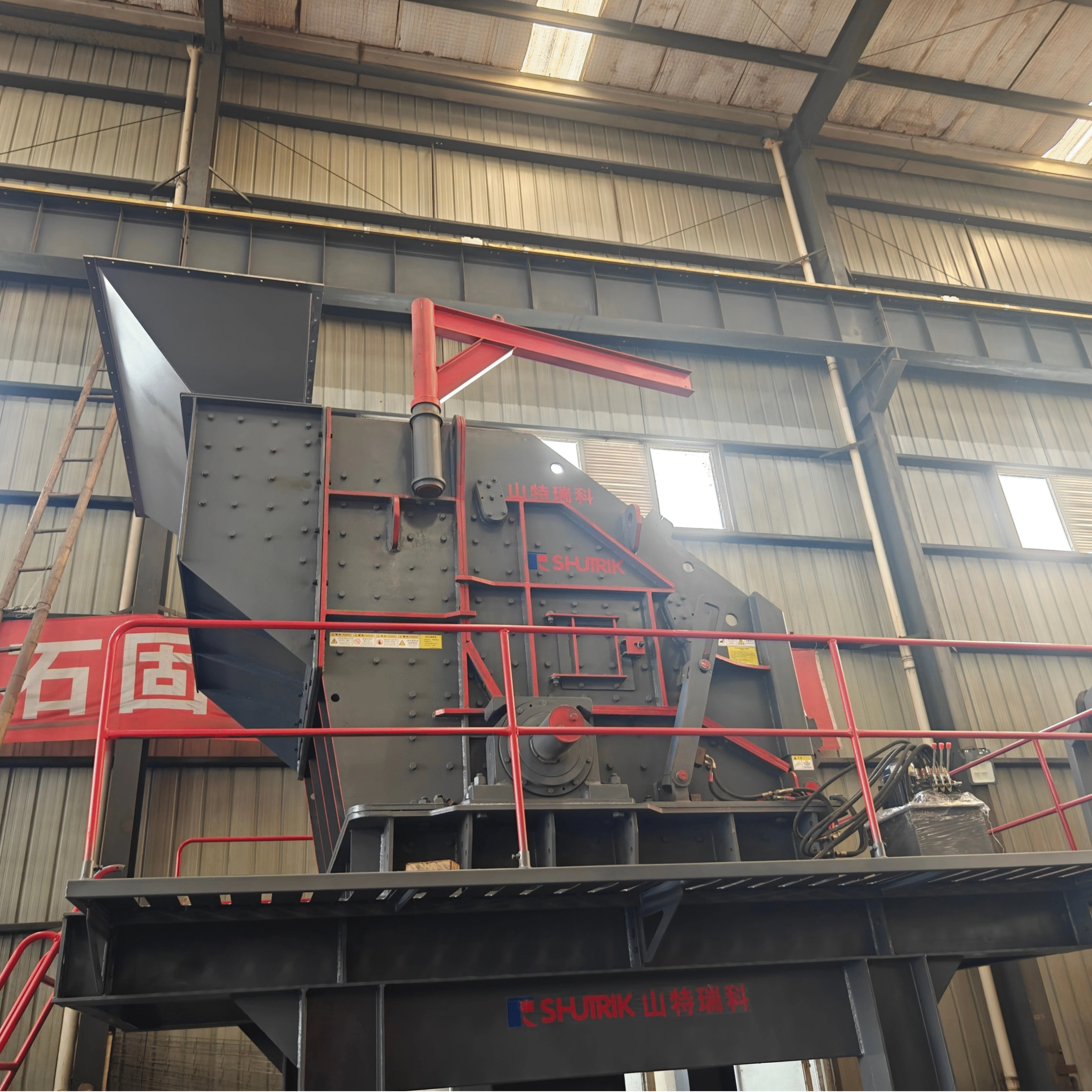

Impact Crusher

The Impact Crusher is a versatile crushing machine that uses high-speed impact force to break down materials into smaller, uniform sizes.

![]() Easy to install and maintain, with fewer wear parts compared to Cone Crushers.

Easy to install and maintain, with fewer wear parts compared to Cone Crushers.

