MW Ultra-Fine Grinding Mill

MW Ultrafine Grinding Mill, also known as Ring Roller Grinding Mill, is a machine that grinds solid materials into powder.

- Feed Size: ≤20MM

- Capacity: 5-45 T/H

- Particle size: 400-3000 mesh

Your Expert MW Ultra-Fine Grinding Mill Supplier in China

Sandreck high-quality MW Ultrafine Grinding Mill is a leading equipment in the field of fine grinding, specially designed for high fineness grinding needs. Whether it is calcium carbonate, talc, barite or other non-metallic minerals, our MW MW Ultrafine Grinding Mill can achieve precise crushing to meet the high standards of global customers.

It is mainly used for medium and low hardness, non-flammable and explosive brittle materials with Mohs hardness ≤ 6, such as calcite, limestone, dolomite, barite phosphate rock and other materials. The finished product particle size can be adjusted arbitrarily between 80-300 mesh.

MW Ultra-Fine Grinding Mill Advantages

Adopts the ring roller grinding principle, uniform particle size, the fineness can reach 5-45 microns.

The optimized design reduces energy consumption, saves 30% energy compared with traditional one.

The components are made of wear-resistant materials, long service life and reduced maintenance costs.

Equipped with an efficient dust removal system, the dust emission meets international standards.

Automated control system, simple operation and convenient maintenance.

Under the same fineness, it has less investment than the air flow mill, low cost and short recovery period.

MW Ultra-Fine Grinding Mill Application Range

Sandreck is a Grinding Mill Factory in China, our MW Ultrafine Grinding Mill is usually used in many industries such as mining, building materials, chemical industry, metallurgy, thermal power, coal, etc. It can easily adapt to and become your stable partner in the mineral processing production line.

MW Ultra-Fine Grinding Mill Application Range

With the same final particle size and power, you will find that Sandreck MW Ultrafine Grinding Mill produces twice as much product as air and agitation mills, which will undoubtedly greatly improve your production efficiency.

Sandreck’s MW Ultrafine Grinding Machine embodies more than 30 years of production experience and integrates the advantages of domestic and foreign Mill manufacturers. It provides you with a new type of efficient and reliable Ultrafine powder processing equipment to help you easily cope with production challenges.

Company Advantage

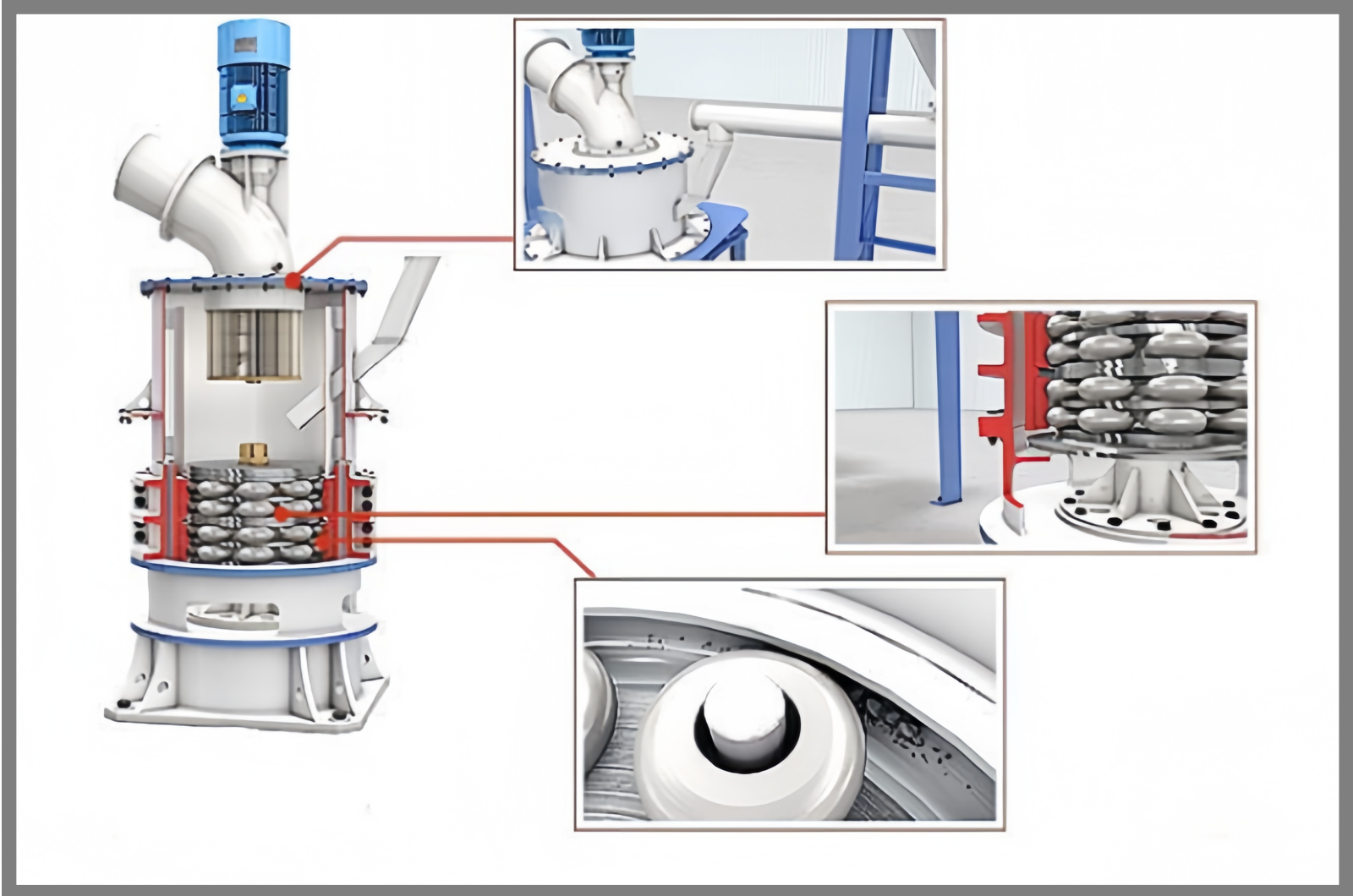

The Ultra-Fine Grinding Mill manufactured by Sandreck is a grinding mill that utilizes the rolling, impacting, and grinding effects of multi-layered ring rollers.

