OBM Trapezium Grinding Mill

The OBM Trapezoidal Grinding Mill is an upgraded version of the Raymond Mill, featuring bevel gear transmission, fully thin oil lubrication technology, intelligent PLC central control, and high-efficiency pulse dust removal.

- Feed Size: ≤40MM

- Hourly Output: 3-25t/h

- Fineness: 80-400 mesh

Your Expert OBM Trapezium Grinding Mill Supplier in China

Sandreck is a professional OBM Trapezoidal Grinding Mill supplier in China. We have an independent production base and more than 20 years of manufacturing experience.

We recognize the requirements of the powder usage in different industries. Sandruck’s OBM Trapezium Grinding Mill has been developed with, high efficiency powder selection and classification systems offering controllable fineness of 80-400 mesh to meet these needs.

The OBM Trapezium Grinding Mill is able to process various types of material with a Mohs hardness upto 9.2, including limestone, granite, barite etc. Regardless of your specific area of industry, Sandruck offers a professional grinding solutions and looks forward to being your partner and trusted long-term helper.

Whatever your needs for grinding, Sandruck enjoys providing professional solutions for you and looks forward becoming your trusted, long-term partner.

OBM Trapezium Grinding Mill Advantages

The structure is more compact and occupies less space to reduce project investment.

Equipped with a professional dust collector and overlapping multi-stage seals with good sealing performance.

Grinding roller and grinding ring are made of wear-resistant alloy, which doubles the service life.

Compared with the traditional air duct, ours has a smooth inlet, low resistance, and easy material dispersion.

Equipped with PLC fully automatic intelligent control system, operators can remotely control.

The dust removal effect of the OBM trapezoidal mill fully meets the national dust emission standards.

