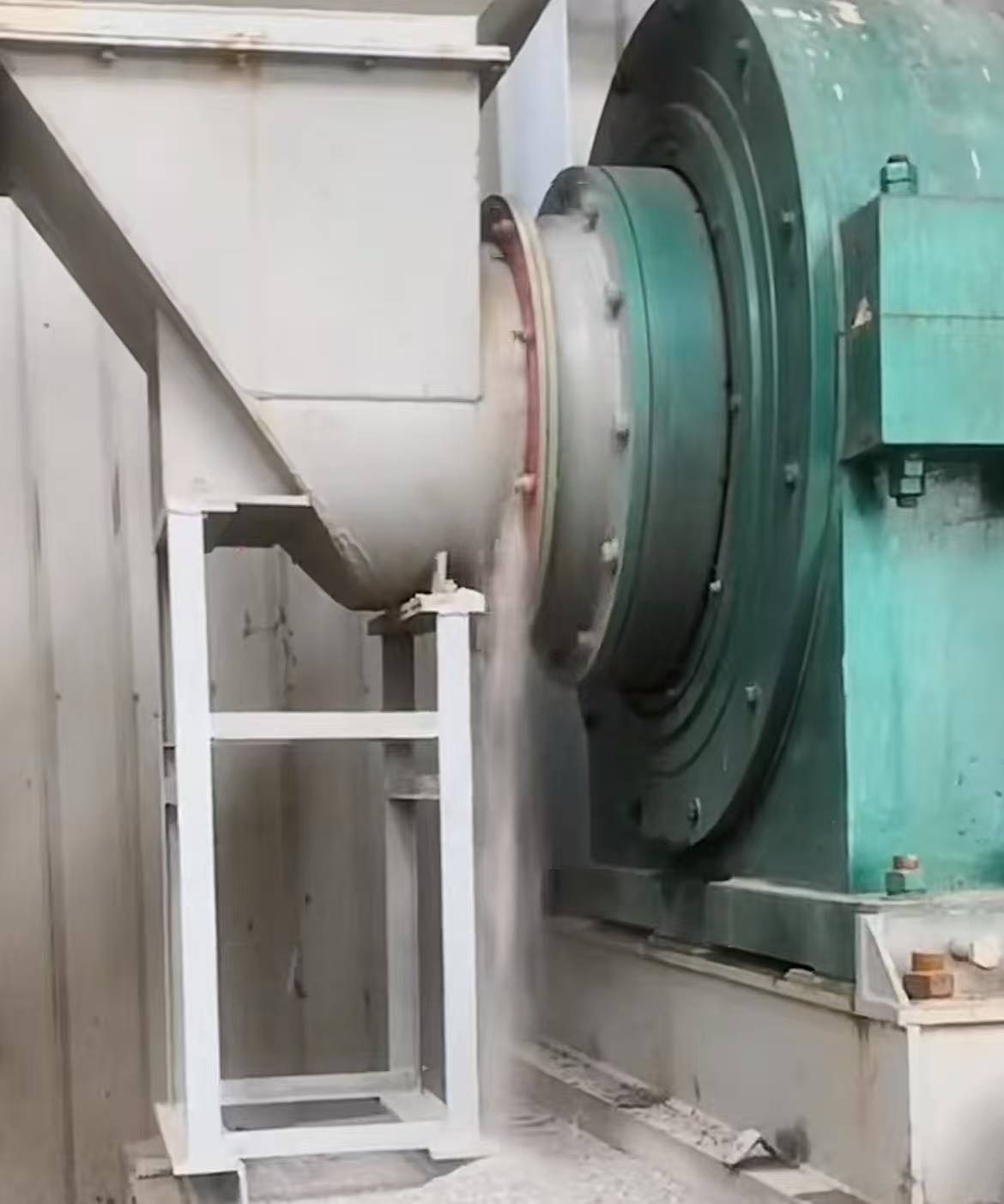

Ball Mills are essential grinding equipment in mineral processing.

This article will discuss five common Ball Mill malfunctions and how to quickly troubleshoot them.

Fault 1 – Vibration and Noise

Symptom: Barricade and society noise can be heard while running, which continually increases.

Cause:

- Within the Ball Mill, the liner or balls have so worn away that it is now impossible to exert any crushing effect between the liner/balls and cylinder wall.

- Some Ball Mill bolts of the key components experience little interference and now have a tendency to slide out-ward, creating noise when the component within which it is located rotates.

- The proper clearance of the pinion and girth gear is not held, and consequently one or both of them are found to be slipping and grinding on each other.

- Some rolling elements or cages have come apart.