![]() Efficiently crushes materials with a single rotor or hammer system, producing finer output.

Efficiently crushes materials with a single rotor or hammer system, producing finer output.

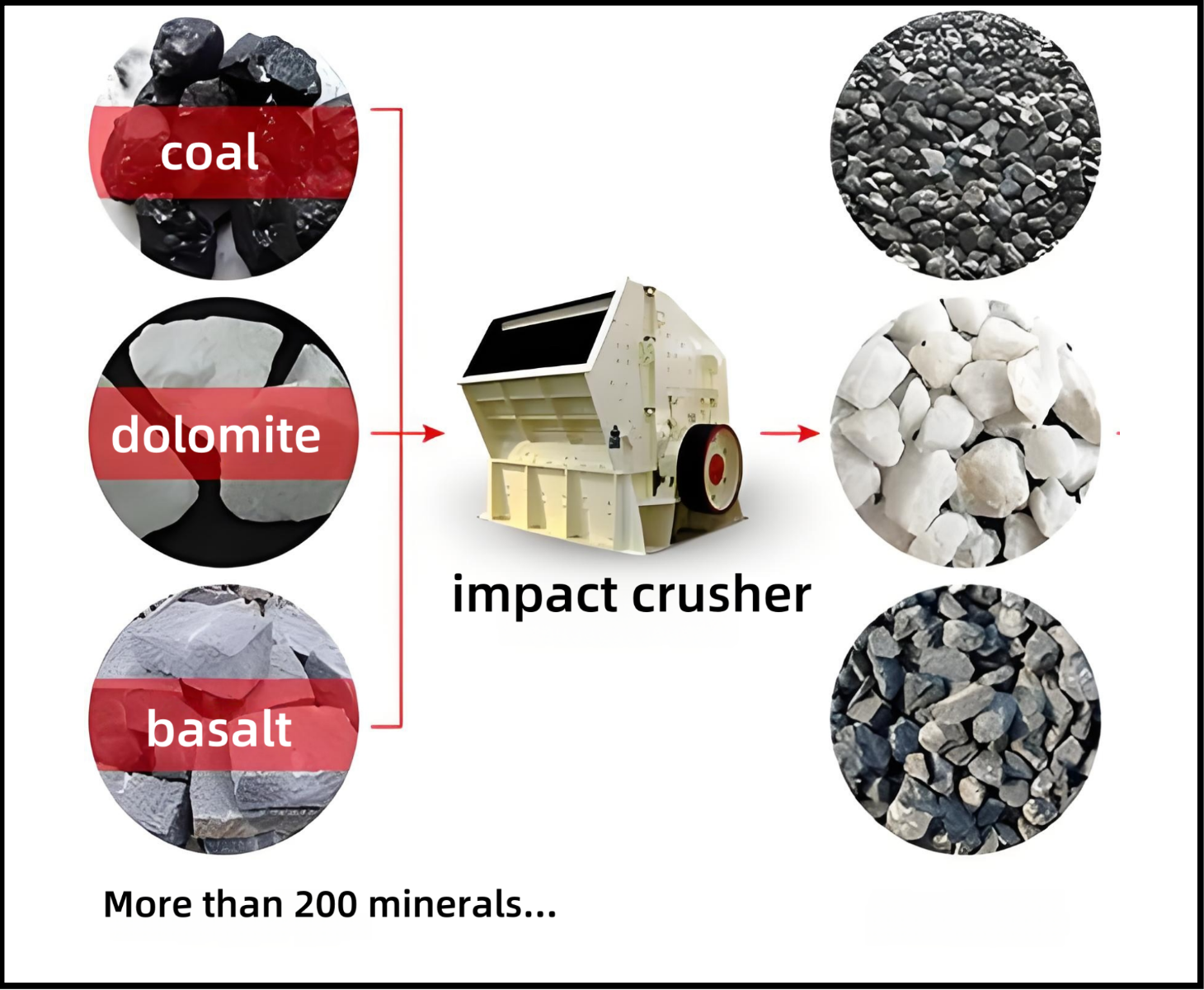

![]() Suitable for both soft and medium-hard materials like limestone, concrete, and recycled aggregates.

