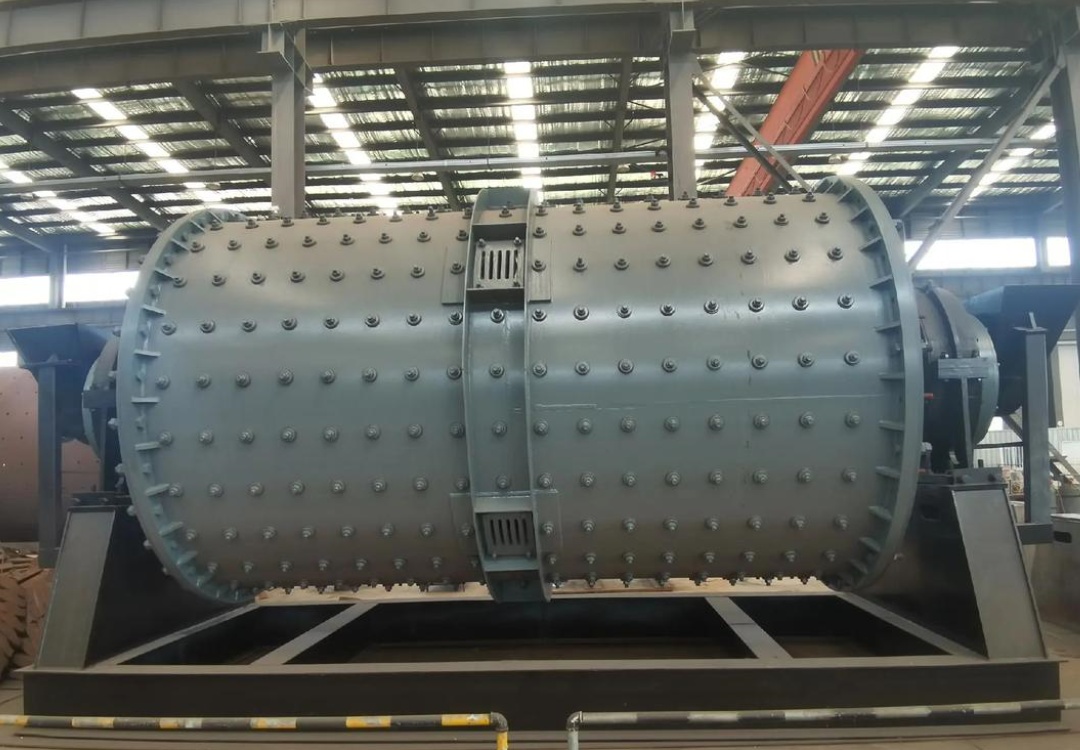

Rod mill

A Rod Mill is a type of milling apparatus which uses steel rods as grinding material. Coarse grinding, liberation, or particle size shaping of ores and other materials is performed in a Rod Mill.

- Production capacity: 9.5-340t/h

- Power range: 132-1000

- Ball loading: 17-94

China's Leading Rod Mill Manufacturer.

The Sandreck Rod Mill, also known as a Rod Sand Mill, is used for artificial sand production, mineral processing in mines, and processing power raw materials in chemical plants. It is a primary grinding machine capable of both wet and dry operation. It can crush high-strength materials with a Mohs hardness of 5.5-12, such as metal ores, quartz, and granite.

The Rod Mill we produce adopts multi-stage grinding technology to effectively control the particle size. It not only meets your strong crushing needs in the coarse crushing stage, but also completes the fine crushing operation, providing you with a reliable industrial grinding solution.

The Rod Mill produced by Sandreck can replace the short-head cone crusher for fine crushing. The configuration is simpler than the cone crusher and the screening machine, and the cost is low. It is often used in soft, small, hard and other material crushing projects.

Advantages of Rod Mill

Sandreck Rod Mill has a PLC one-button control system, which can complete production by pressing a button.

Adopt advanced bearings such as SKF/NSK; the service life is extended by 10-20%.

Built-in fineness control device, easy to adjust the particle size of discharge, which can reach less than 1mm.

Equipped with dust prevention system, meeting national emission standards.

Rod mill is equipped with motors such as Siemens and Huali, with stable operation and high production efficiency.

Rod Mill is very popular in grinding, especially for ores with particle size less than 20-30mm.

Anti-Clogging Design

Our Rod Mills feature a bespoke anti-blocking design for viscous materials, incorporating specialised stirring teeth and a drying system to comprehensively resolve issues with viscous materials within the mill.

