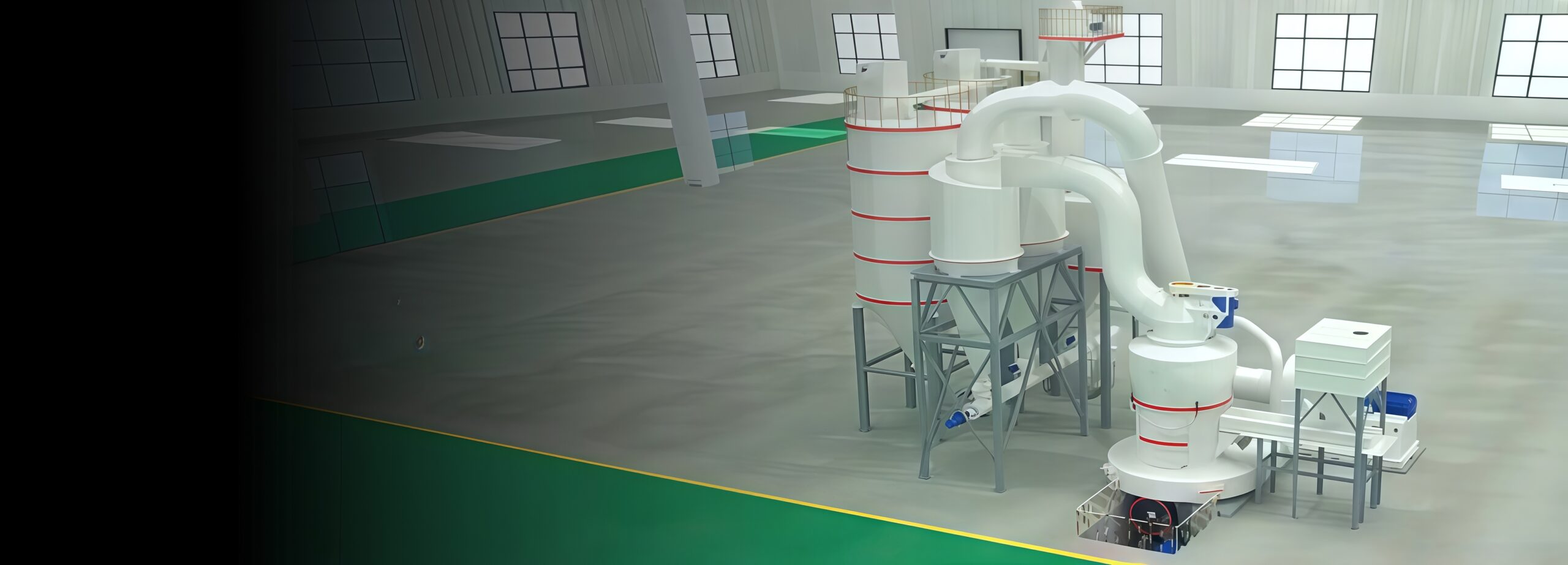

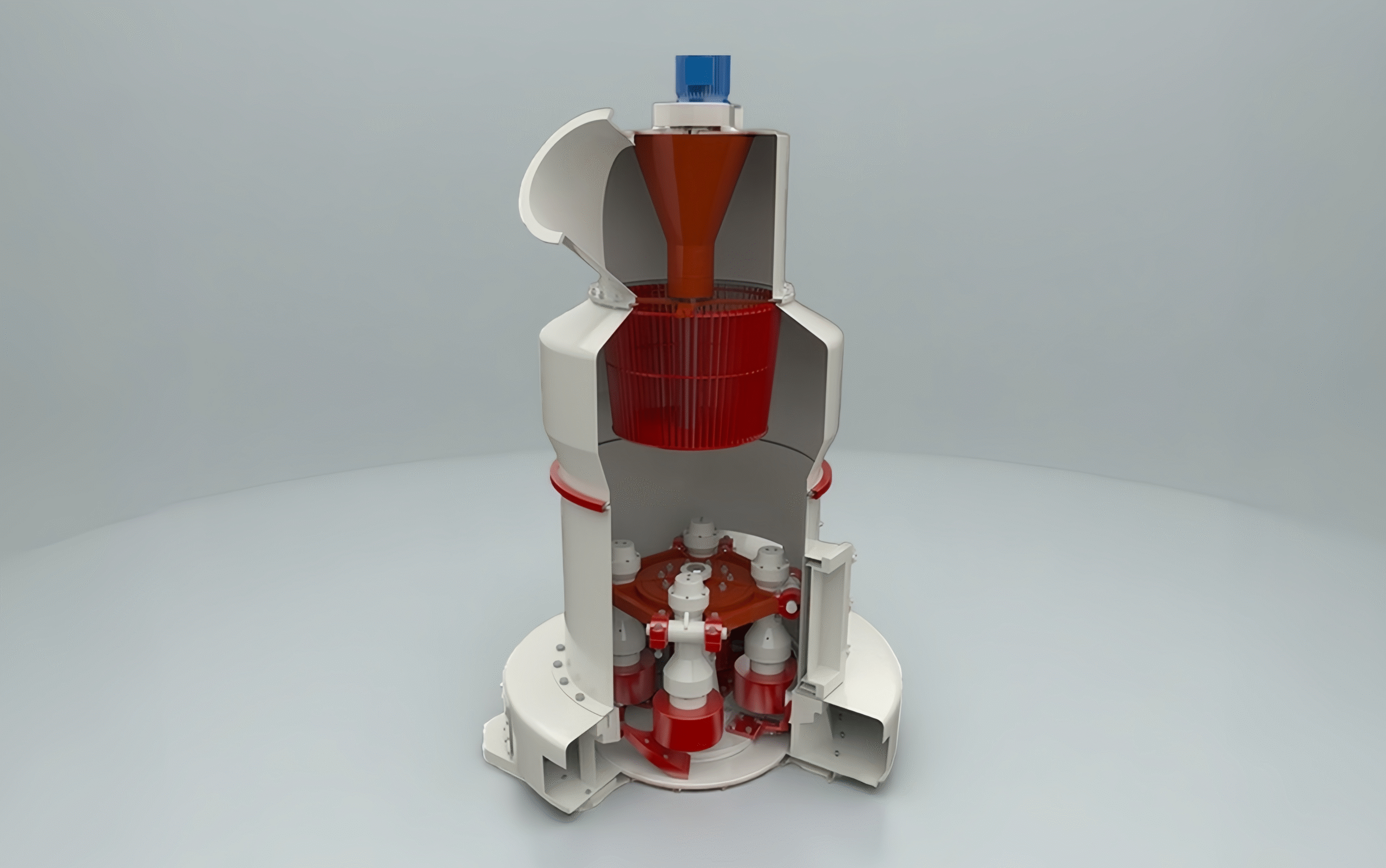

Overview of Sandreck Raymond Mill

Sandreck Raymond Mill is a mechanical pulverizing device convenient for processing raw materials into a fine powder. It widely used for rendring non-flammable,non-explosive brittle mineral products, primarily with Mohs hardness below 7 and moisture content not exceeding 6%.

Feed size: ≤20mm

Fineness size: 80 – 600 mesh(0.175 mm – 0.025 mm)

Output: 3-50 T/H

Your Trusty Raymond Mill Manufacturer in China

Sandreck is a professional Raymond mill manufacturer in China. We own factories in Chengdu and Xinjiang to produce core components by ourselves without intermediary links so as to offer a pure direct supply and a clear price.

Fully enclosed dilute oil bath lubrication system: Detailed oil circuit control in order to achieve oil replenishment of the core components automatically and continuously without hand operation. This system could greatly reduce maintenance times and costs, while to help extend the lifespan of the Raymond Mill parts’ to ensure that continuous and effective production.

