PF Impact Crusher

PF Impact Crusher is a Stone Crusher that uses impact force to break materials.

- Feed size: 300 – 900 MM

- Motor power: 132-710 KW

- Processing capacity: 90-800 T/H

What Is PF Impact Crusher?

Sandreck PF Impact Crusher is named after the working principle of crushing materials by impact. It can crush materials with a side length of less than 500mm. It’s widely used in various ore crushing, railway, highway and construction industries for artificial sand and gravel production.

Sandreck PF impact crusher is a highly efficient crushing equipment suitable for primary, secondary and tertiary crushing of stone. It uses impact energy to provide powerful crushing force to crush materials such as limestone, concrete and asphalt. It is equipped with heavy-duty rotors, wear-resistant parts and adjustable impact plates to accurately control the particle size of the output. It is an ideal choice for the mining, construction and recycling industries. With its solid structure and optimized crushing chamber, it can minimize operating costs while maximizing production.

PF impact crusher is ideal for processing medium-hard materials, combining durability, versatility and environmental performance. Upgrade your operation with Sandreck PF impact crusher to achieve reliable and cost-effective material processing.

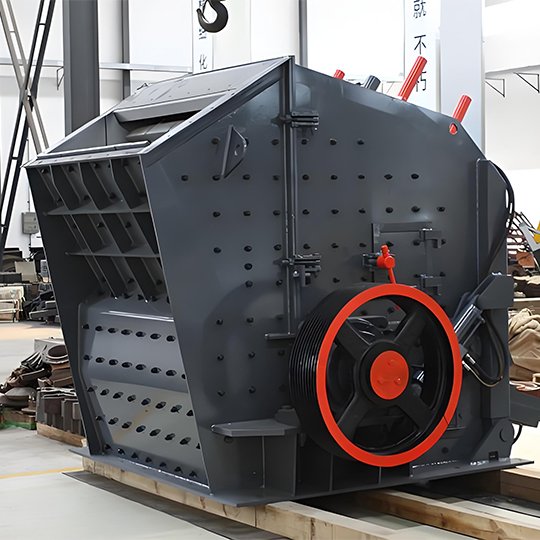

PF Impact Crusher Advantages

Sandreck PF Impact Crusher adopts high chromium manganese plate structure, impact resistance, wear resistance, and strong impact force.

The crushing ratio of Sandreck PF Impact Crusher is large, the crushing efficiency is high, and the product is cubic after crushing.

The gap between the impact plate and the hammer is easy to adjust, so as to effectively control the particle size of the discharge material.

Adopting the traditional classic mechanical structure, Sandreck PF Impact Crusher is cheaper than the full hydraulic system impact crusher.

Two sets of identical ratchet flap devices are installed on both sides of the frame, making it more convenient to replace spare parts.

The compact design of our PF Impact Crusher ensures its high rigidity, and the rotor with high moment of inertia increases its reliability.

Why Choose Sandreck PF Impact Crusher?

Sandreck PF Impact Crusher has the advantages of large crushing ratio and cubic particles after crushing. It is a stone crushing equipment finer than Jaw Crusher. It is used in conjunction with Jaw Crusher in stone production line. The discharge particle size is adjustable and the crushing specifications are diversified.

