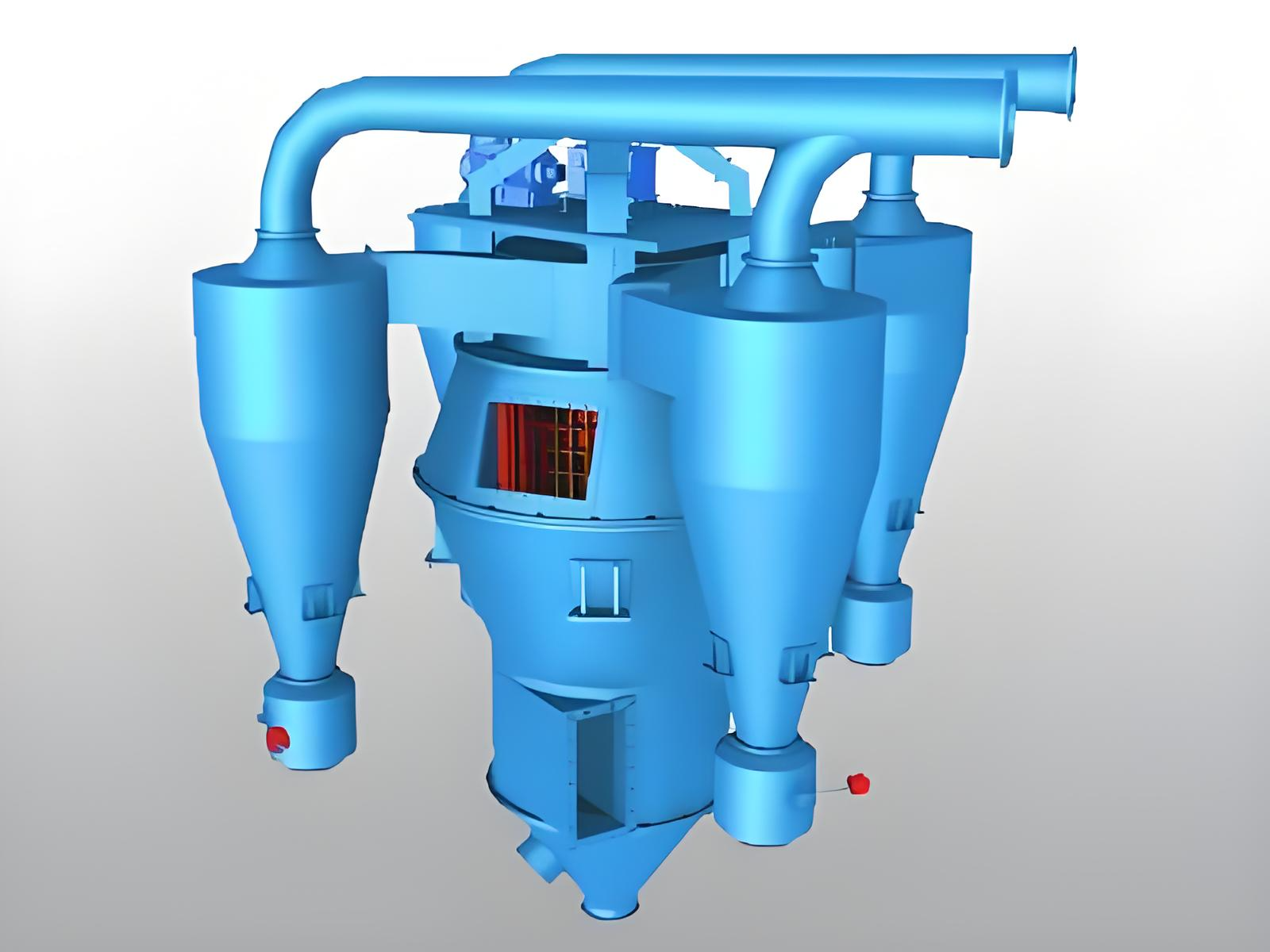

SRM Vertical Grinding Mill

SRM vertical grinding mill is an important equipment for the non-metallic mineral ultra-fine grinding in the mining and metallurgical industry.