Suitable for both soft and medium-hard materials like limestone, concrete, and recycled aggregates.

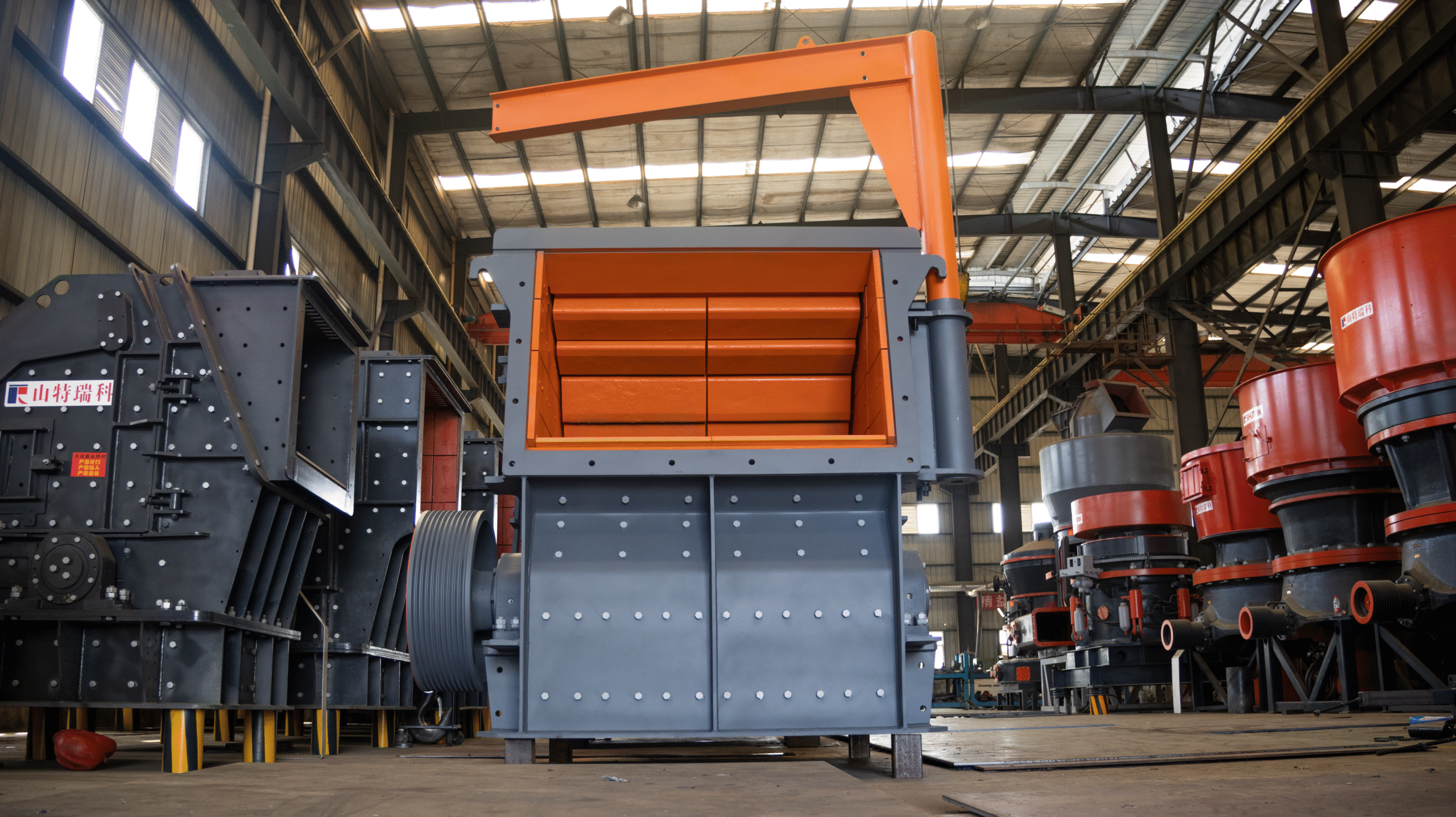

Your Expert Impact Crusher Supplier In China.

