Box Crusher

Box Crushers have the unique ability to efficiently crush oversized stones.

- Feed particle size:≤ 800MM

- Motor power: 55-380 KW

- Output: 10-480 T/H

Your Expert Box Crusher Supplier In China

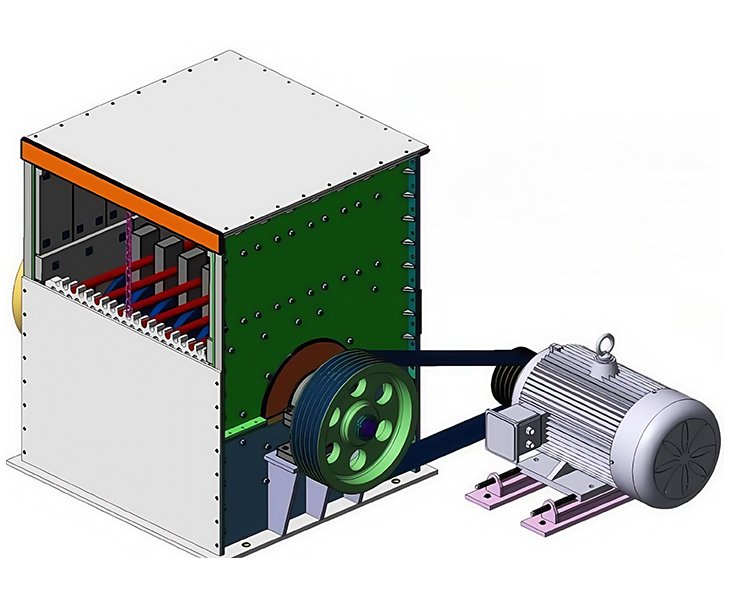

Sandreck box crusher is a heavy-duty industrial crushing equipment that integrates heavy hammer, impact and vertical shaft crushing technologies.

It is designed for efficient processing of hard materials such as ore, rock, construction waste, etc., and meets the continuous crushing needs in mining, renewable resource recycling, aggregate production and other fields. Its innovative hammer design can crush 450-800 mm materials to less than 80 mm at one time, thus saving multiple crushing processes and reducing energy consumption by 30%.

Sandreck box crusher adopts modular hammer design, which can quickly replace wearing parts, saving 50% of working hours than before, and the fully hydraulic unpacking system makes daily maintenance easier. It is especially suitable for continuous ore crushing production lines in chemical, metallurgical, building materials and other industries to ensure “zero delay in crushing”

Box Crusher Advantages

Box Crusher can replace the coarse and fine jaw, which can effectively reduce the investment.

Our Box Crusher uses advanced European crushing technology for energy saving.

Sandreck Box Crusher adopts automatic control system for easy operation.

Low noise, low dust emission, met the environmental protection standards.

Different needs, different models and sizes, we can all make customized.

Made of manganese steel structure with good quality guarantee, ensure stable operation.

Range of Box Crusher Applications

Box Crusher is used in mining crushing, construction waste recycling, chemical raw material processing and other industries. Suitable for medium hard materials (limestone, gypsum, dolomite, etc.). Also suitable for hard materials (granite, basalt, quartz, etc.).

Strength Factory

Sandreck works in the field of Box Crusher production for over 20 years and has professional technical team, which can provide technical support according to your requirement.

Box Crusher Cases

Sandreck is a well-known Chinese integrated supplier of crushed stone equipment and solutions, and has provided services for over a thousand sand and gravel processing plants.

Processing material: Sandstone

Capacity: 50-150t/h

Finished product size: 0-50mm

Host Products:XS1210 Box Crusher

Processing material: Limestone

Capacity: 120-300t/h

Finished product size: <80mm

Host Products:XS1614 Box Crusher

Technical Parameters

- Box Crusher

| Model | Maximum Feed size (mm) | Discharge Port Adjustment Range(mm) | Yield (t/h) | Equipped With Motor Power (kw) | Overall Dimensions (length x width x height) (mm) | Feed Port size (mm) | Weight (t) |

| XS0850 | 500 | 0-100 | 10-80 | 55 | 1278x1700x1685 | 850×655 | 4.5 |

| XS0910 | 500 | 0-100 | 15-100 | 55-75 | 1428x1838x1850 | 920×670 | 5.1 |

| XS1010 | 600 | 0-100 | 20-120 | 75 | 1428x1838x1850 | 1020×670 | 5.5 |

| XS1011 | 700 | 0-100 | 20-150 | 75-90 | 1578x1950x2028 | 1020×780 | 6.5 |

| XS1210 | 600 | 0-100 | 30-160 | 75-90 | 1428x2140x1850 | 1220×670 | 6.5 |

| XS1211 | 700 | 0-100 | 30-180 | 90-110 | 1578x2138x2028 | 1220×780 | 7.5 |

| XS1212 | 700 | 0-100 | 30-200 | 110 | 1632x2140x2186 | 1220×800 | 8 |

| XS1312 | 700 | 0-100 | 40-220 | 110-132 | 1632x2240x2186 | 1320×800 | 9 |

| XS1412 | 700 | 0-100 | 40-240 | 132-160 | 1632x2340x2186 | 1420×800 | 10.5 |

| XS1413 | 800 | 0-100 | 45-260 | 75×2 | 1940x2400x2480 | 1420×1000 | 14 |

| XS1414 | 800 | 0-100 | 45-260 | 90×2 | 1990x2372x2600 | 1420×1030 | 14.5 |

| XS1614 | 900 | 0-100 | 45-350 | 90-100×2 | 1990x2572x2600 | 1620×1030 | 15 |

| XS1814 | 900 | 0-100 | 45-380 | 110-132×2 | 1990x2772x2600 | 1820×1030 | 16.5 |

| XS1616Z | 1000 | 0-100 | 50-400 | 132×2 | 2360x2780x2955 | 1620×1150 | 21 |

| XS1816Z | 1100 | 0-100 | 50-450 | 160×2 | 2360x2980x2955 | 1820×1150 | 26 |

| XS2016Z | 1000 | 0-100 | 50-500 | 200×2 | 2360x3200x2955 | 2020×1150 | 28 |

Testimonials

The hammer head is generally replaced in about 2 months and the liner is replaced in 8 months. Please consult us for specific circumstances.

For the maintenance of the mill, we need to: control the feed particle size, avoid overload and foreign matter.

We are the source factory of crushers in China. For the ex-factory price of each crusher, you can leave a message via WhatsApp (+8613666293477), and we will contact you ASAP.

Related Product

Used for grading and screening of minerals, quarries, building materials, etc.

The crushing ratio is large and the feed particle size can reach 100mm.

Linear feeding equipment that continuously feeds materials into the crusher.