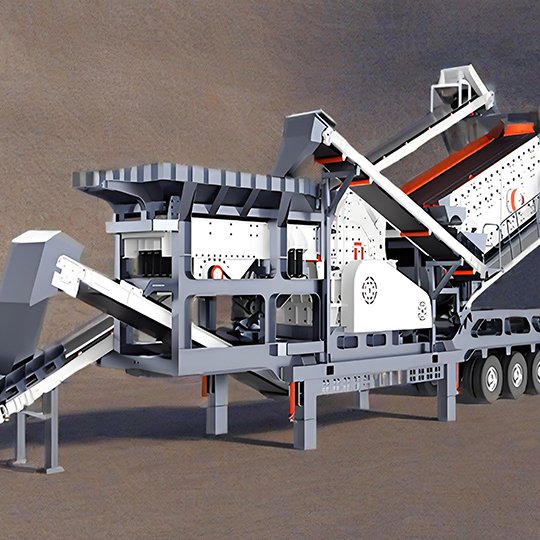

Portable Crushing Plant

Sandreck Portable Crushing Plant is a novel rock crushing equipment which can be driven by electric motor or diesel engine.

- Feed Size:≤800 mm

- Motor power: 100-1000 kw

- Processing capacity:20-500 t/h

What Is Portable Crushing Plant?

The Portable Crushing Plant produced by Sandreck is a Mobile Stone Crushing Equipment, which is a mechanical equipment that crushes large pieces of materials in multiple stages and screens them according to certain discharge specifications. The Portable Mobile Crushing Plant is equipped with tires for easier use. It can be operated independently or as part of a large crusher group. It has various functions, including coarse crushing, medium crushing and fine crushing.

Sandreck Portable Crushing Plant are widely used in on-site operations such as mines, coal mines, garbage and construction waste recycling, urban infrastructure, roads or construction sites.

Product By Features

A Portable Crushing Plant (also called Mobile Crusher) is a modular wheeled crushing and screening equipment that combines crushing and screening functions.

Portable Crushing Plant Advantages

Portable Crushing Plant can be operated alone or flexibly configured with other fixed or mobile equipment.

It uses diesel/electric dual-mode drive, suitable for multi-mine rotation and urban waste recycling projects.

Customized solution design based on material characteristics and working conditions.

No infrastructure required, easy transfer, ready for production upon arrival.

Portable Mobile Crushing Plant has the ability of quick installation, easy operation and low maintenance cost.

The use of tires makes it more convenient to move, especially suitable for the sites needs frequent movement.

Modular Portable Crushing Plants

Our Portable Crushing Plants have a modular design, and each module works separately, fully meeting the requirements of small projects and 24 hours non-stop crushing.

These modules can be assembled quickly into large production lines, and put into operation in less than 24 hours, easily satisfying demand for large-scale production.

Portable Crushing Plant- Dual-Effect Independent Control System

1. Independent oil station

Continuous and stable oil supply and lubrication eliminate risks of malfunctioning due to lack of oil or oil pressure.

The impact crusher model features a hydraulic cover opening system which makes parts replacement rapid and easy.

2. PLC control system

One touch start and stop allows even inexperienced operators to operate the machine independently.

Real-time monitoring of operational statuses and fault self-diagnosing at 92% accuracy.

Sandreck Portable Crushing Plant helps you create value

For sand and gravel aggregate producers, our portable mobile crushing plants allow companies to crush locally at source (river sand, mountain rock), avoiding the cost of transportation.

For mining operations, they gain freedom from fixed sites and are able to move quickly between diverse mining locations saving on fixed infrastructure costs; they can crush both hard ore and soft ore efficiently.

For construction waste recycling companies, they can directly move to demolition sites and crush waste concrete and bricks into recycled aggregates.

Flexible switching of crushing main machine

Sandreck Mobile Crusher can meet your needs of coarse crushing (120-300mm), medium crushing (20-120mm), and fine crushing (≤20mm) by simply replacing the main unit.

Jaw Crushers are typically employed in the primary stage of crushing while processing large ore.

Cone Crushers are often used in the secondary stage of crushing to make smaller the crushing product created during the primary stage.

Impact Crushers are also used in secondary or tertiary crushing to process relatively brittle materials.

VSI Impact Crushers are primarily used in the tertiary crushing stage to produce manufactured sand.

Portable Crushing Plant Cases

Sandreck is a well-known Chinese integrated supplier of crushed stone equipment and solutions, and has provided services for over a thousand sand and gravel processing plants.

Testimonials

Daily maintenance includes regular lubrication of bearings and inspection of wear of wearing parts (such as hammers and liners). It is recommended to perform a basic inspection every 8-12 hours of work.

Most models use energy-saving motors or diesel engines, which consume less energy than traditional fixed crushing equipment, which is suitable for road transportation, and the transfer time is usually less than 1 hour.

Sandreck’s after-sales service includes free installation guidance, 1-2 year warranty, remote technical support and spare parts supply, and customized operation and maintenance training.

You can consult the customer service online through the website or WhatsApp+13666293477, we will contact you within 24 hours.

Related Products

Crawler Crushing Plant is a highly efficient mobile crushing and screening equipment

Vertical Compound Crusher is one of the commonly used equipment in sand making

Tire mobile crushing plant is a modular crushing equipment driven by tire chassis

Intelligent Magnetic Separation technology allows mineral purification in one step