Cheap Mobile Crusher Plant Companies

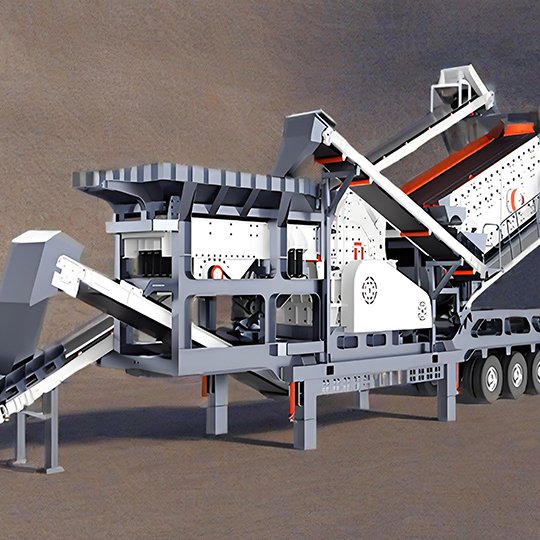

Mobile Crushing Plant is a modular crushing equipment driven by tire chassis.

![]() Unhindered all-terrain travel and easy transition

Unhindered all-terrain travel and easy transition

![]() Process nearby, large stones are crushed into standard sand and gravel on site

Process nearby, large stones are crushed into standard sand and gravel on site

![]() No need to lay foundation/build factory, just connect the power and start working

No need to lay foundation/build factory, just connect the power and start working

