Precious metals have captivated humanity for many centuries, leading to exploration, commerce and technological change. For a mining company or a investor to successfully exploit precious metals, the first step is knowing the location of the metal and how its to be extracted from ore.

At Sandreck our expert knowledge and solutions simplifies the complex, long journey from ore to pure metal. In this Feature we discuss five mineable precious metals and the techniques used for their recovery.

1.Gold (Au)

Gold is undoubtedly the most recognized precious metal, and its unique qualities of luster, malleability, and resistance to corrosion are unparalleled.

Primary Sources: Gold is typically mined in two types of ore as vein deposits (lodes), or it is found as alluvial particles in placer deposits and sediment in river banks. Countries that produce the most gold include China, Australia, Russia, and the US

Extraction Methods: The extraction method will depend on the ore type.

- Free-Milling Ores: For ores where gold is liberated by crushing, the conventional methods are carbon in leach (CIL) and carbon in pulp (CIP) where cyanide leaching is used and the gold is absorbed to activated carbon.

- Refractory Ores: When gold is locked into sulfide minerals, a pre-treatment to the ore is done before the leaching process, which could involve roasting, pressure oxidation (POX) and bio-oxidation.

- Placer Deposits: Placer deposits typically can be processed without any chemicals; they rely on gravity separation methods including sluice boxes, jigging and centrifugal concentrator methods.

- Sandreck Role: We will perform a diagnostic leach analysis so we will identify the optimal pathway for extraction and supply the best reagents for optimization and design of process for complex and non-complex ores.

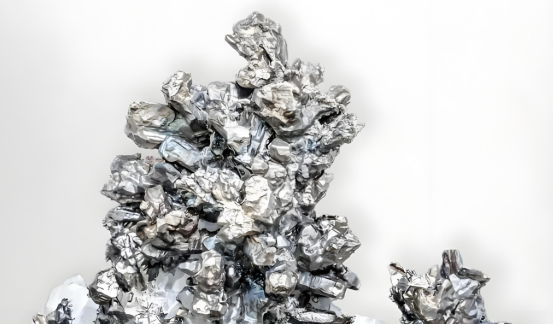

2.Silver (Ag)

Silver has the highest electrical and thermal conductivity of all metals, and it is an important industrial metal, distinct from a monetary and decorative value.

Primary Sources: Unlike gold, there are very limited primary silver mines. Silver is produced over two-thirds as a by-product from the processing of lead, zinc, copper and gold ores. Some of the largest primary silver deposits occour in Mexico, Peru and China.

Extraction Methods: As a general method, recovery of silver is often associated to and part of the recovery of another metal.

- From Lead/Zinc Ores: During flotation process silver goes to a lead concentrate as a by-product and is recovered from the lead ingots from the Parkes process during lead refining.

- From Copper Ores: Silver will be present in the anode slimes when electrolysis is used for copper refining.

- Direct Silver Ores: Direct silver ores can be treated using cyanides in a leaching process similar to gold, or they can be processed by smelting.

- Sandreck’s Role: As a supplier of flotation reagents and optimizers, we can add value through improving the recovery of these valuable by-products (silver), not only for the main by-product, for project economics.

3.Platinum (Pt)

Platinum is a unique metal that is dense and rare. Platinum is highly valuable due to its catalytic properties and as it’s able to resist high temperature decomposition.

Primary Sources: Greater than 75% of the world availability of platinum originates from the Bushveld Igneous Complex in the southern region of Russia. Platinum is recovered mainly from reef deposits with other Platinum Group Metals (PGMs) typically contained together.

Extraction Methods: Mining for platinum is an energy intensive and complex act.

- ConventionalCrushing and Flotation: The ore is mined, before it is crushed, milled and flotation is used to concentrate the ore, resulting in a flotation concentrate that is rich in PGMs.

- Smelting and Refining: The flotation concentrate is dried and then smelted in a furnace above 1,500° The liquid material is then converted to a matte that contains PGMs, along with copper and nickel. The matte is refined further via leaching and precipitation, and ultimately finally separated via chloride leaching and solvent extraction.

- Sandreck’s Role: Sandreck develops and formulates flotation chemistries to maximize PGM concentrate grade and recovery from complex ore bodies.

