The correct selection of Ball Mills is highly influential on manufacturing costs and the amount of available ore.

This short article provides an overview of the characteristics of the various types of Ball Mills manufactured by different companies in three minutes or less, so you can quickly determine the best Ball Mill type for your individual needs.

Ⅰ. What is a Ball Mill?

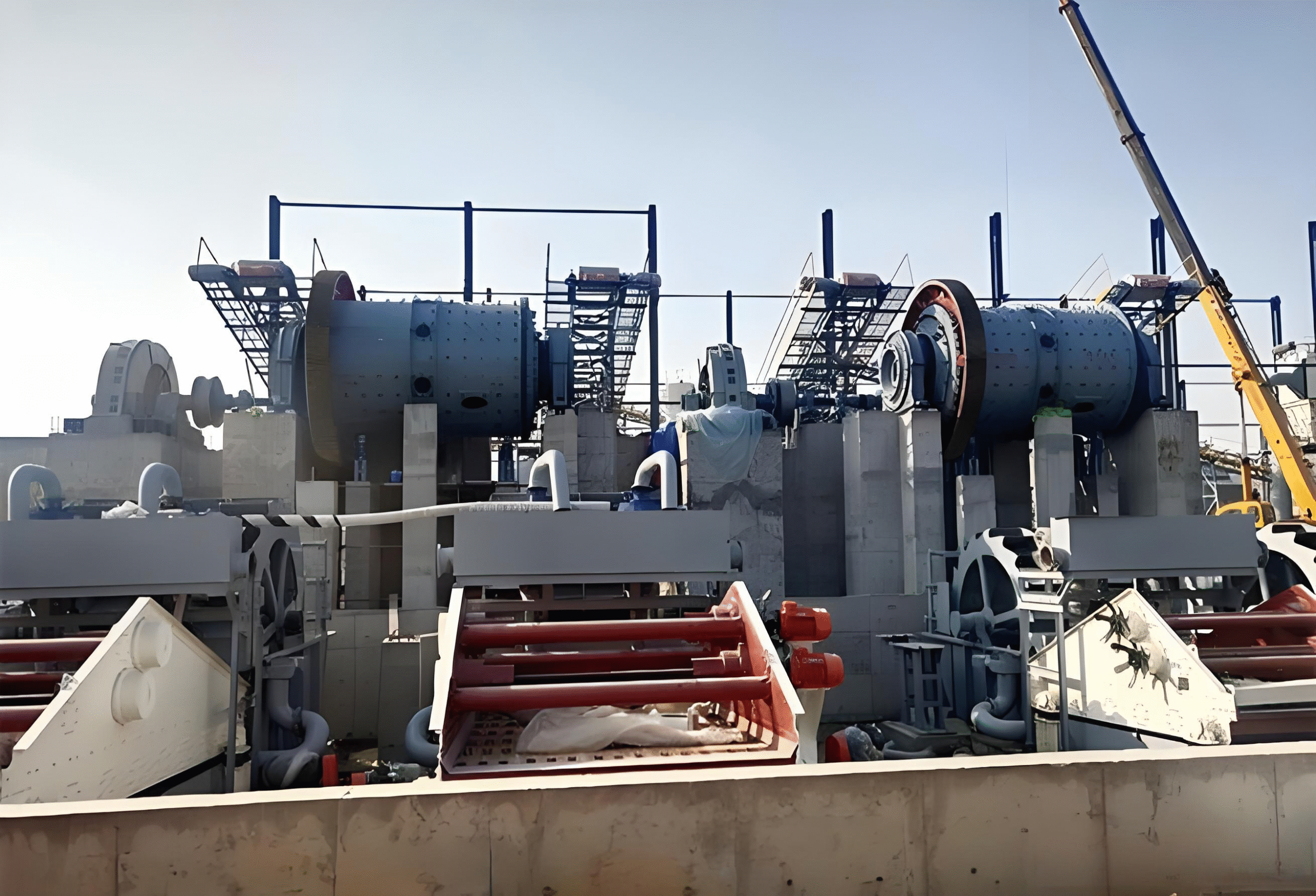

As a core grinding equipment in mineral processing, a Ball Mill consists of a large rotating cylinder containing steel balls (grinding media) and the material to be ground. The material is ground into fine powder through the impact and grinding action of the steel balls.

Ⅱ.The Vital Role of Ball Mills

As the last step of the “crushing” process, a good quality Ball Mill will play a big role in determining the quality of the feed materials for the separation process. Choosing the correct type of Ball Mill will greatly enhance the amount of metal that can be recovered from the concentrate and increase the grade of that concentrate.

Ⅲ.Classification and characteristics of traditional Ball Mills

1.Classification based on the type of grinding process

①Dry Ball Mill

Dry Ball Mill completes the grinding process in a completely dry environment. It has a rather strange processing method, and can be used in several industries such as: Chemical, Construction, Mining, etc.

| Working Principle | The Ball Mill machine rotates the cylinder and drives the grinding media against the material being processed in order to crush and grind it. An air system is used to classify and transport the materials processed through the Dry Ball Mill. |

| Applications | 1. If stickiness brings Problems – not process sticky materials (also perhaps materials containing water e.g.: Cement, Quartz Sand, Coal Dust, etc.) 2. In areas where arid climate, or lack of water exists(Water Scarcity) 3. Where the processes require end-user direct access to dry powder products of grinding process direct from the process |

| Advantages

| 1. Zero water Utilisation / No requirement for treatment of waste water 2.Simplifies the entire process by frees it from having to dehydrate and dry the materials 3. Systems themselves are very simple and therefore necessarily obviously also of less capital investment and lower operating cost. |

| Technical Specifications

| 1. Air classifying system dedicated for separating out processed material 2. Sealed structure to prevent escape 3. Hot air may also be added in operation for simultaneously grinding and drying the materials |

| Limitations

| 1. High requirements for maintaining an effective dust control 2. Cannot process Sticky materials |