Your Expert Mobile Crushing Plant Supplier in China

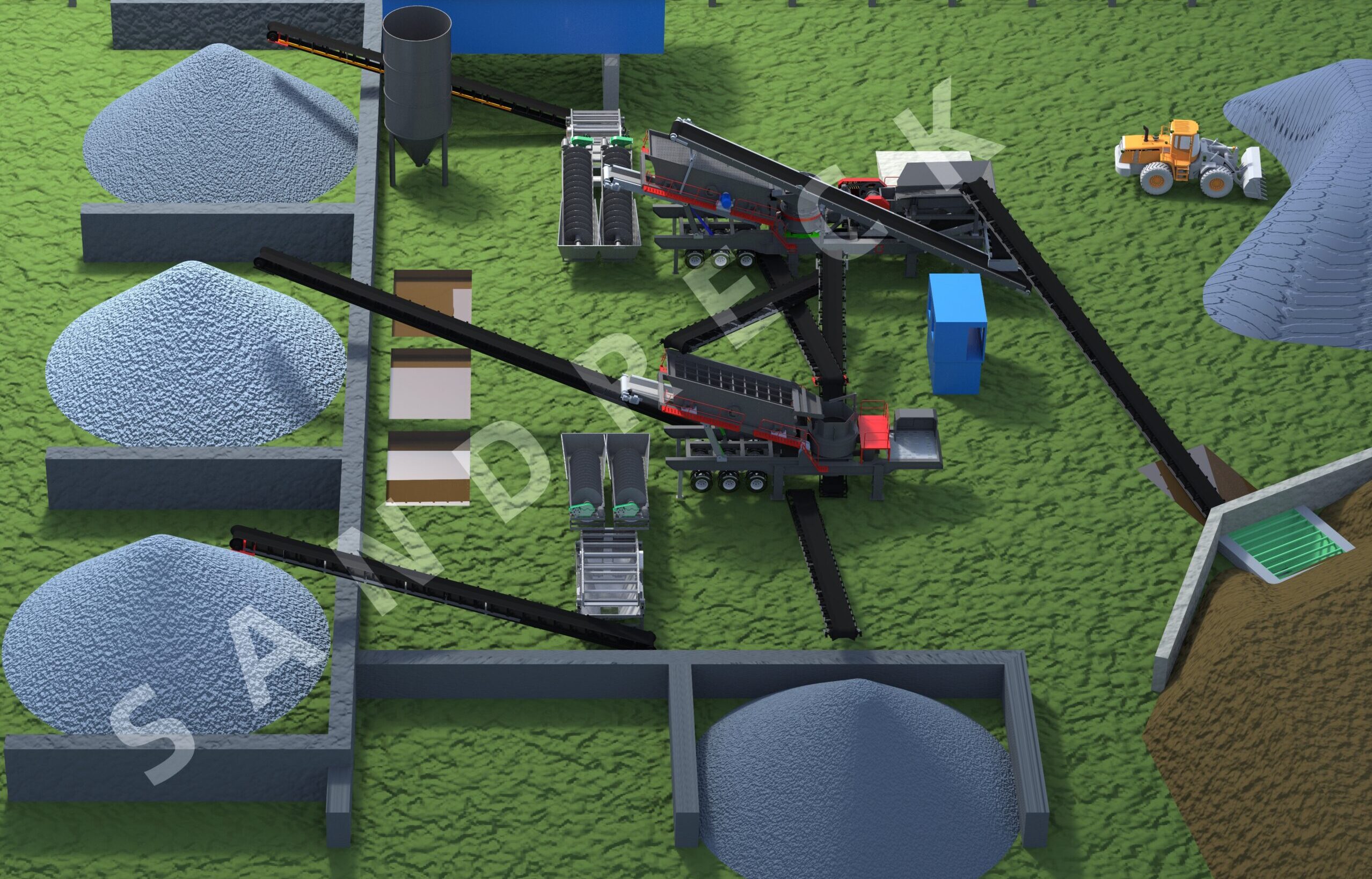

Sandreck Mobile Crushing Plant provides you with modular crushing solutions, integrating the whole process of coarse crushing, medium crushing, fine crushing, shaping, sand making and screening. It is mainly used for material processing that often requires mobile operations in metallurgy, chemical industry, building materials, hydropower, etc., especially for the processing of mobile stones such as highways, railways, and hydropower projects.

Sandreck Mobile Crushing Plant can be operated independently or can be composed of “crushing first and then screening” or “screening first and then crushing” according to your crushing process requirements.

As a major Mobile Crushing Equipment manufacturer in China, the equipment is made of Q355B wear-resistant steel plate, and available customizable wear resistant options such as high-chromium cast iron, high-chromium alloy, and composite ceramics, all made to last for long-term use for materials like granite and construction rubbish.

Product By Feature

Equipped with high-performance Impact Crusher and Screening Equipment.

Mobile Cone Crusher’s important equipment for fine crushing in stone.

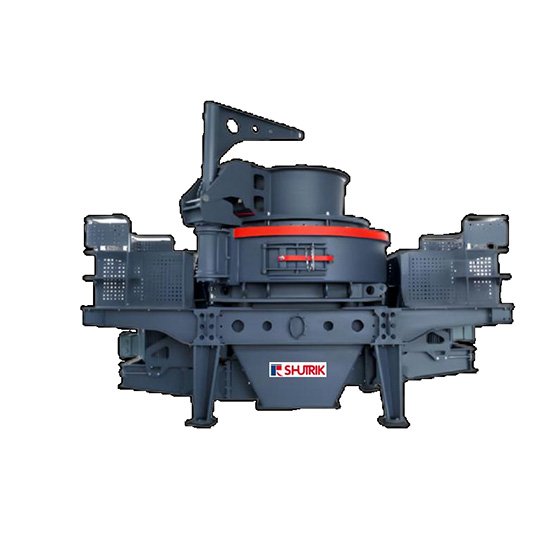

Mobile Sand Making Machine is a portable VSI Crushing and Screening Equipment.

Suitable for crushing of various hardness and is flexible to move.

Mobile Stone Crusher is suitable for crushing aggregates of various hardness.

Mobile Rock Crusher is used to crush various types of stones and is flexible to move around.

Crushing and Screening of large reinforced concrete in the concrete recycling industry.

Mobile Crushing Plant Advantages

Our machine adopts integrated unit equipment installation form, with reasonable and compact layout.

Sandreck Mobile Crushing Plant can adopt a dual-machine configuration, and the main machine can be changed.

Our machine uses a modular concept to meet crushing needs with only a replacement of the main engine.

Sandreck Mobile Crushing Plant adopts centralized lubrication to save labor costs.

Sandreck has more than 100 processing equipment, which is more accurate.

Sandreck is a company integrating sales and production, providing you with original parts service.

Customized Services

When faced with the numerous and diverse models, do you feel at a loss as to how to proceed?

Different material characteristics, production capacity demands, site conditions and environmental protection standards make the selection process extremely challenging!

But don’t worry – we have been deeply involved in the field of crushing and screening for many years, and we are well aware of the uniqueness of each project.

Your problem is precisely the starting point of our professional value!

New To Crushing? Sandreck Is Here To Help!

