Spiral Chute

Sandreck Spiral Chute, is the best equipment for mining and beneficiation, has the advantages of small area, less water consumption, simple structure, easy operation, etc.

- Tungsten/tin ore roughing and concentrating

- Iron ore roughing and concentrating

- Gold tailings re-selection

- Quartz sand iron removal

What Is Spiral Chute?

Sandreck Spiral Chute is a sand and gravel re-selection equipment used in the mining industry. In addition to simple operation, Sandreck Spiral Chute also has a good processing effect, such as stable ore dressing, clear ore separation, large processing capacity, high efficiency and high ore dressing enrichment ratio.

Sandreck Spiral Chute Advantages

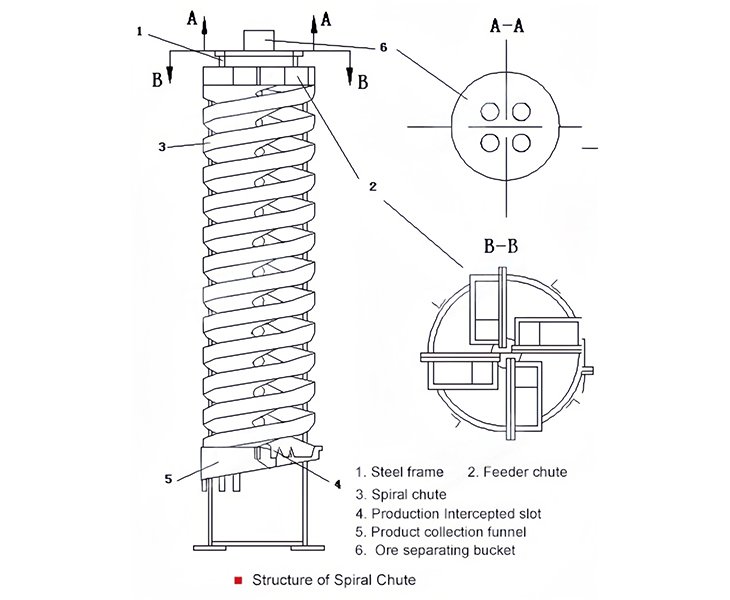

Sandreck Spiral Chute adopts imported fiberglass skeleton + advanced technology, and its acid and alkali corrosion resistance is improved by 3 times.

The integrated intelligent tailings system of Sandreck Spiral Chute improves work efficiency while the concentrate recovery rate reaches more than 20%.

The slurry flow and flow velocity of Sandreck Spiral Chute is dynamically balanced to ensure the stability of the sorting process and the fluctuation rate is less than 5%.

The spiral of Sandreck Spiral Chute trough cross-section adopts fluid simulation to generate a short surface to achieve an efficient sorting surface.

The pre-selection and selection of Sandreck Spiral Chute dual modules can be customized according to the different types of ore required.

Sandreck Spiral Chute takes up little space, does not require a complex control system, and can be operated with one machine, reducing energy consumption by 25%.

Why choose Sandreck Spiral Chute?

Sandreck is a professional manufacturer and supplier of mining sand and gravel equipment in China, Sandreck currently has a variety of good quality and low price spiral chutes for sale. Sandreck Spiral Chute is your first choice to choose.

More About Our Company

- Technical Parameters

Model | BLL-2000 | BLL-1500 | BLL-1200 | BLL-900 | BLL-600 | BL-400 | |

| Spiral Outer Diameter (mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 | |

| Pitch(mm) | 1200 | 900,675 | 900,720,540 | 675,540,405 | 450,360,270 | 240,180 | |

| Pitch to Diameter Ratio (pitch/diameter) | 0.6 | 0.48,036 | 0.75,0.6,0.45 | 0.75,0.6,0.45 | 0.75,0.6,0.45 | 0.6,0.45 | |

| Lateral Inclination Angle (°) | 9° | 9° | 9° | 9° | 9° | 9° | |

| Number of Screw Heads Installed | 3 | 4 | 4 | 4 | 2 | 2 | |

| Feed Size(mm) | 2.00-0.04 | 0.8-0.037 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 02-0.02 | |

| Feed Concentration (%) | 30-55 | 30-55 | 25-55 | 25-55 | 25-55 | 25-55 | |

| Production Capacity (t/h) | 7-10 | 6-8 | 4-6 | 2-3 | 0.8-1.2 | 0.15-02 | |

| Dimensions | Length(mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 |

| Width(mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 | |

| Height(mm) | 5600 | 5300 | 5230 | 4000 | 2600 | 1500 | |

We are a manufacturer of Jig, integrating manufacturing, production and supply in one. We have a professional after-sales team, there are original parts to provide, maintenance costs are very low.

Sandreck have a dedicated production team. The delivery time of our Jig is generally made within 20 days after the contract is signed.

You can send us a message on WhatsApp(+86 +13666293477) or leave your contact details on our website,later our online customer service will contact you.