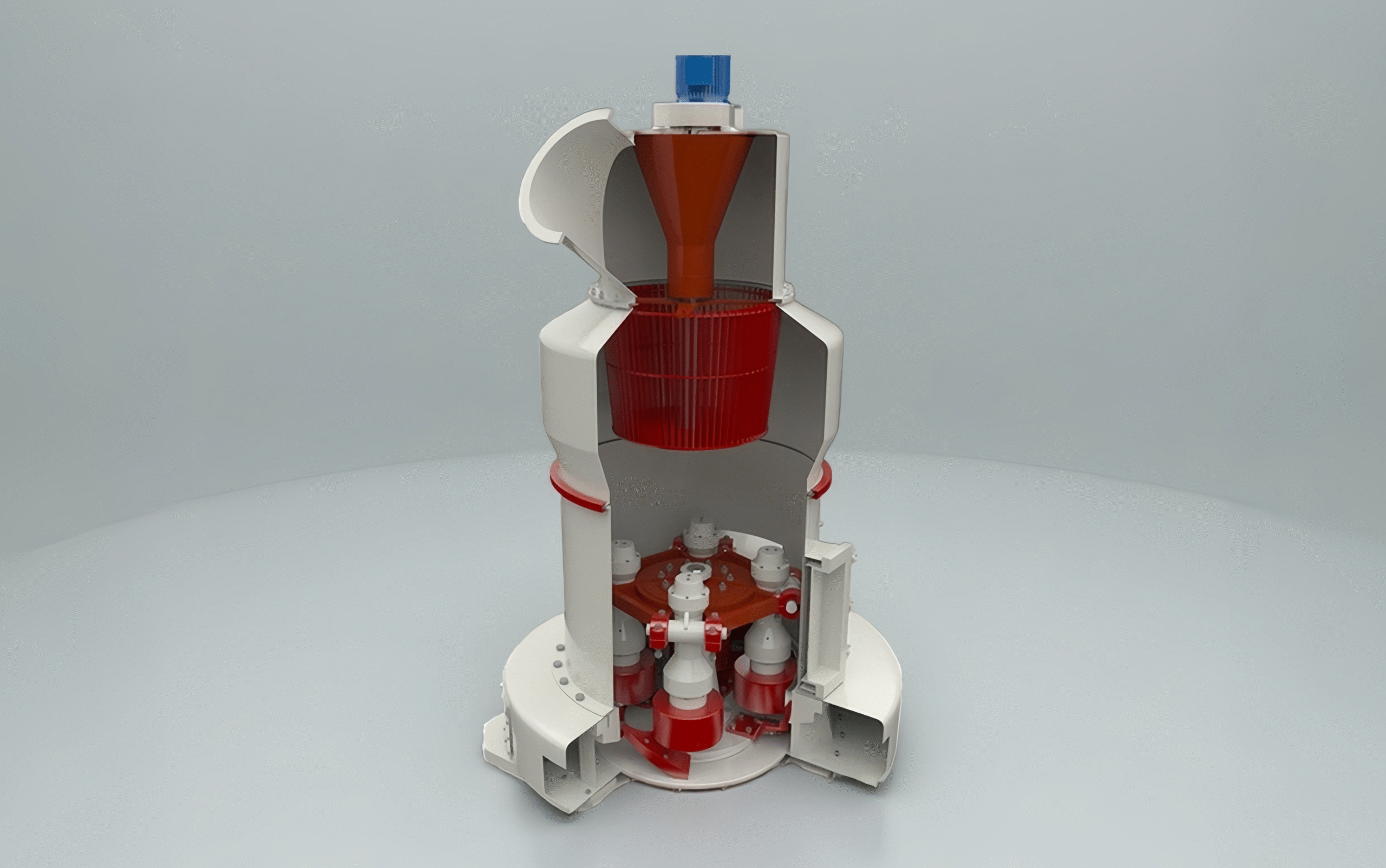

Unique Vertical Swing Grinding Roller Device

As a grinding mill factory, the OBM Trapezium Grinding Mill produced by Sandreck is a vertical swing device that is used horizontally. The centrifugal force of the vertical swing device increases by nearly 35%, which intensifies the crushing energy of the powder, thereby increasing the output by 35%.

The vertical swing device makes the grinding roller and the grinding ring contact in parallel, which is more conducive to powder crushing and uniform wear of the grinding area. The wear of the grinding roller and the grinding ring also becomes uniform, and the service life of the Raymond mill is extended by 30%.

OBM Trapezium Grinding Mill with Adjustable Fineness

If you need finished products of different coarseness and fineness, our OBM Trapezium Grinding Mill can achieve this by adjusting the type, size and filling amount of the grinding media, or controlling the grinding time. Whether it is coarse grinding or fine grinding, it can handle it, completely according to your needs.

How Does OBM Trapezium Grinding Work?