- Feed Size: 5-55MM

- Capacity: 2-25T/H

- Particle size: 8-325mesh

Your Expert SRM Vertical Grinding Mill Supplier in China

Sandreck is a source Grinding Mill supplier in China, the SRM Vertical Grinding Mill we produced is a state-of-the-art mineral grinding machine, our company has created by integrating advanced technologies from both domestic and international sources, with continuous improvements. It boasts centralized processing, a streamlined design, low investment costs, high efficiency, energy savings, and eco-friendliness.

Sandreck SRM Vertical Grinding Mill is a mining sand and gravel grinding factory with relatively mature technology and good performance. It has drying, powder making and powder selection functions, and can grind block, granular and powdery materials into fine powder.

SRM Vertical Grinding Mill Advantage

The equipment adopts an integrated design, including fine crushing, drying, grinding, and powder selection.

SRM Vertical Grinding Mill can handle special materials such as high humidity and high hardness.

We carefully select equipment to ensure low maintenance costs and long service life.

Equipped with an electric dust removal system to ensure compliance with environmental regulations.

It can adjust the product particle size and can produce finished products from 8 mesh to 325 mesh.

SRM Vertical Grinding Mill has a PLC one-button control system, which can be remotely controlled.

Highly Wear-Resistant Grinding Rolls And Discs

Sandreck Vertical Grinding Mills employ a special high-chromium alloy + ceramic composite wear-resistant material that surpass HRC63 hardness, providing double wear-resistance and increasing service life to save you over 40% savings in the cost for component replacement.

Ultra-High Precision Classifier

The Vertical Grinding Mills we offer come with a height adjustable speed classifying system. This means you can adjust the fineness of the grinds to depths between 80-350 mesh. This gives you a great deal of flexibility as you adapt your production needs. The end product has a uniform particle size with a high pass rate, which has helped to eliminate customer complaints/returns related to quality.

Efficient Drying, Multi-Purpose Machine

Sandreck Vertical Mills have a drying system incorporated into the machine that can grind and dry at the same time, while simultaneously and easily processing high moisture materials (moisture content >15%.) and delivering the dried material (moisture content ≤1%.) to eliminate the need for a drying machine separately, save space, and save you on electricity costs.

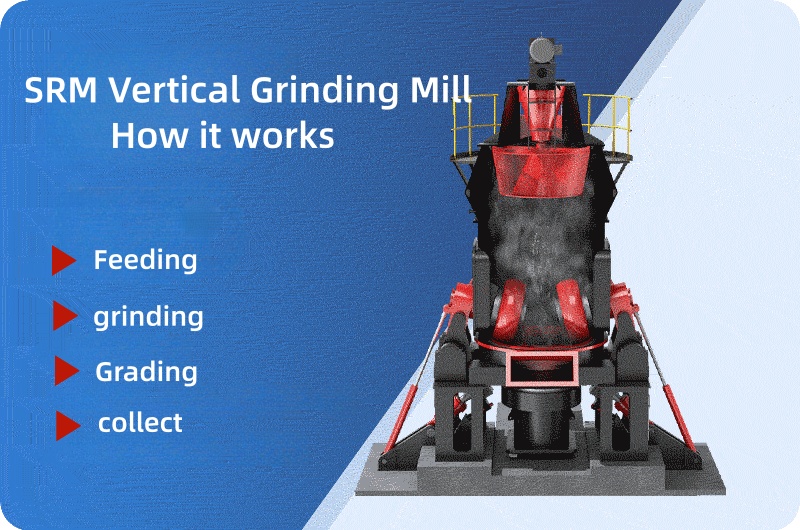

How does a Vertical Grinding Mill Work?

Sandreck’s Vertical Grinding Mills combine grinding, drying, and classifying in one machine. They are highly efficient and energy-efficient, and can handle materials with high moisture content.

