Jig

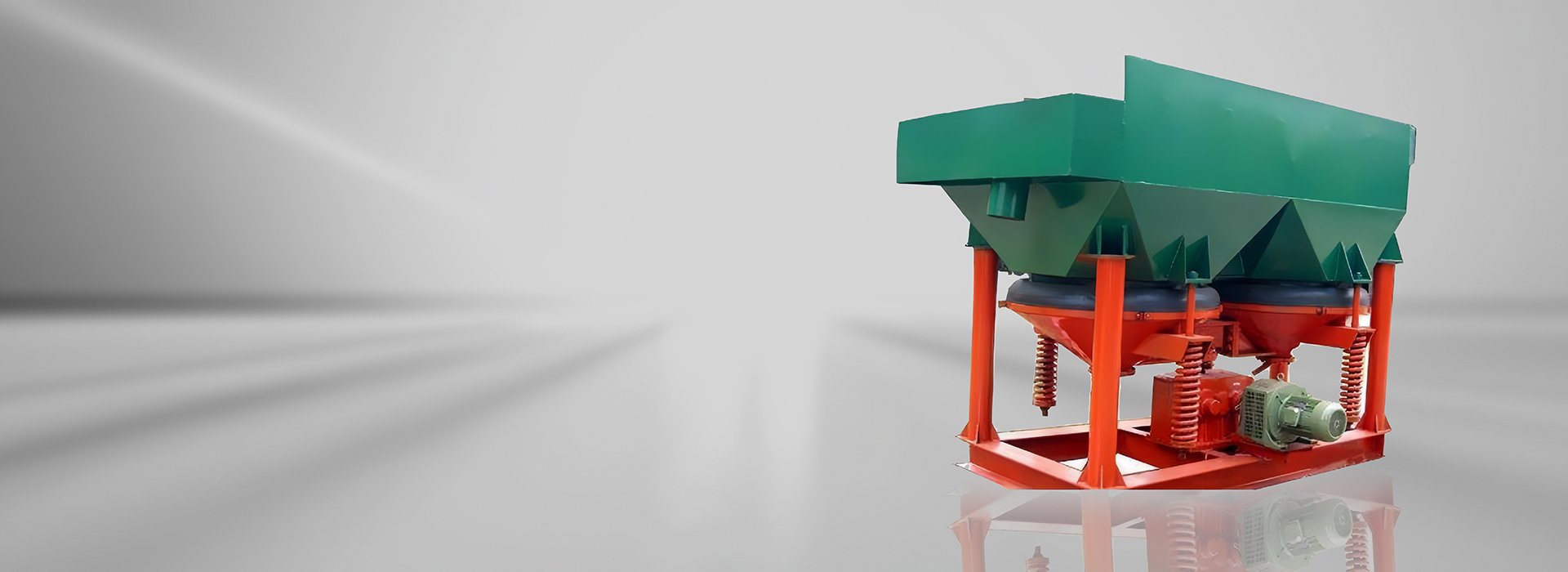

Sandreck Jig Efficiently separate coarse-grained ore materials and finely process fine-grained metal ores.

- Multi-mineral processing

- Wide particle size coverage

- Flexible adaptation to different scenarios

What Is Jig?

Sandreck Jig uses vertical alternating water flow to accurately separate light and heavy minerals which can be suitable for the sorting of metal placers such as tungsten, gold, and tin. It can easily handle 6-8mm coarse particles and can also finely sort fine particles. Whether it is to improve the recovery rate or the ore grade, Sandreck Jig can provide reliable support for your mineral processing process.

Sandreck Jig Advantages

A single device can process up to 50 tons/hour and supports mineral sorting as coarse as 35mm.

Suitable for more than ten kinds of metal ores and can handle both coarse and fine particles.

Electromagnetic speed control motor can be controlled with one button, and the sorting speed can be adjusted.

Only 10m² is occupied (50 tons/hour model), maintenance is simple, and operating cost is low.

Optimize water flow design, improve ore grade and recovery rate, and make fuller use of resources;

The factory has a large production scale, our jig is all at factory prices, which are economical and affordable.

Application Scope

Sandreck Jig is suitable for roughing, concentrating and grading of tungsten ore, gold ore, cassiterite, hematite, limonite, manganese ore, tantalum, niobium and other polymetallic ores, which can efficiently extract high-grade concentrate and improve the comprehensive utilization rate of associated ore resources.

More About Our Company

- Technical Parameters

| Model | Jigging Chamber | Diaphragm | Feed Size (mm) | Adding Water Yield Under Screen (m3/t) | Make-up Water Pressure (MPa) | Capacity (t/h) | Power (kw) | Overall Dimension (mm) | ||

| Shape | Area (m²) | Stroke (mm) | Jig Frequency (time/min) | |||||||

| JT-0.57 | Trapezoid | 0.57 | 8.5~12 10~17 12~21 | 80~180 | <6 | 1~2 | >0.05 | 1.5~3 | 1.5 | 1550x780x1530 |

| JT1-1 | Trapezoid | 1.04 | <10 | 2~3 | 2.5~5 | 2.2 | 2270x1110x1890 | |||

| JT2-2 | Rectangle | 2.28 | <10 | 2~4 | 5~10 | 3 | 3225x1550x2050 | |||

| JT3-1 | Trapezoid | 3 | 12~30 | 50~125 | <10 | 3~6 | >0.05 | 7.5~15 | 5.5 | 2745x2000x3030 |

| JT4-2 | Rectangle | 4 | 25~57 | <25 | 4~8 | 8~20 | 7.5 | 4240x1990x2750 | ||

| JT4-2A | Rectangle | 4 | 25~57 | <25 | 4~8 | 8~20 | 4×2 | 4240x1990x2750 | ||

| JT5-2 | Trapezoid | 4.86 | 12~30 | <10 | 3~6 | 12~25 | 7.5 | 3600x2000x2600 | ||

We are a manufacturer of Jig, integrating manufacturing, production and supply in one. We have a professional after-sales team, there are original parts to provide, maintenance costs are very low.

Sandreck have a dedicated production team. The delivery time of our Jig is generally made within 20 days after the contract is signed.

You can send us a message on WhatsApp(+86 +13666293477) or leave your contact details on our website,later our online customer service will contact you.