At Sandreck, we focus not only on equipment performance but also on saving your team money and ultimately increasing your profitability.

We understand that high operating costs and inefficient traditional processes are barriers to profitability. Our mobile crushing solutions will help you:

1.Significantly reduce operating costs

2.Maximize operational efficiency

3.And achieve a rapid return on investment.

These professional crushing equipment will become a valuable asset on your construction site, helping you stand out from the competition!

Why Choose Sandreck Mobile Crushing Plant?

Mining: our mobile crusher can drive into the mine pit, then the crushed stone can be loaded directly into trucks by its belt making your transportation cost to near zero especially where your mine is an open-cut mine.

Disposal of construction waste: our mobile crusher can crush concrete blocks on-site, and after being recycled, can be used as the aggregates used in making bricks for paving roads thereby really changing your waste into products.

For infrastructure or emergency repairs: Our mobile crushing equipment can arrive on-site and crush and recycle at any location, saving significant time and thousands of dollars in lost work.

And ready-mix concrete plant: with our mobile crusher, can make the 0-5mm adjustable sand and gravel aggregate for the different grades of concrete allowing you to be flexible and efficient in your production methods.

Modular Mobile Crushing Plant

The Mobile Crusher can change freely between main jaw crushers, cone crushers, impact crushers, and VSI crushers, addressing your mixed production needs.

The Jaw Crusher is a coarse crushing equipment crushed by a periodically jaws of fixed and movable jaws plate, which can be broken through a lot of hard materials.

Cone Crushers perform medium and fine crushing. Cone Crushers generally crush at the order of 25 to 60 mms; and fine crush (which is generally at the order of 3 to 15 mms).

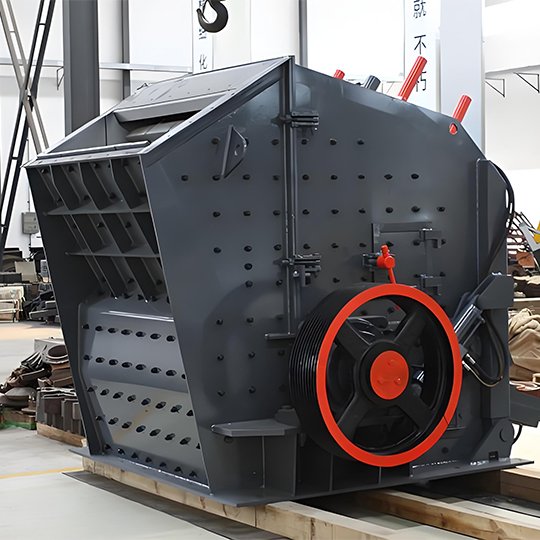

Impact Crushers are a type of medium and fine crushing machine that use impact energy (typically on breakhard and brittle materials, such as limestone, concrete chips, etc…).

VSI Crusher is a fine crushing machine that ultimately crushes through impact and collision making it more suitable to make better quality mechanically manufactured sand.

Mobile Crushing Plant Cases

Sandreck has offered high-quality, efficient crushing solutions to 1,000 large aggregate producers globally – you can experience the best production benefits under various application scenarios.

Processing material: Cobblestone

Capacity: 150-200 t/h

Finished size: 12 stone, 13 stone, mechanism sand

Processing material: quartz

Capacity: 200-400 t/h

Finished size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

Processing material: phosphate ore

Capacity: 100 t/h

Finished product size: 12 stone, 13 stone, mechanism sand

Processing material: Sandstone

Capacity: 50-150t/h

Finished product size: 0-50mm

Testimonials

Sandreck Mobile Crushing Plant is an integration of Crusher, Screener and Conveyor, which breaks down materials into smaller sizes so that the crushed materials can be reused or easily transported.

Sandreck Mobile Crushing Plant checks the lubrication points daily, the hydraulic system weekly, and performs comprehensive maintenance for 500 hours.

The basic model of Sandreck Mobile Crushing Plant is ¥300,000-¥1 million, and the high-end configuration is more than ¥1.5 million.

Sanreck has a professional Mobile Crushing Plant production team, we will complete the delivery within 20 working days after signing the contract.

Related Product

Linear feeding equipment that continuously feeds materials into the crusher.

Used for grading and screening in the fields of minerals, quarries, building materials, etc.

Transfers materials between processes, connecting crushing, screening, washing, etc.