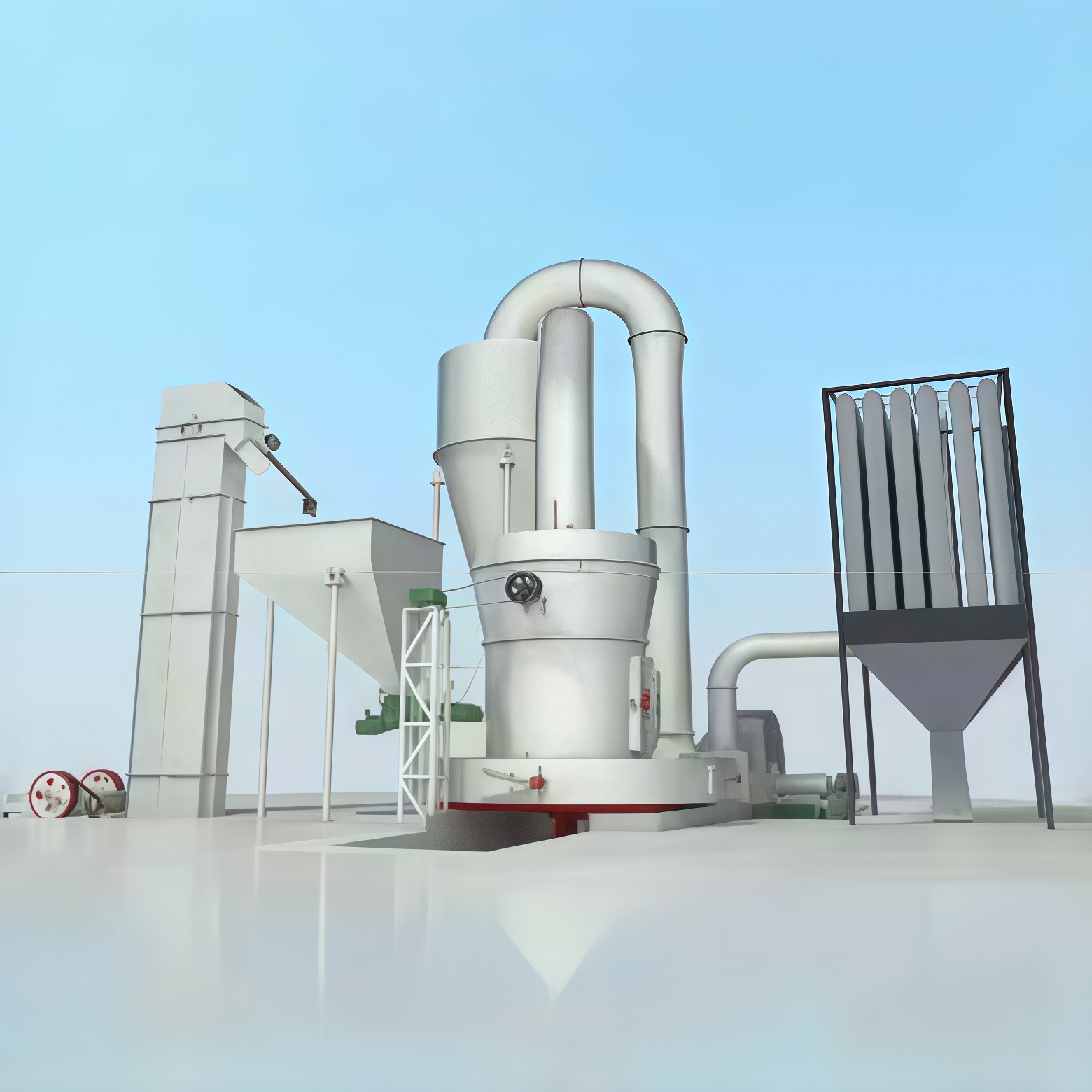

Sandreck’s OBM Trapezoidal Grinding Mill utilizes a continuous, air-circulating, closed-circuit process, consisting of four main steps or stages

1. Feeding and Grinding

The OBM Trapezoidal Grinding Mill feeds the material into its grinding chamber in a uniform manner via a feeding device. The grinding rollers and grinding rings crush the material using centrifugal force combined with scrapers.

2. Classification and Return

The airflow transfers the material to the classifier at the top of the OBM Trapezoidal Grinding Mill. Materials meeting the criteria for fine powder move into a collection system, while materials that do not meet the criteria flow back into the main mill for re-grinding.

3. Product Collection and Airflow Circulation

The qualified material exits the main mill into the cyclone powder collector through a pipeline for solid-gas separation. The material which has been separated from the gases is considered the finished product.

The clean air that is separated moves back into the main mill through a return pipe that is driven by a fan, enabling a closed inorder efficient negative pressure circulation airflow system.

4. Environmental Dust Removal

Residual gas and fine powder move to a dust collector in which dust is collected and purified gas is discharged, meeting environmental demand.