Material feeding and spreading:

Mineral particles are uniformly fed to the center of the vertical mill’s grinding disk. The grinding disk incorporates a motor at the bottom, causing it to rotate at a high peripheral speed while centrifugal force pushes the material toward the outer edge of the disk.

Main grinding:

The grinding rollers exert a downward hydraulic pressure to the material at the mill’s disk edge, grinding the material in thin layers to pulverized fine powder.

Classifying and fineness control:

The fine powder is moved by a hot air flow from below and enters the classifier. Adjusting the classifier’s revolution speed or blade angle controls powder fineness. Qualified fine powder enters the system/collection silo while unqualified particles fall back onto the grinding disk.

Status of closed-circuit:

Unqualified particles are ground again, this take establishes the closed circuit status with inputting materials and makes finished products qualified and meets standards.

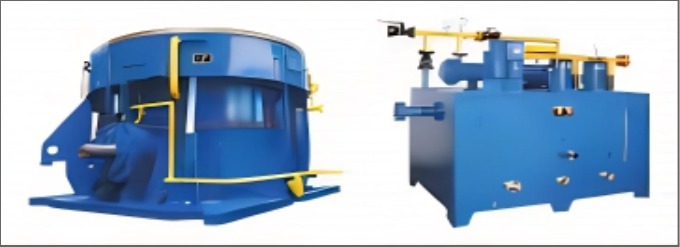

SRM Vertical Grinding Mill Details Picture

SRM Vertical Mill: Precision Classifier + Durable Grinding Rollers/Table + Smart Hydraulic System, paired with High-Torque Gearbox & Reinforced Housing – China’s 20+ Years Engineered Industrial Grinding Solution!

SRM Vertical Grinding Mill

- Technical Parameters

Specifications | SRM19- 2K | SRM22-2K | SRM24-2K | SRM27-2K | SRM27-3K | SRM31- 2K | SRM31-3K | SRM34- 2K | SRM34- 3K | SRM37- 3K | SRM39- 3K | SRM44- 4K | SRM50- 4K | |

| Yield(t/h) | 10~40 | 15~50 | 20~70 | 25~85 | 30-90 | 38~135 | 40~145 | 46~160 | 48~170 | 55~196 | 65~220 | 75~260 | 90~400 | |

| Maximum Feed Size(mm) | 30 | 30 | 35 | 35 | 35 | 45 | 45 | 45 | 50 | 50 | 50 | 50 | <55 | |

| Main Motor Power(KW) | 200 ~ 220 | 280 ~ 315 | 400 ~ 450 | 500 ~ 560 | 500 ~ 630 | 630 ~ 900 | 710 ~ 1000 | 800 ~ 1120 | 800 ~ 1250 | 900 ~ 1600 | 1120 ~ 1800 | 1800 ~ 2200 | 2500 ~ 3150 | |

| Optimal Water Content in Grinding | <4% | <4% | <4% | <4% | <4% | <4% | <4% | <4% | <4% | <4% | <4% | <4% | <4% | |

| The Moisture Content of The Material to Be Dried | <15% | <15% | <15% | <15% | <15% | <15% | <15% | <15% | <15% | <15% | <15% | <15% | <15% | |

| Finished Product Fineness | μm | 840-37 | 840-37 | 840-37 | 840-37 | 840-37 | 840-37 | 840-37 | 840-37 | 840-37 | 840-37 | 840-37 | 840-37 | 840-37 |

| mesh | 20-400 | 20-400 | 20-400 | 20-400 | 20-400 | 20-400 | 20-400 | 20-400 | 20-400 | 20-400 | 20-400 | 20-400 | 20-400 | |

| Finished Product Moisture(drying) | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | |

Testimonials

Check the wearing parts and lubrication system frequently and make sure the properties of the material reach the requirement; control the air inlet temperature and air volume and prohibit overload operation.

Generally, the SRM Vertical Grinding Mill spare parts need replacement every 6-12 months depending on usage and hardness of material.

You can leave us a message via WhatsApp(+8613666293477) or click on the dialog box at the bottom right corner., we are a Chinese grinding mill factory, each of our equipment is ex-factory price.