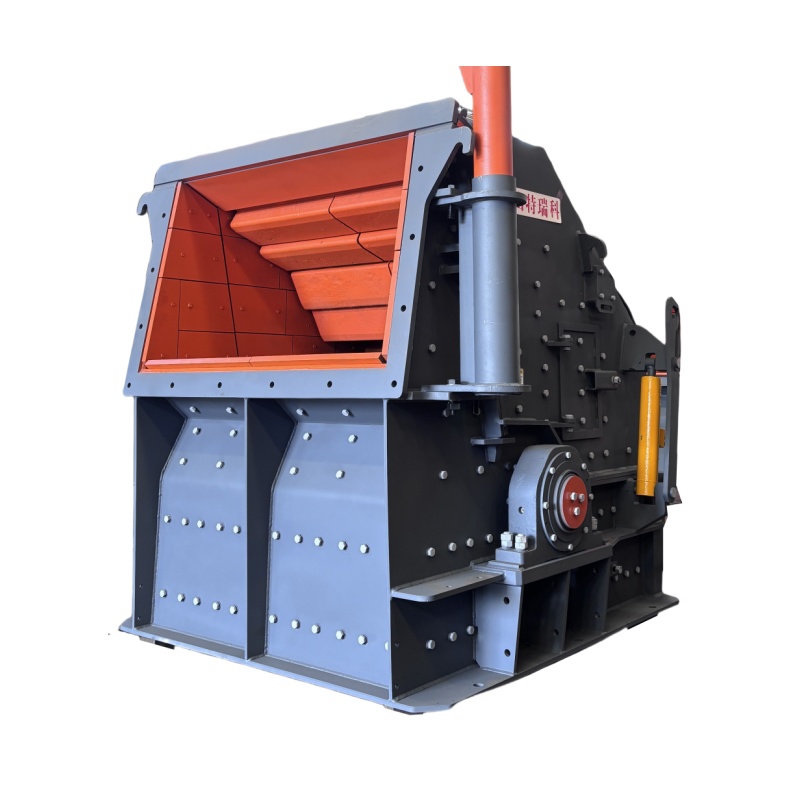

Sandreck Impact Crusher use high-speed lined rotors to break materials through impact. Suitable for primary, secondary and tertiary crushing, can efficiently process quarry rock, concrete and construction waste.

Sandreck Impact Crusher are designed with high reduction ratios to produce fine finished particle size, which is essential for aggregate and industrial applications. Their rugged construction ensures durability in harsh conditions. Features such as adjustable liners and hydraulic assist provide precise control of output particle size and grading.

Sandreck is a Impact Crusher manufacturer in China, which offers a comprehensive product range, including PFW and C series models, all of which are ISO9001 certified and quality guaranteed. Choose Sandreck Impact Crusher for adjustable, high-capacity crushing. Our global service network ensures reliable operation of your project and peace of mind.

Product By Features

Sandreck PF Impact Crusher use an integral cast steel bearing structure to save you maintenance and operating costs.

Sandreck C series Impact Crusher break the Max feed size up to 1000mm, can achieve coarse crushing and medium crushing conversion.

PFW Impact Crusher

PFW Impact CrusherPFW Euro Impact Crusher is a high efficient and energy saving crushing equipment, ideal for construction waste.

Impact Crusher Advantages

The rotor has high strength and strong impact crushing force, which is suitable for crushing large materials.

The full hydraulic system is adopted, which is convenient for replacing accessories and maintenance.

The optimized crushing chamber reduces downtime and improves crushing efficiency by 20%.

Particle size conversion can be achieved by adjusting the impact frame, which simplifies the crushing process.

Sandreck Impact Crusher uses highly wear-resistant materials, with less wear, saving you investment costs.

Our production process is clear and transparent to ensure stable and reliable equipment quality.

Impact Crusher: Crushes It All Rocks

Sandreck Impact Crusher are used by customers all over the world. Whether you are processing soft materials such as limestone, coal, coke or hard materials such as basalt, iron ore, marble, we have rich configuration experience. Suitable for sand and gravel aggregate production, cement processing, construction waste, etc.

Prevent Entanglement With Steel Bars

The Sandreck Impact Crusher’s rotor features a heavy-duty design, increasing its moment of inertia and impact crushing capacity, while also effectively preventing steel bars from becoming entangled when crushing construction waste.

