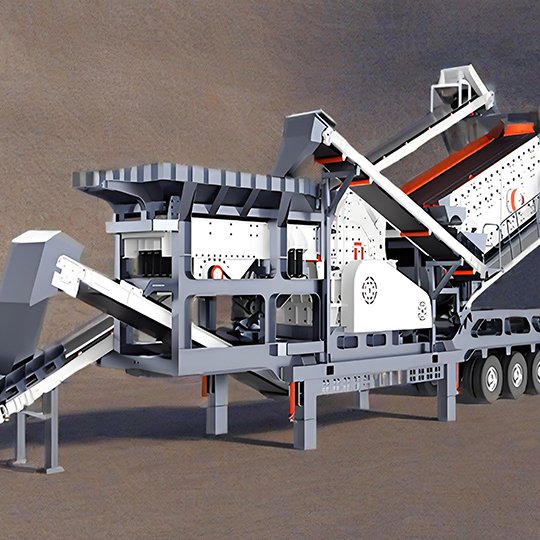

Mobile Concrete Crusher Manufacturer

The Sandreck Mobile Concrete Crusher is a mechanical equipment capable of crushing concrete and construction waste, aiming at the efficient recycling of construction materials.

![]() Capable of crushing concrete with reinforcing bars (and separating them)

Capable of crushing concrete with reinforcing bars (and separating them)

![]() Output size adjustable from 20 mm to 100 mm crushed stone

Output size adjustable from 20 mm to 100 mm crushed stone

![]() Screeners with a capacity of 50 to 350 tons per hour.

Screeners with a capacity of 50 to 350 tons per hour.

![]() Can be diesel or electrically powered

Can be diesel or electrically powered

Mobile Concrete Crusher Supplier in China

Sandreck is a top Mobile Crushing solutions provider based in China that specializes in the manufacturing of Mobile Concrete Crushers designed to crush large concrete blocks at a customers’ construction site and reuse the material on-site.

Sandreck’s Mobile Concrete Crushers are more maneuverable than stationary Concrete Crushers. They can be moved with the project and crush concrete on-site as needed, eliminating the need to transport waste material and turning waste concrete back into high-quality, reusable aggregate.

Our Mobile Concrete Crusher is designed modularly with the whole machine divided into standardized functional modules, – whether it is a demolition site switch, an infrastructure project switch, or an unanticipated construction waste disposal can all transition quickly. Upon arrival, commissioning time is just 30 minutes and the crusher can be quickly operational and crushed.

Mobile Concrete Crusher

Mobile Concrete Crusher can be transported to where it is needed, and can also be easily utilized on construction sites and mines

Mobile Jaw Crushers are highly mobile and utilize jaw crushing technology as their core function. They are suitable for coarse crushing of materials such as ores and construction waste.

Mobile Cone Crushers are Mobile Crushing Plant with cone crushing technology as their core function. They are suitable for secondary and tertiary crushing of hard rock and ores.

Mobile Impact Crusher equipment utilizes impact crushing technology as its core, making it suitable for secondary and tertiary crushing of materials such as ores and construction waste.

Mobile Crushing Plant with built-in sand making functions efficiently produce high-quality sand and gravel, suitable for the production of construction aggregates and manufactured sand.

Crawler Concrete Crusher

If your site is narrow, muddy or soft ground, choose a Crawler Concrete Crusher – all-terrain passage without jams, slopes and mud are still stable!

This Crawler Mobile Crushing station, equipped with a Jaw Crusher, is designed for coarse crushing of hard rock and is suitable for pre-crushing operations in mines, quarries, or other complex terrains.

Combines the fine crushing capacity of a cone crusher with the self-propelled advantages of crawler tracks. Suitable for secondary and tertiary crushing of hard materials and precise grading of aggregates.

Combining the secondary and tertiary crushing of an impact crusher with the mobility of crawler tracks, it is suitable for applications such as construction waste recycling and aggregate processing.

A modular screening machine and crawler chassis for efficient on-site grading and stockpiling of sand, gravel, minerals, and construction waste, saving transportation costs, can be your effective friend in crushing!

Wide Range of Applications

Whether you’re working for a demolition company or doing road construction repairs, the Sandreck Mobile Concrete Crusher is the fast and reliable choice.

Construction/Demolition: It quickly crushes concrete or demolition waste on site, producing high-quality recycled material that can be used for new projects and road repairs. It solves the waste problem and transforms waste into a new source of income.

Road Maintenance: The Mobile Concrete Crusher crushes old concrete blocks on site and turns them directly into new road base material, saving money on freight and new material, and construction is also faster.

Mobile Concrete Crusher - Automatic Release

Considering that concrete comes in all shapes and sizes, oversized objects can easily get stuck. Our Mobile Concrete Crusher is equipped with an automatic release system, so even if an oversized object gets stuck, it can be released at the touch of a remote control, with little wasted working time.