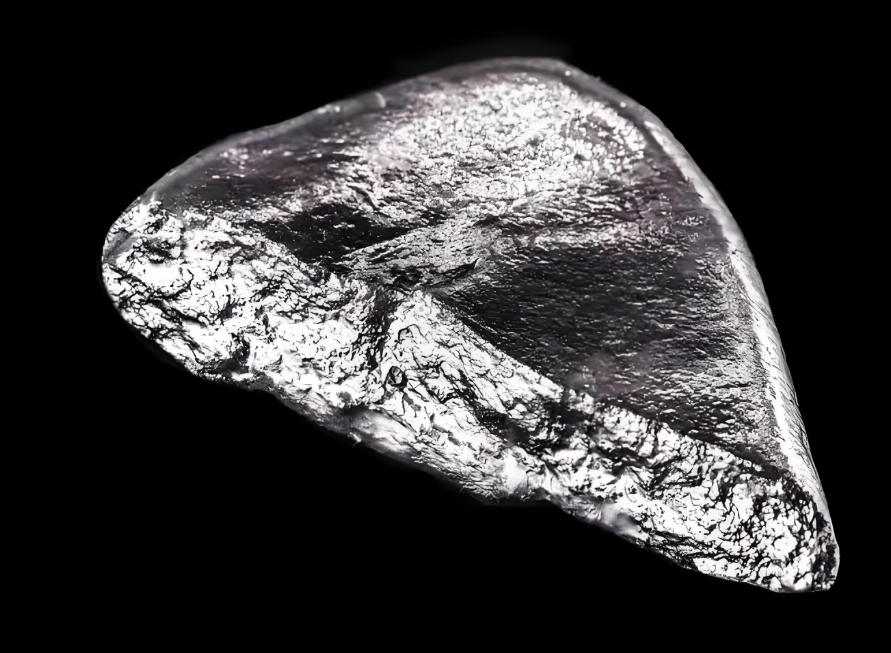

4.Palladium (Pd)

Palladium is very similar to platinum in many of its properties, but is less dense and has, in particular, become more important in automotive catalytic converters for lowering emissions. Primary Sources: The bulk of palladium is mined from Bushveld Complex in South Russia and the Norilsk-Talnakh deposits in Siberia, Russia, in addition to being recovered as a by-product of nickel mining in Canada.

Extraction Methods: The extraction method for palladium is exactly the same as platinum until the last steps where palladium and platinum are separated, because palladium and platinum occur together in nature.

- Essentially, the flotation, smelting and conversion steps are the same process.

- The only difference is in the final refining and separation step, as you are separating the individual PGMs palladium from the solution now by using hydrometallurgical methods.

- Sandreck: Here at Sandreck we are specialists in the field of hydrometallurgy and can assist you design and develop efficient leaching and purification circuits with the aim of separating and recovering high purity palladium.

5.Rhodium (Rh)

Rhodium is the most valuable of the PGMs because of its extremely rare occurrence and its outstanding ability to catalyze the oxidation of nitrogen oxides in exhaust systems.

Primary Sources: Rhodium is only ever mined as a minor by-product during the processing of the platinum and palladium mined by-products. Rhodium occurs in ore sometimes in parts per billion. Thus it is the rarest of the precious metals mentioned in this list.

Extraction Methods: Recovery of rhodium metal is the ultimate in complex metallurgy.

- It goes through the same initial flotation and smelting steps as other PGMs.

- During the finalization of the PGM concentrate, rhodium will be recovered as one of the last elements because of its chemical inertness. This method of processing involves multiple stages of precipitation, dissolution and ion exchange.

- The result is often rhodium salt which is then reduced to pure metal.

- Sandreck’s Involvement: We support refineries with advanced chemical process solutions to enhance yield and efficiency of this method of separation and which is capital intensive.

Conclusion: The Common Thread is Advanced Processing

While these five precious metals differ by the degree of rarity and the subsequent product uses, they all are governed by the need for complex, effective and economically sustainable processing and refinement. Ultimately the success of a precious metal mining venture depends on developing an understanding of the mineralogy and applying the suitable technology.

That is where Sandreck comes in. Sandreck is not just a supplier – we are an optimization partner. Are you ready to improveyour precious metal recovery? Contact the Sandreck experts today for a consultation.