Customized Impact Crushing Solutions for You

We don’t just sell equipment; we also design crushing solutions tailored to your site’s needs.

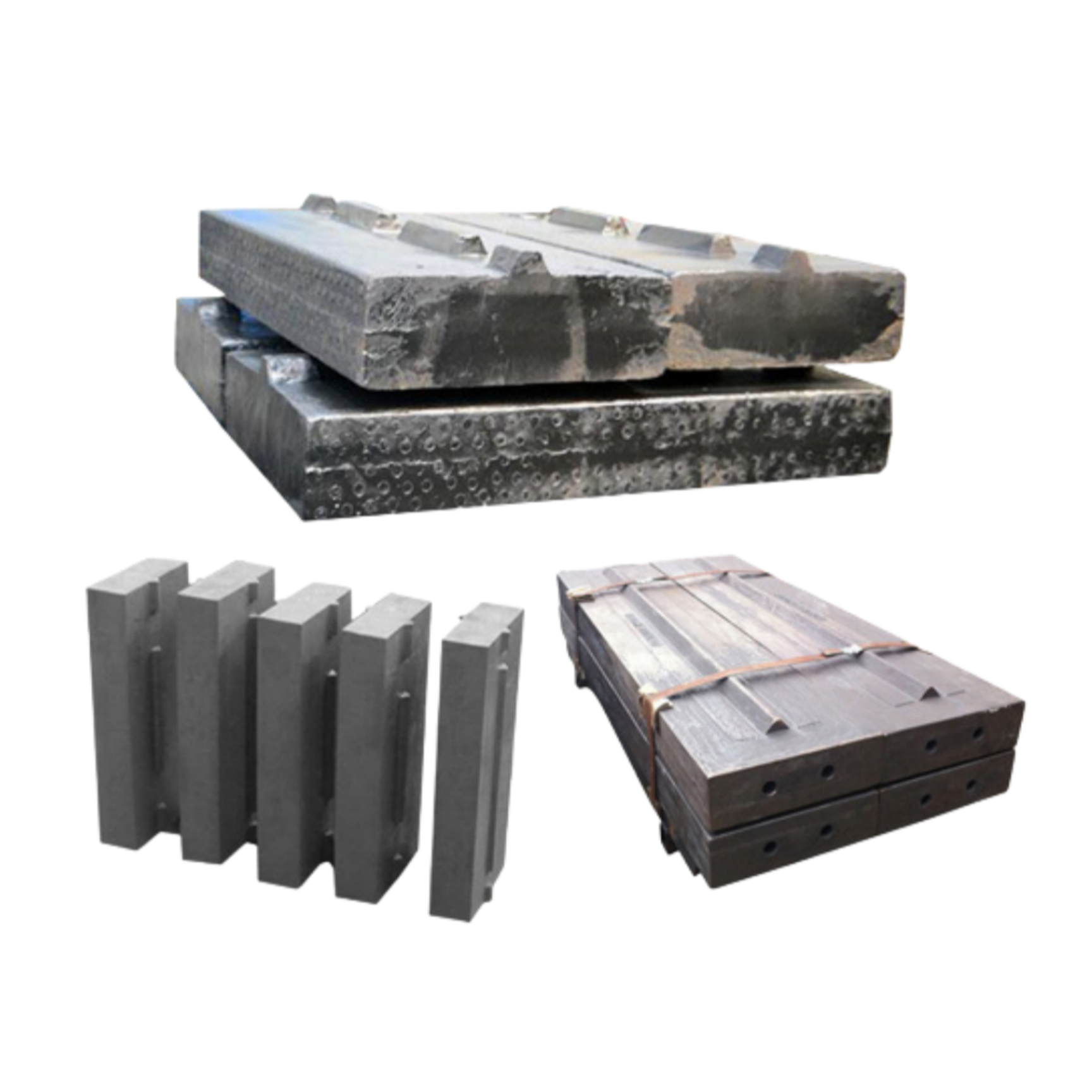

Cone Crusher Parts

Sandreck Impact Crushers are designed to consolidate a primary/secondary crushing operation into a single machine

The Impact Crushers feature a hydraulic cover opening operation which makes inspecting and changing components quicker

The Impact Crusher has wear parts (blow hammer, liner and impact plate) constructed from high-chromium alloy construction that can last 3-4 times longer than standard wear materials.

