Mobile Impact Crusher

Sandreck mobile impact crusher is mostly used for fine

- Feed Size: ≤800MM

- Moter power: 220-630KW

- Processing capacity: 50-500T/H

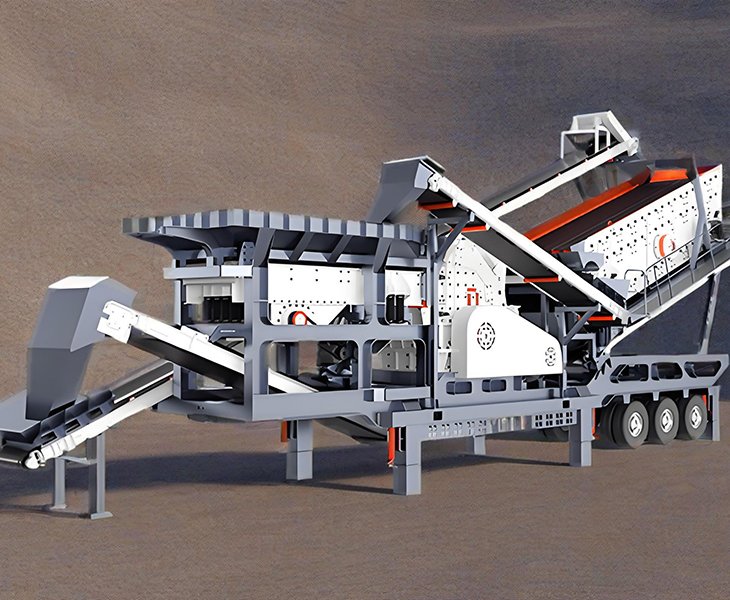

What Is Mobile Impact Crusher?

The Mobile Impact Crusher produced by Sandreck is used for secondary crushing of stone. Whether you are processing sand and gravel aggregates, mining or building demolition, it can easily handle the crushing of medium-hard materials (such as river pebbles, granite, limestone, etc.) you need. The mobile chassis design allows the equipment to be moved anywhere, and the crushing is no longer limited by working conditions.

Sandreck Mobile Impact Crusher is equipped with a screening system, and is often combined with a Jaw Crusher to form a “coarse crushing + fine crushing” production line. It can be flexibly transferred to narrow sites to handle construction waste and high-hardness stones. The finished product has uniform particle shape and the efficiency is increased by 30%!

Mobile Impact Crusher Advantages

Sandreck Mobile Impact Crusher adopts tire chassis, which can quickly transfer sites and reduce material transportation costs.

Sandreck Mobile Impact Crusher integrates multiple equipment and can be put into production in 30 minutes, saving time and effort.

Sandreck provides original parts supply service to ensure that your mobile impact crusher can be operated without worries.

Sandreck Mobile Impact Crusherhas a fully enclosed structure to meet the environmental protection requirements of construction.

Our Mobile Impact Crusher can crush medium-hard materials such as granite, limestone, and concrete, etc., which can meet your various need.

Sandreck Mobile Impact Crusher adopts high-chromium plate hammer, and the life of wear-resistant parts is extended by 40%.

Multi-stage Crushing, Flexible Screening

Sandreck Mobile Impact Crusher is a multi-purpose machine. You only need to control it with one button to achieve efficient and continuous production. Our Mobile Impact Crusher adopts the latest manufacturing technology to directly meet your high-quality sand and gravel aggregate production needs.

More About Our Company

- Technical Parameters

- Case Picture

Device Model | Feeding Equipment | Crushing Equipment | Main Belt Conveyor | Silo Capacity (m³) | Maximum Feed Size (mm) |

| KPFW421 | GZD0936 | PFW421 | B1000x8.3m | 5.3 | 400 |

| KPFW521 | GZD1345 | PFW250 | B1000x9.5m | 8 | 500 |

| KPFW621 | GZD1548 | PFW621 | B1200x9.5m | 11 | 700 |

Sandreck Mobile Impact Crusher uses impact force to break materials. The rotor rotates at high speed, hitting the material and breaking it into smaller pieces.

Sandreck Mobile Impact Crusher requires regular maintenance to check wear parts. You can consult us for any maintenance issues after purchase.

Sandreck Mobile Impact Crusher spare parts cost varies, and using high-quality parts can reduce long-term costs. We have professional maintenance personnel to help you solve it.