OBM Trapezium Grinding-Your Exclusive Customization

Are you new to the OBM Trapezium Grinding Mill? Don’t fret. Sandruck customizes your equipment to better serve your needs

We will customize the power and classifier selection of your OBM Trapezium Grinding Mill based on your material hardness, moisture content, and the output that you require to ensure optimal processing capabilities and energu efficiency.

We can customize the classifying system of the OBM Trapezium Grinding Mill to your finished product fineness specifications. We will provide full 80-400 mesh control so that your powder meets your quality standards.

We will consider the plant conditions of your site, in which we will provide a complete feeding, discharging, and dust control process integrated into the new Grinding Mill mill system.

We will accommodate your schedule of production for installation, commissioning, and training for your Grinding Mill. We will create a profile for service support and adequately respond to your after-sale needs to ensure sustained production.

Trapezium Grinding Mill Cases

Sandreck is a well-known Chinese integrated supplier of crushed stone equipment and solutions, and has provided services for over a thousand sand and gravel processing plants.

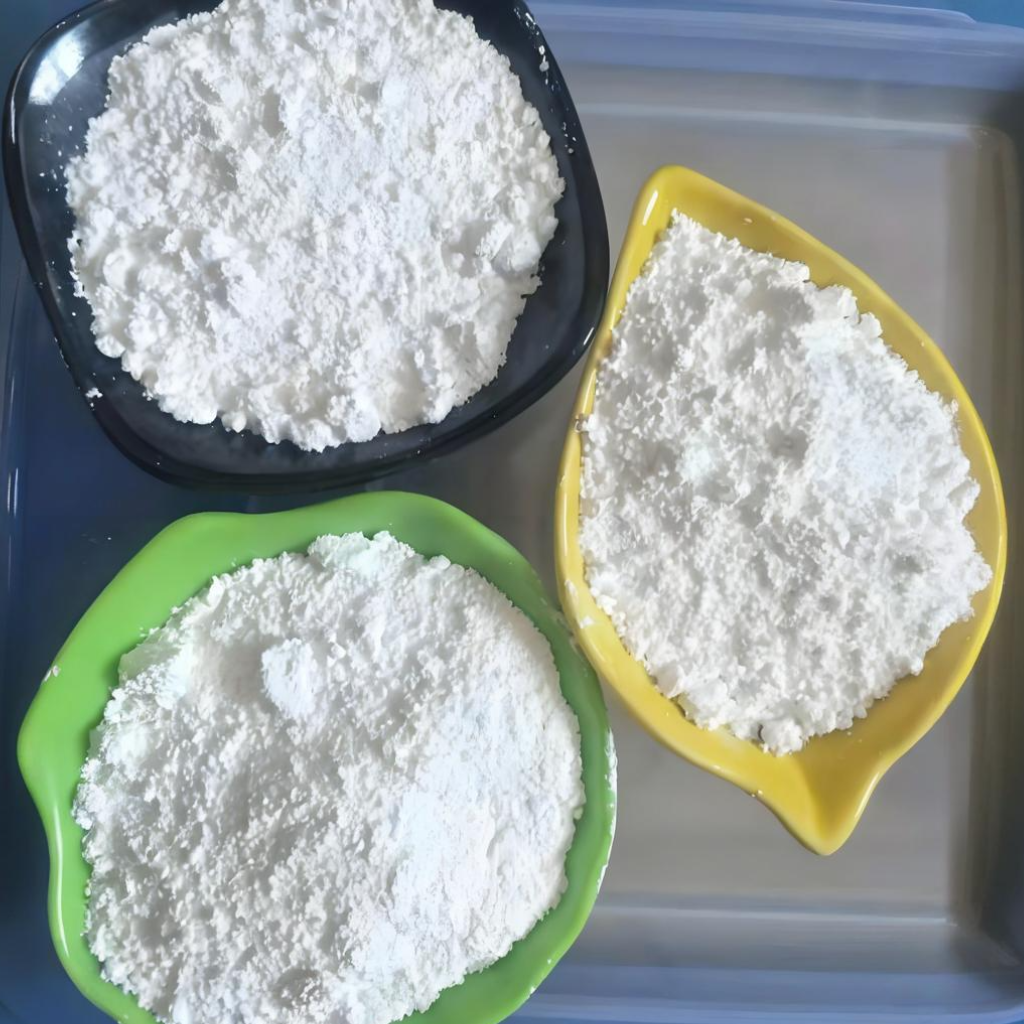

