Dry Magnetic Separator

Dry Magnetic Separator is mainly used to separate large, coarse-grained strong magnetic ore and fine-grained weak magnetic ore.

- Pre-selection of Poor Magnetite

- Balance Payment Re-selection

- Magnetite Rich Concentration

- Steel Slag Recycling

What Is Dry Magnetic Separator

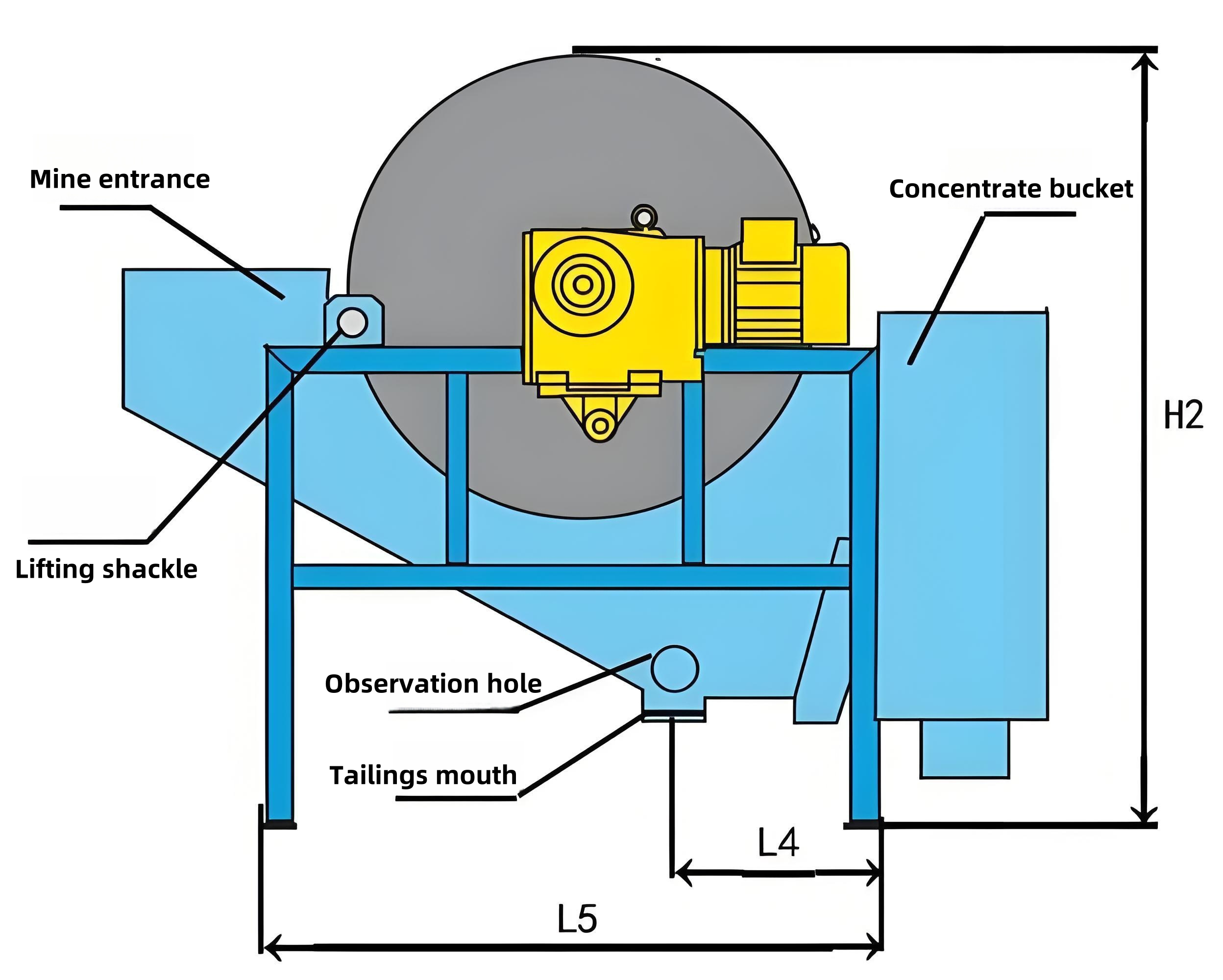

Sandreck Dry Magnetic Separator absorbs international advanced technology and is designed for magnetite with a particle size below 30mm. It is suitable for pre-selection of poor/rich magnetite, tailings recovery, and slag treatment. Through innovative magnetic system structure and sorting technology, it can significantly increase the mill grade by 1-8.7%, and the tailing rate by 30%, helping you reduce the beneficiation cost by more than 40%, while solving the problems of eddy current heating and sticking ore of traditional equipment.

Sandreck is a professional Dry Magnetic Separator manufacturer and supplier. Our factory currently has a wide range of equipment for sale at a favorable price, and is equipped with professional engineers to develop a one-stop procurement plan for you. Worry-free for your production.

Dry Magnetic Separator Advantages

By leveraging this full circumferential magnetic coverage, our machine delivers superior recovery rates and operational reliability.

Magnetic flip + magnetic stirring dual action, Sandreck Dry Magnetic Separator’s mineral loss rate reduced to less than 0.3%.

The separator cylinder of this device is coated with 8mm special rubber, and the service life is three times longer than traditional one.

The eccentric magnetic system achieves 90% automatic shedding, and cooperates with the secondary unloading system.

Sandreck Dry Magnetic Separator’s Pre-selection tailings reduce 30% , and the comprehensive cost is reduced by 40%.

The tailings are reduced by more than 35%. By optimizing mineral recovery and minimizing waste, this system cuts operational expenses.

Why Choose Sandreck Dry Magnetic Separator?

Sandreck is a professional Dry Magnetic Separator Equipment manufacturer and supplier. Our factory currently has a wide range of equipment for sale at a favorable price, and is equipped with professional engineers to develop a one-stop procurement plan for you. Worry-free for your production.

More About Our Company

- Technical Parameters

Model | CTXG-0606 | CTXG-0812 | CTXG-0818 |

| Diameter(mm) | 600 | 800 | 800 |

| Length(mm) | 600 | 1200 | 1800 |

| Field strength(mT) | 300~500 | 300~500 | 300~500 |

| Feed Size(mm) | -30 | -30 | -30 |

| Moisture content | ≤5% | ≤5% | ≤5% |

| Capacity(t/h) | ≤35 | ≤100 | ≤150 |

| Power(KW) | 5.5×2 | 11×2 | 11×2 |

| Weight(t) | 2.9 | 5.8 | 7.9 |

| External Dimension(mm) (L x W x H) | 2700×1700×1900 | 3400×2000×2100 | 4200×2000×2100 |

We are a Dry Magnetic Separator manufacturer, integrating manufacturing, production and supply in one. We have a professional after-sales team, there are original parts to provide, maintenance costs are very low.

Sandreck have a dedicated production team. The delivery time of our Dry Magnetic Separator is generally made within 20 days after the contract is signed.

You can send us a message on WhatsApp (+86 13666293477) or leave your contact details on our website, later our online customer service will contact you.