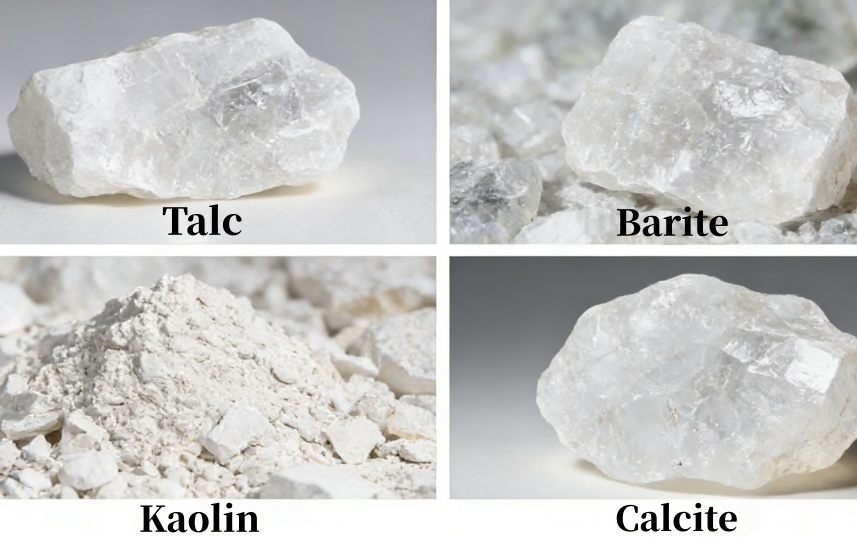

The suitability of processing materials of our Raymond Roller Mills, both in terms of types and fineness, is extremely convenient, conventional non-metallic ore such as limestone, calcite, barite. And other materials can be easily processed, even we are capable of talc ultra-fine grinding and quartz medium to high hardness crushing.

Our Raymond Mill machines work completely in a closed loop air circulation system in favour of preventing the dispersed dust while still meeting the environmental requirements. Simultaneously, it prevents oil contamination and external dust from entering the core area, ensuring long-term stable operation of the equipment.

Types of Raymond Mill

We offer three types of Raymond Mills to comprehensively meet different operational needs.

Raymond Mill

Raymond MillThe finished size range of the Sandreck’s Raymond Mill output is 30 mesh to 325 mesh.

SGM Raymond Mill

SGM Raymond MillThe fineness of the processed product can be adjusted within the range of 80-425 mesh.

OBM Trapezium Grinding Mill

OBM Trapezium Grinding MillThe finished size range of the OBM Trapezium Grinding Mill output is 80 mesh to 600 mesh.

High Wear Resistant Long Life Grinding Roller

The Raymond Mill primarily crushes materials through the action of grinding rollers and grinding rings. As the key consumable parts of Raymond mill, the grinding roller and grinding ring affect the working efficiency of your mill. The Raymond Mill manufactured by Sandreck features large-diameter bimetallic composite grinding rollers(manganese steel + high-melting alloy). This design significantly increases the contact area and pressure between the rollers and the material, resulting in notable improvements in both production capacity and overall grinding efficiency.