The Sandreck commitment to a full lifecycle of our equipment, from commissioning training to parts supply and rapid response service genuinely makes for worry-free production.

Impact Crusher Cases

As a well-known Chinese supplier specializing in integrated crushed stone equipment and solutions, Sandreck has provided services to more than 1,000 sand and gravel processing plants.

Processing material: Mountain Stone

Capacity: 100-200 t/h

Finished size: 12 stone, 13 stone, mechanism sand

Processing material: Basalt

Capacity: 100-200 t/h

Finished size: 12 stone, 13 stone, mechanism sand

Processing material: hillstone

Capacity: 100 t/h

Finished size: 12 stone, 13 stone, mechanism sand

Host: Impact Crusher

Capacity: 300 t/h

Finished size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

Testimonials

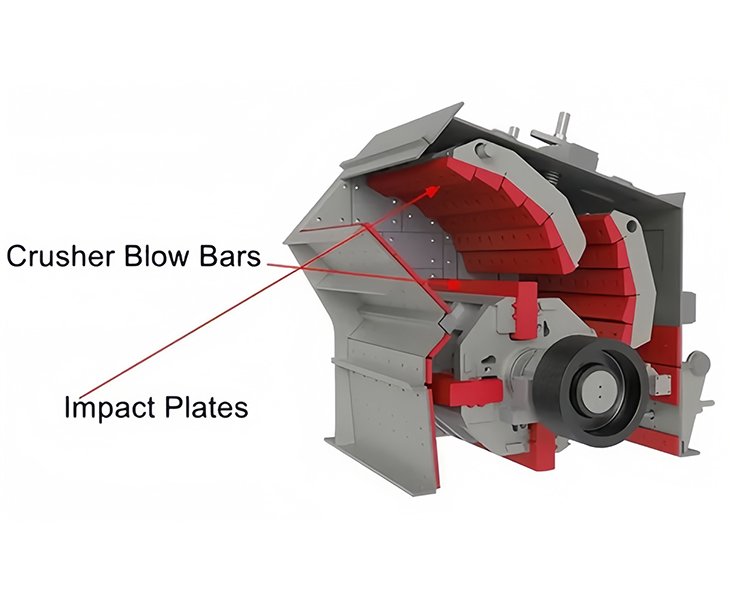

Sandreck Impact Crusher is mainly composed of plate hammer, lining plate, rotor, tie rod, counter frame, spindle and press block.

Check the lubrication system every 8 hours to ensure timely refueling of bearings; Regularly check the wear of the hammer and counterattack plate; Clean the residual materials in the crushing chamber.

Check the wear of rotor, plate hammer and counterattack plate; Clean the crushing chamber and sieve plate; Lubricate bearings and check tightness.

By adjusting the gap between the counter plate and the rotor, the smaller the gap, the finer the discharge, and then replace the screen plate of different specifications to control the final particle size.

Related Product

How Does an Impact Crusher Work?

The Two-Stage Crushing Process: Impact and Attrition

The operation of an Impact Crusher is a rapid, two-fold process that happens in milliseconds.

1.Primary Impact (The First Blow):

As large rocks enter the feed opening, they are met by the spinning blow bars on the rotor.

The blow bars strike the rocks, transferring a massive amount of kinetic energy.

This initial impact shatters the rocks and propels them violently towards the primary impact aprons.

2.Secondary Crushing (The Rock-on-Rock Anvil):

This is where the magic happens for product shape.

The material ricochets off the primary aprons and is thrown back into the path of the rotor.

On its return journey, it collides with other incoming rocks in a process known as “rock-on-rock” attrition.

This repeated, high-velocity collision between rocks further breaks them down and knocks off weak edges, creating the highly valued, well-shaped, cubical product that Impact Crushers are famous for.

Finally, smaller material that has reached the desired size passes through the gap between the rotor and aprons to be discharged………….