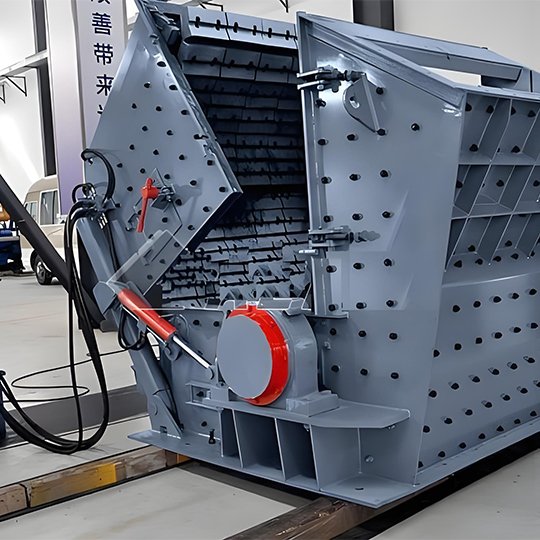

Sandreck PF Impact Crusher Main Components

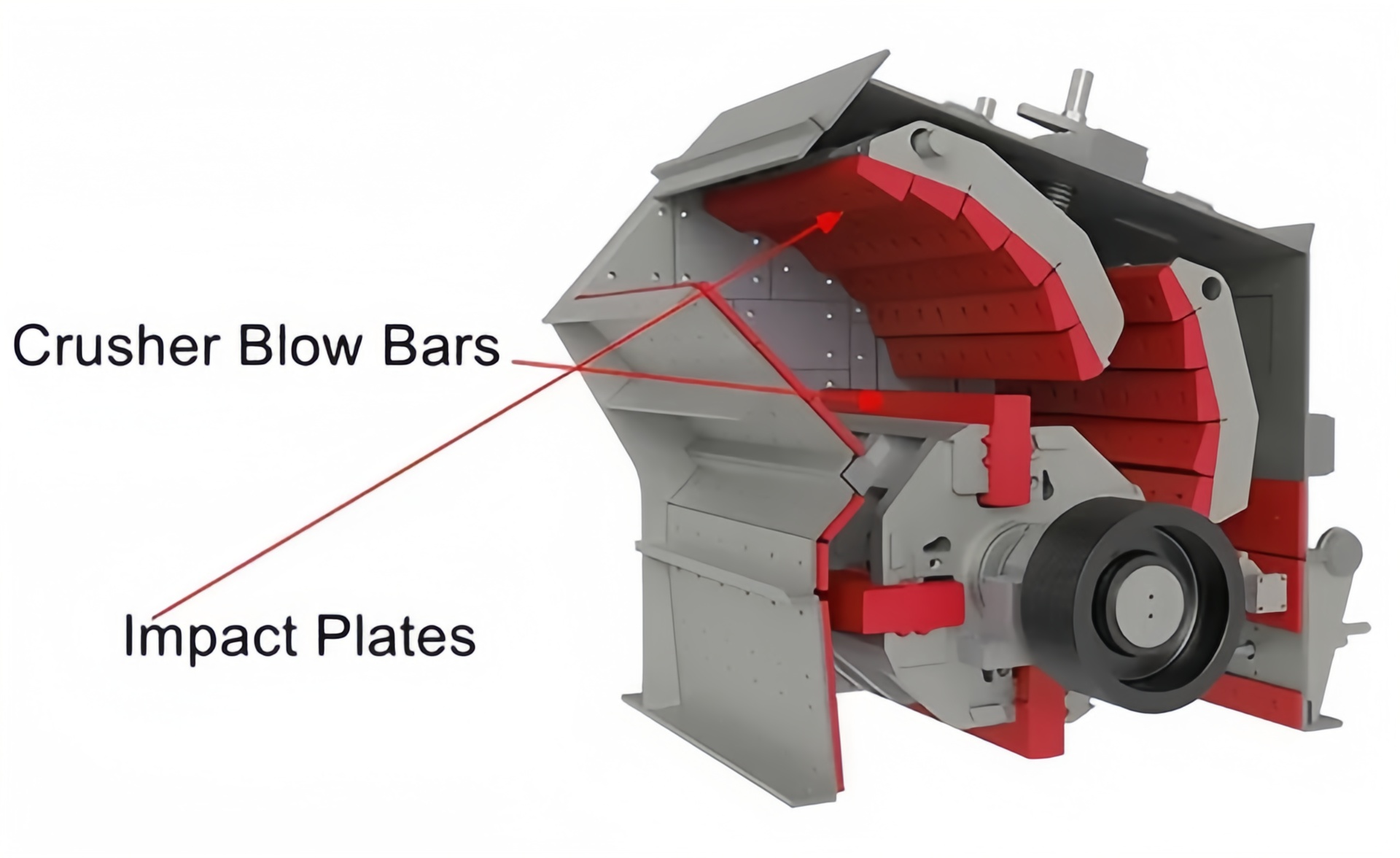

Sandreck Impact Crusher is mainly composed of rotor, plate hammer, impact plate, support plate and adjusting frame, these parts work together to make PF impact crusher can efficiently complete the material crushing tasks.

Company Advantage

Sandreck is a PF Impact Crusher Manufacturing Company integrating R&D and design, production and sales. It possesses over 100 sets of machining equipment of various specifications, including CNC vertical lathes, deep hole drills, laser cutting machines, planers, CNC lathes, CNC boring and milling machines, etc.

We are a PF Impact Crusher corporation. Our crushing equipments are used by customers all over the world because we will tailor professional solutions and mature supporting design plans for you based on your needs, creating the greatest value for you.

Golden Service

For your PF Impact Crusher, we stand by your side 24 hours a day, providing round-the-clock protection for your choices!

We will arrange engineers to conduct actual surveys and scheme designs at your construction site, and provide customized product services according to your needs.

Our production process is clear and transparent, strictly controlled by professional quality inspection, with accurate inventory preparation and timely delivery.

We will dispatch engineers go to the site to provide technical training on equipment installation and commissioning, operation, maintenance and other aspects.

24-hour customer service response mechanism, providing you with technical services throughout the entire life cycle.