Quantified feeding and initial stage separation

The feedstock is placed into a grinding chamber and dispersed by centrifugal force.

Lake of multi-layered cyclical comminution

The material progressively falls in order from layer to layer (usually four) of grind rings and rollers and is pressed, rolled, and ground continuously while not losing the ability to pulverize.

Air conveyance and separation

The ground material is drawn into the classifier by negative pressure air flow from the induced draft fan. Coarser particles are separated from the air stream and fall back into the grinding chamber to be re-ground.

Product collection

The fine powder is directed out and to a cyclone / bag dust collector and the finished product is discharged through the valve. The remaining purified air is exhausted out through fans and silencers.

MV Ultra-Fine Grinding Mill Parts

Sandreck’s MW Ultrafine Grinding Mill are equipped with tungsten carbide grinding rollers and rings (hardness HRC65+) with precisely matched rings resulting in a wear life of greater than 12,000 hours and a 30% reduction in the frequency of part replacement.

The MW Ultrafine Grinding Mill comes with a variable frequency intelligent classifier so you can adjust the fineness of the ring roller mill with a single touch from 80-400 mesh. The finished product D97 deviation is ≤1% and the pass rate is greater than 99.5% thus eliminating the chance of dismissal due to unstable fineness.

Using a high-efficiency pulse dust collector with a dust collection rate of ≥99.9% during production throughout the entire process Sandreck’s ring roller mills are dust-free and easily comply with the environmental requirements while also recovering fines according to the environmental requirements.

Sandreck’s MW Ultrafine Grinding Mill have a variable frequency motor with a precision reducer allowing flexible speed adjustment according to material hardness, leading to greater than 10% energy savings, reducing overloads and stalling, and operate the entire production line continuously.

More About Our Company

- Technical Parameters

- Technical Parameters

Specifications | MW880 | MW1080 | MW1280 | MW1680 | |

| Average Working Diameter ( mm) | 800 | 1000 | 1250 | 1680 | |

| Maximum Feed Size(mm) | 10 | 10 | 15 | 20 | |

| Host Speed(r/min) | 230-240 | 180-200 | 135- 155 | 120- 130 | |

| Yield (kg/h) | 500 – 5000 | 1000-8500 | 1500- 11200 | 5000- 25000 | |

| Ring Roller and Roller(PCS) | 21 | 28 | 32 | 36 | |

| Number of Rings(PCS) | 3 | 4 | 4 | 4 | |

| Finished Product Size | μm | 45-3 | 45-3 | 45-3 | 45-3 |

| Mesh | 325- 3250 | 325- 3250 | 325- 3250 | 325- 3250 | |

| Dimensions(mm) | 13.9*4*6.2 | 18*4.6*8.6 | 14*9*10.25 | 26. 3*7.5*11 .9 | |

| Total Weight of The whole Equipment(t) | 18 | 36 | 56 | 102 | |

Name | Project | Model/Specification | |||

| MW880 | MW1080 | MW1280 | MW1680 | ||

| Main Engine Motor | power(KW) | 55-75 | 110-132 | 185-200 | 315 |

| Analytical Machine Frequency Modulation Motor | power(KW) | 18.5 | 30-37 | 37-5*4 | 18.5*5 |

| Wind Turbine | power(KW) | 45 | 75 | 45*2-55*2 | 75*2-90*2 |

| Hammer Crusher | model | PC400*600 | PC400*600 | PC600*800 | PC600*800 |

| power(KW) | 18.5 | 18.5 | 45 | 45 | |

| Skirt Belt Feeding Machine | model | QB300*60*1.8 | QB300*60*1.8 | QB400*80*2 | QB400*80*2.8 |

| power(KW) | 1.5 | 1.5 | 1.5 | 1.5 | |

| Hoist | model | TH200*9.79 | TH300*11.05 | TH300*13.55 | TH300*16.31 |

| power(KW) | 3 | 3 | 5.5 | 7.5 | |

| Screw Conveyor | model | LS219*4.5 | LS245*6.2 | LS315*10.34 | LS315*10.34*2 |

| power(KW) | 3 | 4 | 7.5 | 7.5*2 | |

| Discharge Valve | model | ZJD200*2 | ZJD250 | ZJD300 | 300*2 |

| power(KW) | 0.75*2 | 1.1 | 1.5 | 1.5*2 | |

| Pulse Dust Collector Air Compressor | model | LGY-2.8/8 | LGY-5/8 | BK37-8G | BK55-8G |

| power(KW) | 15 | 30 | 37 | 55 | |

Regularly check the wear of grinding rollers, grinding rings, and bearings, lubricate and maintain them in time, avoid overload operation, and ensure uniform feeding of materials.

Grinding rollers and grinding rings are usually replaced every 6-12 months, and bearings and seals are replaced every 1 to 3 years.

You can leave us a message via WhatsApp (+86 13666293477), or click here add your address. our online service will contact your later.