Processing material: Calcium Carbonate

Capacity: 50-100 t/h

Finished product particle size: 80-400 mesh

Processing material: marble

Capacity: 30 t/h

Finished product particle size: 80-400 mesh

More About Our Company

- Technical Parameters

- Technical Parameters

| Specifications | OBM115G | OBM145G | OBM158G | OBM178G | OBM198G | OBM218G | |

| Number of Grinding Rollers( PCS) | 4 | 4 | 4 | 4 | 5 | 5 | |

| Host Speed (r/min) | 110- 125 | 86-110 | 80-95 | 65-90 | 60-75 | 55-70 | |

| Maximum Feed Size (mm) | 30 | 35 | 38 | 40 | 40 | 50 | |

| Finished Product Size | mm | 1.6 -0.045 finest 0 .038 | |||||

| Mesh | 10- 325, finest 400 | ||||||

| Yield (t/h) | 3- 12 | 6 -23 | 8-30 | 10-38 | 15-46 | 18- 55 | |

| Dimensions(mm) | 8425*7933*8642 | 8971*9630*11185 | 10200*9100*10100 | 10268*9595*10351 | 12150*12500*11000 | 14960*12440*11560 | |

| Name | Project | Specifications, Technical Parameters | ||||||

| OBM115G | OBM145G | OBM158G | OBM178G | OBM198G | OBM218G | |||

| Main Engine Motor | power (kW) | 55-75 | 110- 132 | 132- 160 | 185-200 | 220-250 | 280- 315 | |

| Powder Classifier Speed Regulating Motor |

power (kW) |

7.5 – 11 |

18.5 – 30 | 22- 30 | 30- 37 | 37- 55 | 55-75 | |

| Centrifugal Fan Motor | power (kW) | 55-75 | 110- 132 | 132- 160 | 185-220 | 220-250 | 280- 315 | |