Solution:

- Check all the Ball Mill liners and steel balls and replace immediately those that are found to be above the wear limit.

- All loose bolts must be checked and likewise marked and systematically brought back to a fully tight condition.

- Reset gear mesh within specification, apply clean lubricant to the gear surfaces.

- Renew any damage found to the bearings, preventing any further sire hopper or other component from being damaged.

Fault 2 -Abnormal rise of temperature in Ball Mill bearing

Symptom: If the bearing housing gets hot >70º.C, you may feel that the bearing surface is “warm”.

Causes:

1.Lubricant system: Inadequate lubrication, wrong oil type, contamination (dust/moisture) can lead to greater equipment failure.

2.Installation: An incorrectly installed Ball Mill bearing may tend to place unevenly distributed forces on the Ball Mill bearing, causing excess frictional heating.

3.Overload: It is possible over a period of time to overload the motor operating under unacceptable conditions.

Remedies:

1.Check oil levels and cleanliness. Apply the proper type of grease as per proper directions given by the manufacturer of the Ball Mill.

2.Level set with respect to the main shaft centre line and concentric to this. Replace without delay those Ball Mill bearings which show signs of having been subjected to heat, by cleaning Ball Mill bearing housing.

3.Avoid overload: Reduce load on Ball Mill motor, and verify operating load.

Fault 3 – Overfilled Mills or Plugged Mills

Symptom:Material is not discharged (either very little or completely) and the reading on the Main Motor Ammeter often fluctuates down or reading “zero.” Also, a dull grinding sound is heard but no impact noise from the balls.

Causes:

- Feed rate is too high or excessive moisture content causes agglomeration in the material, resulting in the material exceeding the Ball Mill machine’s ability to discharge material.

- Insufficient power to grind due to lack of grinding media and/or lack of lubrication; in previous Events, even though too much material (feed) has been added, the mill cannot grind it.

Solutions:

- Reduce or stop feeding immediately: This is the emergency action to take first.

- Modify physical properties of materials: Reduce moisture and maintain similar size particles when feeding into the Ball Mill.

- Increase grinding ability of the mill: Provide more balls and replace worn liners in order to return the Ball Mill to its original grinding strength.

Fault 4-Lack of Motor Rotation/Overtopping Load Conditions

Symptom:The Ball Mill motor fails to start or rotate after pressing the “start” button or stops rotating a few seconds after starting and the circuit cabinet shows a “high” condition, thermal relay/circuit breaker tripped.

Reasons:

1.Loss of power to one of the three phases supplying power to the motor; voltage too low; control circuit open; or failure of contactor.

2.Except for reasons mentioned above failure of the motor itself or failure of insulation due to age.

Solutions:

1.Check Ball Mill electrical system: Initially check that power is on to the motor (i.e., through circuit breaker), contactors are working correctly and thermal relays are not tripped.

2.Inspect/Repair Motor: Use a megger tester for testing insulation and windings. If the motor faulty, arrange for repair by qualified staff.

Fault 5 – Slurry Leakage from the Discharge/Feed End

This is when the slurry leaks from either the Ball Mill feed inlet or the discharge outlet, or from between the hollow shaft and the end cover of the Ball Mill machine. The leaking slurry not only wastes material, but also pollutes the environment.

Reasons:

- Sealing components have been exposed to prolonged use, aging, or have been damaged by corrosion, and therefore have lost their elasticity which is needed to create a seal with the inner surface of the hollow shaft.

- The bolts that hold the end cover or seal gland to the hollow shaft may not have been properly tightened; this could result in a lack of sufficient sealing pressure.

- The concentration and viscosity of the feed slurries being added to the chamber could have reached a level that the Ball Mill can’t process them. If the internal pressure is too high, it can cause the slurry to leak through the seal.

Solutions:

1. Replace all of the sealing Ball Mill components with new high quality sealing components which are specifically designed to resist wear and corrosion.

2.All bolts should be tightened evenly; check to see that all of the bolts are tightened to provide an equal amount of pressure on the sealing surface of the hollow shaft.

3.Process parameters should be adjusted so that the concentration and / or viscosity of the feed slurries are appropriate to provide adequate time for the mill to process the feed slurries.

Summary

As a Chinese company with more than 20 years of professional experience in the mining sector, we not only offer dependable and stable Ball Mills and related components, but we have also gained significant expertise in managing a range of challenging working conditions. We are aware that every little detail counts. Sandreck is prepared to become your most dependable companion.

Please don’t hesitate to contact us at any time if you run into any particular issues during practice or require expert technical assistance and equipment services.