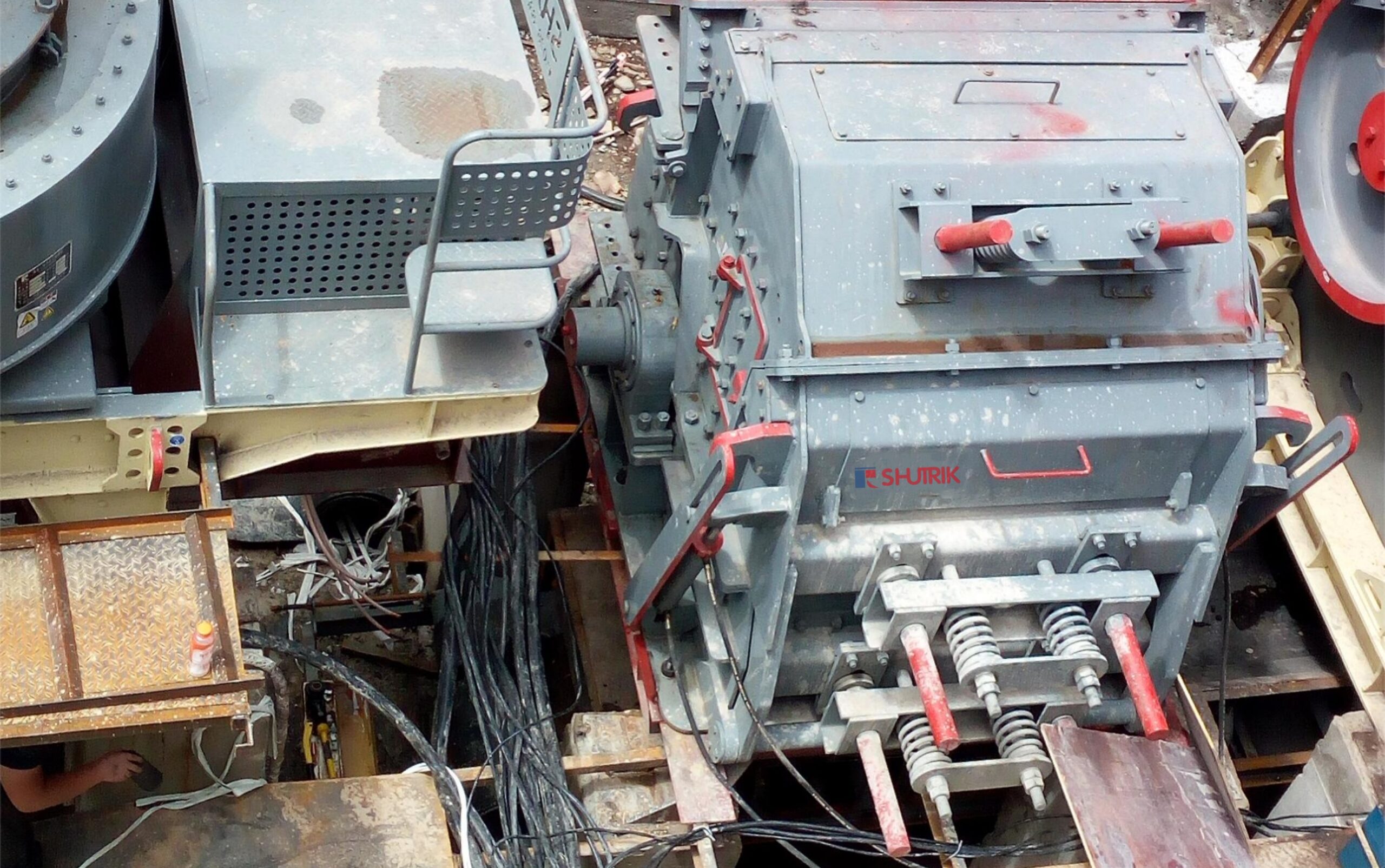

PF Impact Crusher Cases

Sandreck is a well-known Chinese integrated supplier of crushed stone equipment and solutions, and has provided services for over a thousand sand and gravel processing plants.

Processing material: Basalt

Capacity: 300 t/h

Finished size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

Processing material: Granite

Capacity: 200 t/h

Finished size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

Technical Parameters

- PF Impact Crusher

| Model | Specification | Feed Port Size (mm) | Maximum Feed Side length (mm) | Processing Capacity (t/h) | Motor Power (kw) | Overall Dimensions (mm) |

| PF-1214 | ∅1250×1400 | 400×1430 | 300 | 90-120 | 132-160 | 2850×2400×2900 |

| PF-1315 | ∅1320×1500 | 860×1520 | 350 | 120-150 | 180-220 | 3100×2800×3160 |

| PF-1320 | ∅1300×2000 | 900×2030 | 500 | 160-350 | 260-300 | 3320×3218×2613 |

| PF-1520 | ∅1502×2000 | 1315×2040 | 700 | 350-450 | 400-500 | 4138×3422×3649 |

| PF-1820 | ∅1800×2000 | 1620×2040 | 900 | 550-800 | 630-710 | 4471×3250×4008 |

Testimonials

Sandreck PF Impact Crusher is suitable for limestone, granite, iron ore, etc.; river pebbles, cobblestones, etc.; other materials such as concrete, etc.

The equipment needs to be fully inspected and lubricated. After starting, it need to be fed evenly and continuously and observe the operating status closely.

Sandreck PF Impact Crusher includes rotor, plate hammer, impact plate, rear box, liner, main shaft, tie rod, locking block, clamping block, etc.

We are a Chinese crusher source factory, each unit is ex-factory price, you can leave a message via WhatsApp (+8613666293477), we will contact you ASAP.

Related Product

Linear feeding equipment that continuously feeds materials into the crusher.

The crushing ratio is large and the feed particle size can reach 100mm.

Cleans dirt and impurities from sand and gravel to improve the purity of final product.

Used for grading and screening of minerals, quarries, building materials, etc.