|

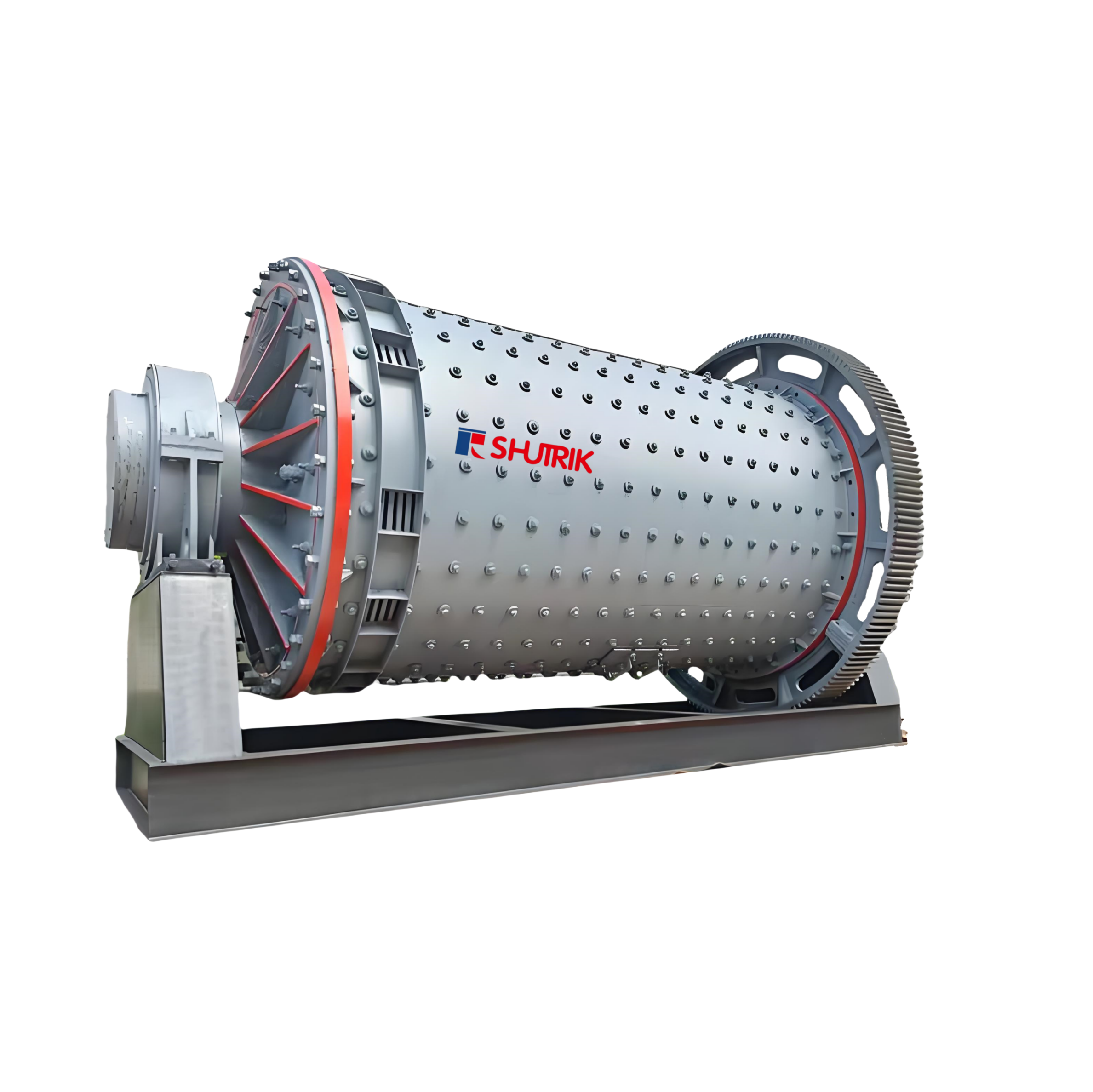

Auxiliary Machine Part (reference) |

Crusher |

model

| PE250*400 | PE250*750 | PE250*750 | PE250*1000 | PE250*1200 | PC1010 |

| motor power(kW) | 15 | 22 | 22 | 30 | 37 | 110 | ||

|

Recommend | model | TH200*8.13m | TH300*9.55m | TH300*9.55m | TH300*10.55m | TH300*13.05m | TB315*12.43m | |

| motor power(kW) | 3 | 4 | 4 | 4 | 5.5 | 11 | ||

| Feeder | model

| GZ2F | GZ3F | GZ3F | GZ4F | GZ5F | GZ5F | |

| power (kW) | 0.15 | 0.2 | 0.2 | 0.45 | 0.65 | 0.65 | ||

| Buffer Bin | capacity ( m³) |

1.5 | 2.5 | 3.3 | 4.5 | 22.4 | 22.4 | |

According to factors such as material characteristics, output requirements and energy consumption, comprehensively consider equipment quality, degree of automation and environmental protection performance to ensure high efficiency, durability and compliance with production requirements.

When using, it should be noted that it is forbidden to process flammable and explosive materials with high water content, and start, run and stop in strict accordance with the operating procedures to ensure safety.

The main components include supporting equipment such as the main machine, powder selector, fan, dust collector, as well as core components such as grinding rollers, grinding rings, pressure springs, plum blossom racks, and scraper systems.

We are a Chinese grinding mill factory, each unit is at factory price, you can leave a message via WhatsApp (+8613666293477), we will contact you as soon as possible.