Stone Crusher Factory

The stone crusher is an essential piece of equipment in mining machinery, used for crushing various ores.

![]() It is divided into coarse crushing, medium crushing and fine crushing equipment.

It is divided into coarse crushing, medium crushing and fine crushing equipment.

![]() It provides high-quality sand and gravel aggregates for the construction industry.

It provides high-quality sand and gravel aggregates for the construction industry.

![]() It is used in the front-end crushing process in the mining field.

It is used in the front-end crushing process in the mining field.

Your Expert Stone Crusher Supplier in China

As a leading manufacturer of stone crushing equipment in China, Sandreck specializes in providing powerful solutions for all your sand and aggregate processing needs.

Whether you need primary crushing, secondary crushing or fine shaping, our equipment offers unrivaled durability and productivity.Our Rock Crushing Equipments for sale are widely used in concrete, quarrying and mining operations.

Whether you are dealing with soft materials (limestone, coal, coke, etc.) or hard materials (basalt, iron ore, marble, etc.), we have professional and suitable equipment.

Our product line includes Jaw Crushers, Cone Crushers, Impact Crushers and efficient Heavy Hammer Crushers to handle materials of varying hardness and size.

Product By Features

Sandreck Jaw Crusher is the first and primary choice for the coarse crushing.

Sandreck’S Stone Crusher Advantages

The optimized structural design of our Stone Crusher minimizes downtime and improves crushing efficiency.

Our production process is clear and transparent, and each process is strictly controlled.

Our Stone Crusher is used for coarse and medium crushing of stone in construction, metallurgy, mining, etc.

We have a professional team, and can ship within 25 working days after the contract is signed.

We have exported to more than 150 countries and regions, with more than 10 overseas branches.

Sandreck adheres to the principle of Customers First and provides after-sales service all year round.

Stone Crusher Machines - Your Reliable Partner in Aggregate Solutions

Sandreck Mining Machinery Co., Ltd. is a well-known supplier of stone crushing equipment and solutions. With over 20 years of engineering expertise, Sandreck ensures cost-effective, customized solutions backed by strict quality control. Combining advanced technology with reliable Chinese manufacturing, you can just trust us to optimize your quarry operations.

How To Choose The Right Stone Crusher?

If you do not know how to choose the right Stone Crusher, please inform us of your raw material characteristics, hourly output, finished product requirements, application scenarios, investment budget and other needs. Our professional engineers will be equipped with the right equipment according to your needs.

Company Advantage

Sandreck is one of the world’s leading manufacturers of stone crushing equipment, combining research & development, design & engineering, manufacturing, and sales. With an elaborate manufacturing infrastructure, the company employs more than one hundred working units of state-of-the-art machine tools such as CNC vertical lathes, deep-hole drilling machines, laser cutters, planers, and CNC boring and milling centres.

We have high-performance stone crushing solutions for our global customer base. We pride ourselves on cooperating with customers by developing custom systems or providing comprehensive technical support according to the best interest of the customer.

The goal is to ensure that systems function optimally to give our customers the best value at all times.

About Our Products

For your Stone Crusher, we stand by your side 24 hours a day, providing round-the-clock protection for your choices!

Design for tremendous force. Made from high-strength steel for maximum toughness and reliability, even under extreme stresses.

We manufacture our material from high-manganese steel, it provides a better wear resistance when discussing the most difficult applications such as granite and basalt.

Our installation experts and professionals take pride in ensuring that your equipment provides maximum stability, usable life, and operational efficiency from day one.

Our committed after-sales team offers quick turnaround support, expert maintenance and easy access to wear parts to ensure your equipment is performing at maximum efficiency.

Stone Crusher Cases

Sandreck is a well-known Chinese integrated supplier of crushed stone equipment and solutions, and has provided services for over a thousand sand and gravel processing plants.

Processing material: Limestone

Capacity: 100-200 t/h

Finished size: 12 stone, 13 stone, mechanism sand

Processing material: Granite

Capacity: 200 t/h

Finished size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

Processing material: Limestone

Capacity: 800 t/h

Finished size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

Processing material: Pebble

Capacity: 400 t/h

Finished size: 12 stone, 13 stone, mechanism sand

Testimonials

First, cut off the power supply immediately and then check the problem. General problems include feed blockage, motor overload, and foreign matter stuck. If the above methods cannot solve the problem, please contact the manufacturer.

Regular lubrication, symmetrical replacement of wear parts, preventive inspection, and spare parts inventory.

Strictly abide by the standard maximum feed size of the equipment; pre-screen the material; feed evenly to prevent the crusher from overloading or idling.

Different models of Stone Crusher have different prices, and the price is generally more than US$3,000 (for reference only). To know the specific price of the crusher, please contact us via WhatsApp (+8613666293477).

Related Product

Sandreck LVM Ultrafine Vertical Mill is a high efficiency machine, and make one-time grinding.

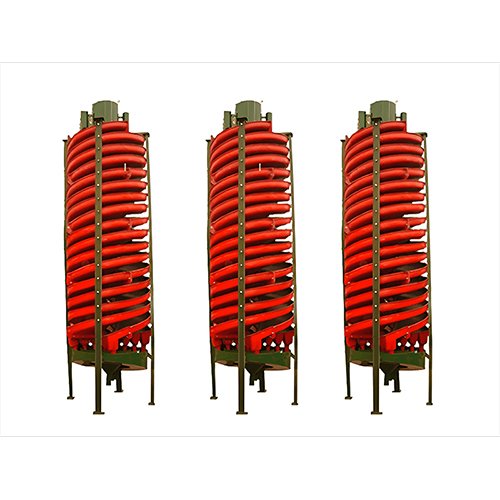

Sandreck Spiral Chute is an efficient separation equipment for fine-grained minerals with a high quality.

Sandreck can provide good quality of concentrate begins with good flotation.

Linear feeding equipment that continuously feeds materials into the crusher.