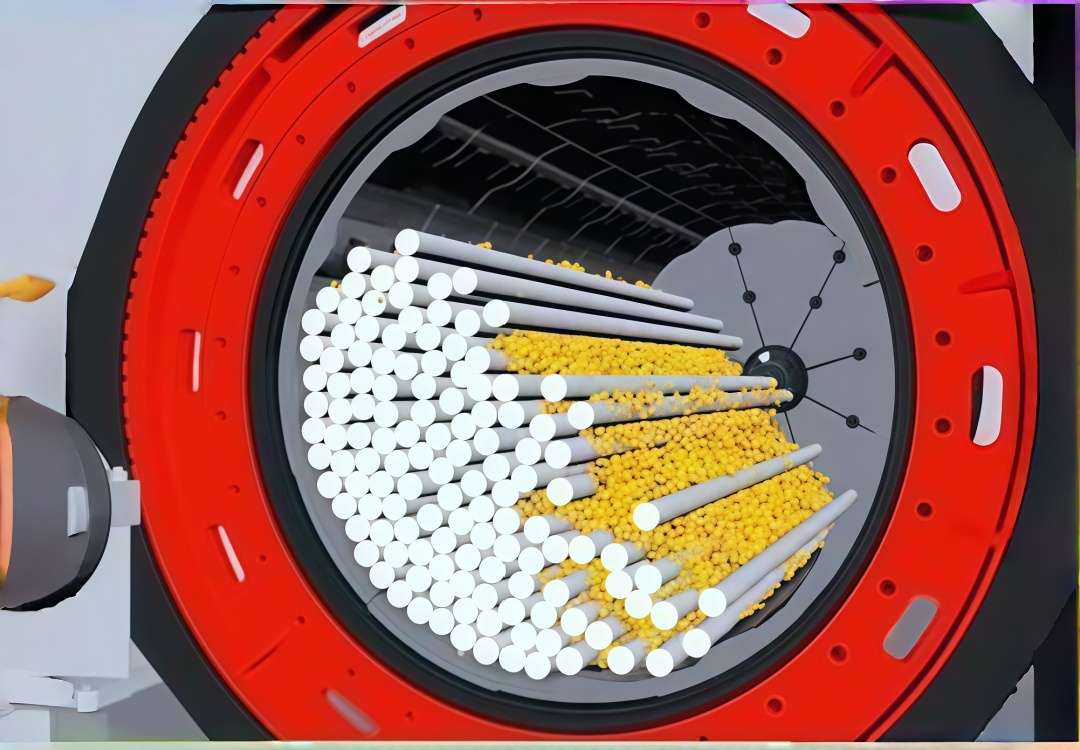

Scientifically formulated wear-resistant steel rods

Wear resistant alloy steel rods used in Rod Mills can extend the life of consumables by 2-3 times thus saving tens of thousand of dollars in consumable costs yearly.

Scientific Ratio Of Steel Rods

Rod Mill science-based proportion of steel rod size insures a uniform particle size discharge. An optionally available intelligent monitoring system, will adjust parameters with the goal of insuring 100% first-pass qualified product(s)!

Steel rod feeding port design

The Rod Mill Manufactured by Sandreck has an innovative side-opening grinding rod replenishment port design, which supports rapid replacement within 1 hour and greatly reduces downtime.

Sandreck Rod Mill: A Comprehensive Grinding Machine for Different Industries

It is a multi-purpose Rod Mill specifically designed to meet the grinding process demands of multiple industries, providing the ultimate grinding solution for metal ores, non-metallic ores, building materials, and specialty materials.

Metal Ore Processing

Rod Mill is designed for “coarse grinding” (grinding 20-50mm raw ore to 1-3mm) of copper, iron, gold and other ores, meeting the stable production capacity in a large plant of 200-500 tons per hour.

Non-Metallic Ore Processing

For materials such as quartz sand and feldspar, rod mills can grind materials to a precise particle size (e.g., 1-2 mm, ≥90% over-grinding) with low over-grinding rates, allowing for quick material changes without affecting flow. It also reduces your classification costs.

Building Materials and Aggregate

Our Rod Mills provide high-capacity raw material grinding (≥300 tons/hour) for cement plants and integrated “grinding and shaping” systems for sand and gravel plants, producing manufactured sand that meets construction standards.

Special Applications

We offer Rod Nill models with chemically resistant stainless steel liners suitable for corrosive materials, as well as mobile and compact models for quick commissioning on temporary projects.

More About Our Company

- Technical Parameters Diagram

Model | Cylinder Size (mm) | Cylinder Speed (r/min) | Rod Loading (t) | Feed Size (mm) | Discharge Size (mm) | Production Capacity (t/h) | Installed Power (kw/h) | Dimensions (mm) | Weight (kg) | |

| diameter | length | |||||||||

| WP200 | 2400 | 4500 | 21 | 30 | <25 | 0.074-5 | 100-200 | 280-315 | 10500*3250*4120 | 65-70 |

| WP300 | 2700 | 4500 | 17.2-18.5 | 51 | <25 | 0.074-5 | 200-300 | 400-480 | 11500*6100*4950 | 75-90 |

| WP500 | 3200 | 4500 | 15.4-16.6 | 60 | <25 | 0.074-5 | 400-500 | 800 | 12600*6450*5250 | 110-130 |

Testimonials

Considering the material characteristics and output requirements, optimize the equipment model to develop in the direction of energy saving, wear resistance and controllable particle size. But at the same time, after-sales service and technical support are also indispensable.

Before operation, conduct a comprehensive inspection of the equipment and the lubrication of each component to ensure that it can be started after it is normal; when starting, listen to the sound of the equipment running and check whether each component is normal.

It is mainly composed of an electric motor, a main reducer, a transmission part, a barrel part, a main bearing, a slow transmission part, a feeding part, a discharging part, an annular seal, a thin oil lubrication station, a large and small gear spray lubrication and a foundation part.

We have a centralized manufacturing facility in China, all our equipment is factory priced; you can send us a WhatsApp (+8613666293477) message and we will get back to you as soon as possible.