②Wet Ball Mill

Wet Ball Mill is a kind of mining equipment which uses water as a medium to carry out grinding operations. It is widely used in the wet grinding process of metal ore and non-metal ore.

| Working Principle | The rotating cylinder drives the grinding media to perform impact grinding on materials in a water-based medium, with material conveyance and classification achieved through water flow or pulp gravity flow. |

| Applications | 1. The processing of minerals (iron, copper, gold), etc. 2. Materials suitable for treatment by hydrometallurgical methods. 3. Applications in which strict dust control is required. |

| Advantages

| 1. Very good grinding efficiency and continuous rapid capacity. 2. The danger of dust explosions is reduced and a cleaner atmosphere. 3. Relatively uniform product, in no way over-reground. |

| Technical Specifications

| 1. Act on gravity flow or pump. 2. Furnish classification devices copy to form a closed circuit system. 3. Special design for anti-corrosive lining. |

| Limitations

| 1. Heavy consumption of water. 2. Rehabilitation of dehydration equipment required. |

2.Classification by ore arrangement (layout)

①Great Ball Mill

This Ball Mill has a forced discharge structure with a grid plate for rapid discharge of the materials. This kind of mill is applicable to coarse grinding operations and to high production lines.

| Working Principle | Grid plate forced to discharge the ore through, and directly and immediately discharged when the size is reached, thus assuring a large percentage of discharge. |

| Applications | 1. To a rough grinding operation 2. To a need of high processing capacity 3. To a process requiring rapid discharge of ore |

| Advantages

| 1. The speed of ore dressing is fast and the processing capacity is large. 2. The grinding phenomenon is relatively mild. 3. The grinding efficiency is relatively high. |

| Technical Specifications

| 1. Special lattice board design and lifting liner structure 2. Adjustable ore discharge concentration 3. High efficiency |

| Limitations

| 1. Structure is quite complicated. 2. Workload for maintenance relatively large |

②Overflow Ball Mill

This kind of Ball Mill equipment uses the ore pulp itself to discharge by self-flow. It realizes the classification of the material by the way of overflow, which is especially suitable for the fine grinding operation and the occasion that needs to obtain the finer product.

| Working Principle | The ore pulp naturally overflows through the hollow shaft neck at the discharge end by gravity to achieve the self-discharge after the material prolongs the residence time in the machine. |

| Applications | 1. Two-stage process with fine grinding or re-grinding of the product from the primary machine in order to produce a very fine product; 2. Processes/products where a fine product particle size is required;Applications requiring a finer product particle size; 3.Processes with very accurate requirements as to particle size. |

| Advantages

| 1. Simple structure, convenient for maintenance; 2. The product will be fine; 3. The machine is stable in operation. |

| Technical Specifications

| 1. Simple overflow discharge; 2. Long cylinder; 3. Adjustable overflow concentration. |

| Limitations

| 1. Low capacity; 2. Susceptible to over-crushing. |

Ⅳ. Determination of Choosing the Right Ball Mill

Want a quick determination of the final model? Take these three steps:

- Deal with properties of materials, are your raw materials water-sensitive? Is the region short of water? If so, it determines the choice of dry, wet process broadly.

- Deal in specifications of products, what degree of detail is required in the final product? What is hourly capacity? This will help determine whether the design should follow a grid-type or overflow-type configuration.

- Combination selection. Thus:

- For dry material to be ground in a cement plant, might do best to obtain – high output definitely is probable -dry type checkered discharge (or other) arrangement.

- For processing copper ore in the plant best high output might be obtained through the first stage of coarse grinding wet in (and possible to keep waste material in) wet type reticulated Ball Mill.

iii) Processing plant concerns gold concentrates, select, from ultra fine grinding point of view, wet Overflow Ball Mill.

Ⅴ. Conclusion and Recommendations

We hope this article is of help to you in quickly grasping the types, characteristics and applicable aim of Ball Mills. Whatever Ball Mill you are looking for, remember «to fit the material and demand»-right attitude is the mother of all efficient production.

In the meantime, we then hope again the article helps you for Ball Mill equipment selection-simply contact and leave all for Sandreck Mining Machinery, where all we do is tailor-made accurate efficient processes to ensure your project timely.

FAQ

Q: Is there a Ball Mill that is always more efficient, the wet or the dry one?

A: Not necessarily, it depends upon the material and the process. Wet Ball Mills are generally more efficient for the grinding of metal ores with which the water medium promotes the flowing together and classification of materials therein. For water sensitive materials of the cement and coal powder type, however, Dry Ball Mills are efficient, saving dehydration and making for a simpler whole process.

Q: Can a single Ball Mill be used for dry and wet grinding?

A: This is not advisable, for dry and wet Ball Mills differ widely in construction, sealing and system of discharge. The mixing of the two types might lead to equipment damage, decreased efficiency and serious hazard.

Q:How to judge whether a Ball Mill is “fitting” preliminary?

A: Can the material be infiltrated? Know the necessary product fineness; depends on the amount of production decided on the type.

Q: Is there a universal Ball Mill?

A: There is no way; having to be adapted to all kinds of material, products and needs, is forced to be universally effective and suffice damages.

Q: What is the easily overlooked point?

A: Downstream operation: need to dewatering or dust removal; Overall cost: Wet Ball Mills reduce saving use electricity, Dry Ball Mills save water, need to remove a lot of expensive dust; Space restrictions: Wet Ball Mill must be equipped with auxiliary facilities and occupy more space.