Mobile Crushing and Screening

Our Mobile Concrete Crusher with integrated screening function can produce four types of recycled aggregates at a time:

20-50 mm coarse aggregate, which can be used directly in roadbeds;

10-20 mm medium aggregate, which is ideal for recycled concrete;

5-10 mm fine aggregate, which is ideal for mortar; and recycled fine sand (≤5 mm).

One machine can complete the whole process of concrete crushing and grading.

Why Choose Sandreck Mobile Concrete Crusher

We’re The Manufacture

We’re a professional Mobile Crusher manufacturer with over 100 state of the art machines. Our machines are tough, durable and dependable for flawless performance.

We Understand Your Needs

We manufacture a complete crushing solution tailored to the conditions of your site to ensure you have an effective operation.

One Stop Service, Help You from Start to End

From design through installation, we are with you every step of the way to fix any problems as they arise, saving you the hassle and the expense.

We Provide Value for Money to Make You Profitable.

We are using the highest quality equipment, solutions and service to increase production for you to make more money. That is a money well spent!

Various Crushing Host Adaptation

Mobile Concrete Crusher can freely switch between Impact Crusher/Cone Crusher/Jaw Crusher |VSI Crusher, etc. Construction waste & mining crushing are fully adapted to.

Has a robust and tough design for coarse crushing, so it is well suited to handling large concrete block, effectively primary crushing.

Has a very strong working principle for medium and fine crushing, a low wear-design, best suited for fine crushing high-hardness concrete.

Uses impact crushing, producing fine-grain finished product eg. high efficiency, suitable for recycling aggregate.

Characteristics offer sand shaping, controllable particle shape, suitable to produce high-quality concrete aggregate.

Mobile Concrete Crusher Cases

We are based in China and we produce Mobile Concrete Crushers for use in many projects of all varieties. After more than ten years of R&D and production, we’ve completed thousands of projects, provided thousands of solutions, and managed projects in a variety of industries including urban renewal, highway upgrades, and mining.

Testimonials

Yes! Sandreck’s integrated Concrete Crushing Plant will separate rebar automatically, using magnets and rebar shears.

A daily 10-point inspection (we provide a check-list), plus quarterly service intervals. Sandreck also has a full range of genuine spare parts for our Mobile Concrete Crushers.

To users, Mobile Concrete Crushing Equipment is a long-term investment and will obviously save you a lot of transport and waste disposal costs, and in a market where its value is very good. Please contact us for pricing information.

No, it is not difficult at all. The equipment is designed to be pragmatic and simple to get started. The user interface is quite clear! Sandreck are Mobile Concrete Crushers suppliers, and we will also provide on-site training for our supplied technicians.

Related Products

Fixed Crushing Plants VS Mobile Crushers:Capacity and Efficiency

1. Fixed Crushing Plants: Large-Scale Stable Output

• Automation Level: Fully automated whole-process operations (raw material → crushing → screening → finished product).

• Daily Capacity: Small plants: 500-1000 t/s; large plants: over 5000 t/s.

• Operation Mode: Supports 24/7 continuous operation, suitable for scenarios with stable long-term orders.

2. Mobile Crushers: Medium-to-Small-Scale Flexible Adaptation

• Capacity Limitation: Constrained by equipment size and integration; daily capacity ranges from 100-500 t/s.

• Key Advantage: Fits the “on-demand production” model, effectively avoiding equipment idleness during project gaps.

• Suitable Scenarios: Projects with limited processing volume or scattered operation locations.

Applicable Scenarios: “Long-Term Bases” vs. “Mobile Operations”

1. Fixed Crushing Plants: For Long-Term, Fixed Planning

Ideal Conditions:

• Projects with a cycle of 10+ years (e.g., long-term mine operation).

• Fixed production bases supplying stable clients (e.g., a plant in a building material area supplying concrete mixing plants long-term).

Core Value: Maximizes high capacity and scale benefits via “fixed customer base + fixed site.”

2. Mobile Crushers: For Scattered, Changing Projects

Ideal Conditions:

• Businesses with frequent site changes (e.g., construction waste recycling companies following demolition projects).

• Small-scale mining in mountainous areas (multiple small mines with limited reserves; building fixed plants is uneconomical).

Core Value: Adapts to changing sites and avoids waste from idle fixed equipment.

Fixed Crushing Plants VS Mobile Crushers: Three-Part Cost Structure

1. Fixed Crushing Plants: Three-Part Cost Structure

• Equipment Cost: Lower unit price compared to mobile crushers.

• Infrastructure & Supporting Cost: Accounts for 30%-50% of total investment (foundations, workshops, etc.).

• Long-Term Cost: Relatively low maintenance costs, but expansion/relocation = new investment.

2. Mobile Crushers: Equipment-Focused Cost Structure

• Equipment Cost: Price of an integrated mobile crushing plant is 2-3 times that of fixed production line equipment with the same capacity.

• Long-Term Cost: Slightly higher maintenance costs (due to high integration), but no infrastructure or long-term site rental fees.

• Key Advantage: Total early-stage investment is more controllable; no relocation costs.