Magnetic Drum

- Waste rock recycling

- Magnetite Pre-Selection

- Crushing system impurity cleaning

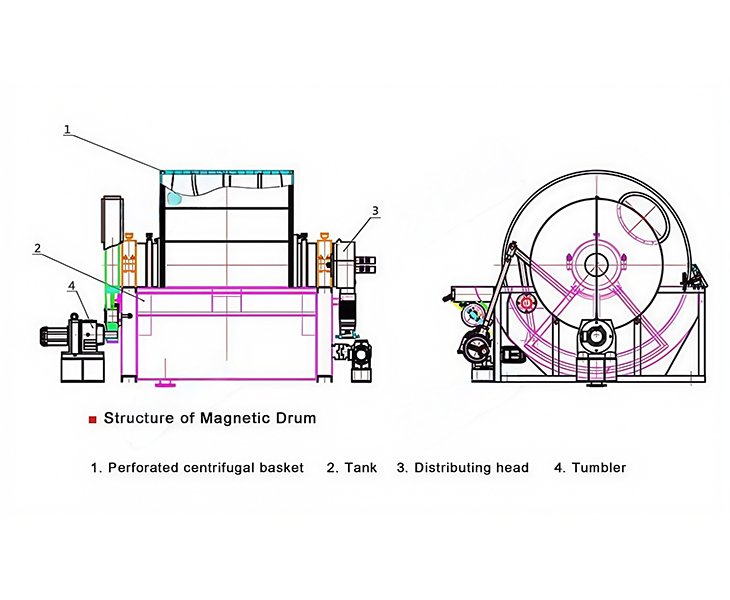

What Is Magnetic Drum

Sandreck Magnetic Drum is a dry magnetic separation equipment for pre-selection of coarse-grained strong magnetic minerals. Unless the magnetic impurity stone is removed, or the iron ore recovered from the waste rock is selected with a particle size of less than 300mm, the output is 100t/h-350t/h. Usually, an appropriate amount of tailings can be discarded to improve the grade of the mill.

The large magnetic wrap angle design, the magnetic wrap angle <180° increases the length of the separation belt and the number of magnetic flips, and realizes the effective separation of magnetic minerals and non-(weak) magnetic minerals. Sandreck is a source Magnetic Drum manufacturer and supplier in China. Our factory now has a wide range of magnetic separators for sale at preferential prices, and is equipped with professional engineers to provide you with customized procurement solutions.

Magnetic Drum Advantages

Robust design with minimal moving parts reduces downtime and maintenance costs.

Ensures maximum extraction of valuable magnetic materials, boosting productivity.

Allows for automated, uninterrupted processing in large-scale mining operations.

Uses less power compared to alternative separation methods, lowering operational costs.

Can be tuned to target different minerals, enhancing flexibility in processing various ores.

Reduces the need for chemical processing, minimizing pollution and waste.

Magnetic Drum Application

Magnetite pre-selection: Tailings throwing rate of 30% ↑, the grade into the mill from 25% to 35% soared.

Waste rock gold panning: 18% more iron ore concentrate recovered from waste rock pile, tailings turned into cash flow.

Steel mill waste: 91% recovery rate of iron particles in steel slag, generating more than 6 million dollars in annual income.

River dredging: Rapid extraction of river sediment magnetite, 2,000 tons per day.

More About Our Company

- Technical Parameters

| Model | Barrel Diameter (mm) | Barrel Length (mm) | Belt Width (mm) | Field Strength of Barrel Gauge (mT) | Capacity (t/h) | Feed Size (mm) |

| CTGG-0812 | 800 | 1200 | 1000 | 300~500 | ≤100 | ≤200 |

| CTGG-0814 | 800 | 1400 | 1200 | 300~500 | ≤120 | ≤200 |

| CTGG-0816 | 800 | 1600 | 1400 | 300~500 | ≤150 | ≤200 |

| CTGG-0818 | 800 | 1800 | 1600 | 300~500 | ≤180 | ≤200 |

| CTGG-1018 | 1000 | 1800 | 1600 | 300~500 | ≤270 | ≤250 |

| CTGG-1218 | 1200 | 1800 | 1600 | 300~500 | ≤350 | ≤300 |

Sandreck is a Magnetic Drum Table manufacturer, integrating manufacturing, production and supply in one. We have a professional after-sales team, there are original parts to provide, maintenance costs are very low.

Sandreck have a dedicated production team. The delivery time of our Magnetic Drum is generally made within 20 days after the contract is signed.

You can send us a message on WhatsApp(+86 +13666293477) or leave your contact details on our website,later our online customer service will contact you and offer the price of our Magnetic Drum.