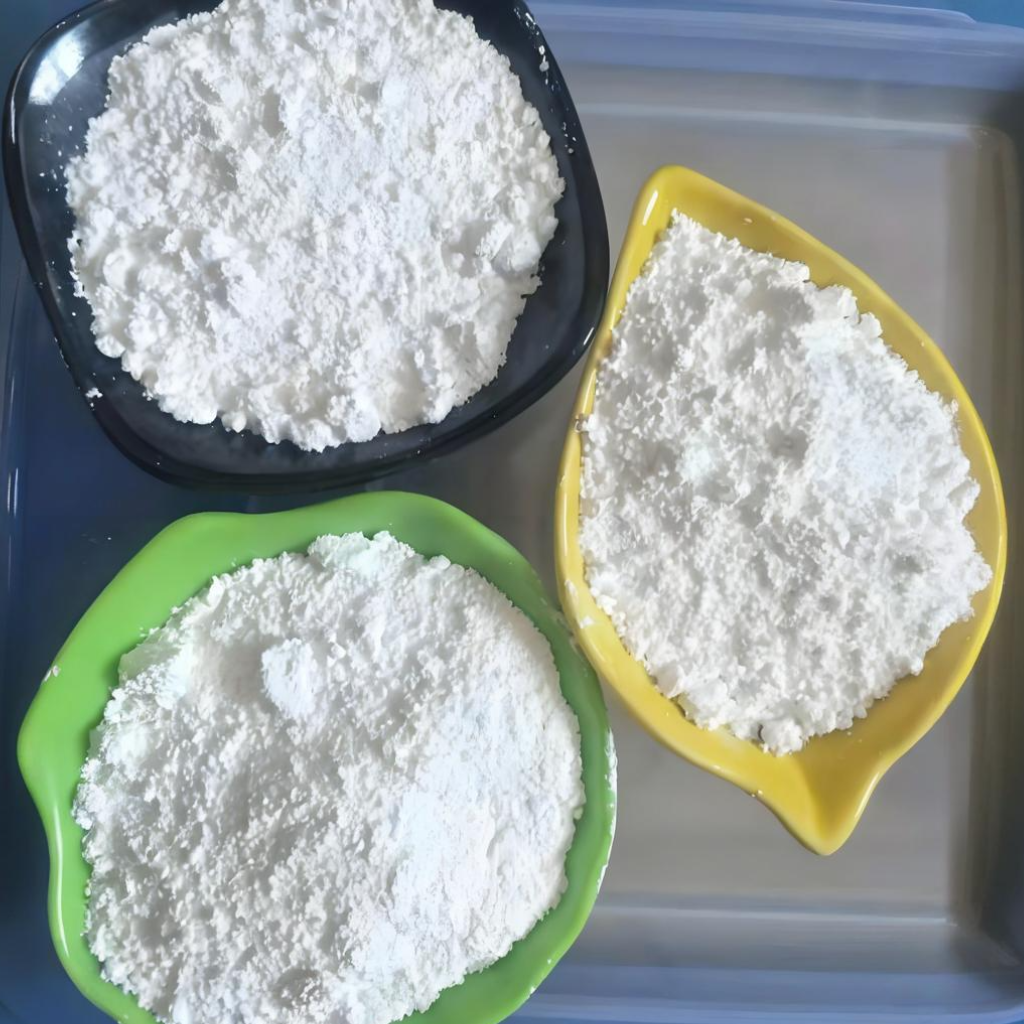

Uniform and Controllable Particle Size of Finished Products

Raymond Mill machines based on Mature Wind Classification and Independent Grinding System, enables precise control of finished product particle size. The resulting powder exhibits a uniform fineness with a 99% qualified screening rate, a performance level that is difficult to match by other grinding mill.

How to select the right Raymond Mill

The first thing to consider is to define some important specifications of the material: if the Mohs hardness is lower than 7; moisture content lower than 6%; 30 mm is the maximum feed particle size, etc.; and the desired fineness. These specifications would directly influence if the Raymond Mill machine would be the right model and configuration for your production needs.

Next, you need to specify the Raymond Roller Mill based on output/production capacity and process requirements. Set the desired hourly output, the frequency of fine adjustment, and confirm if an integrated process (crushing-grinding-classifying-collecting) is necessary, to ensure that the equipment selection is facilitated “in accordance with production rhythm and process flexibility” etc.

Then, you evaluate production efficiency based on your Raymond Mill’s performance comparative results: what is the power consumption per ton of powder? How is the wear-resistant parts and components material and life? Is the classification performance accurate? And the level of automation control? you want to ensure the Raymond Roller Mill remains stable, power saving, and easy to operate in long-term running.

Lastly you optimize the overall configuration based on your operation conditions. The configuration must match the installation circumstances of the installation, emission standard of the environment, load requirements of power supply.Your Raymond Mill machine can adapt to the actual production environment and meet the requirements of sustainable operation.

Wide Range of Applications

Sandreck Raymond Mill serve as a crucial force for non-metallic minerals. Our equipment is widely applied in the following key sectors:

Our Raymond Mill machine is suitable for grinding raw materials such as cement clinker, limestone, gypsum and slag.

Sandreck’s Raymond Mill specializes in processing minerals including calcite, barite, talc, and kaolin.

The Raymond Grinding Mill can be used for pulverizing coal powder, petroleum coke and other raw materials and fine processing of powder pesticide.

Sandreck’s Raymond Mill is designed for fine grinding of raw materials such as feldspar and quartz, reliably producing high-quality powders.

The Raymond Roller Mill can be used for the precision processing of mica, aluminum hydroxide and other flame retardant fillers and functional pigments.

Our Raymond Mills are capable of drying and grinding solid waste such as steel slag and fly ash, supporting green production.

Testimonials

A: Suitable for grinding non-explosive and non flammable minerals with Moh’s hardness below 7 and moisture content less than 6%, such as limestone, calcite, follow me, talc etc.

A: Yes. Raymond Mill classifier speed can adjust the fineness of finished product, generally 80~600mesh, some improvement type even can reach to 800 mesh.

A: Model specification (capacity), material configuration (wear-resistant parts grade), degree of automation, environmental protection accessories (dust removal system), whether installation service included? Follow these factors, price range is large.

A: Generally included installation guidance, commissioning training and a whole machine one year warranty (except wear parts). Sandreck would also offer long-term technical support, spare parts supply, process optimization service.