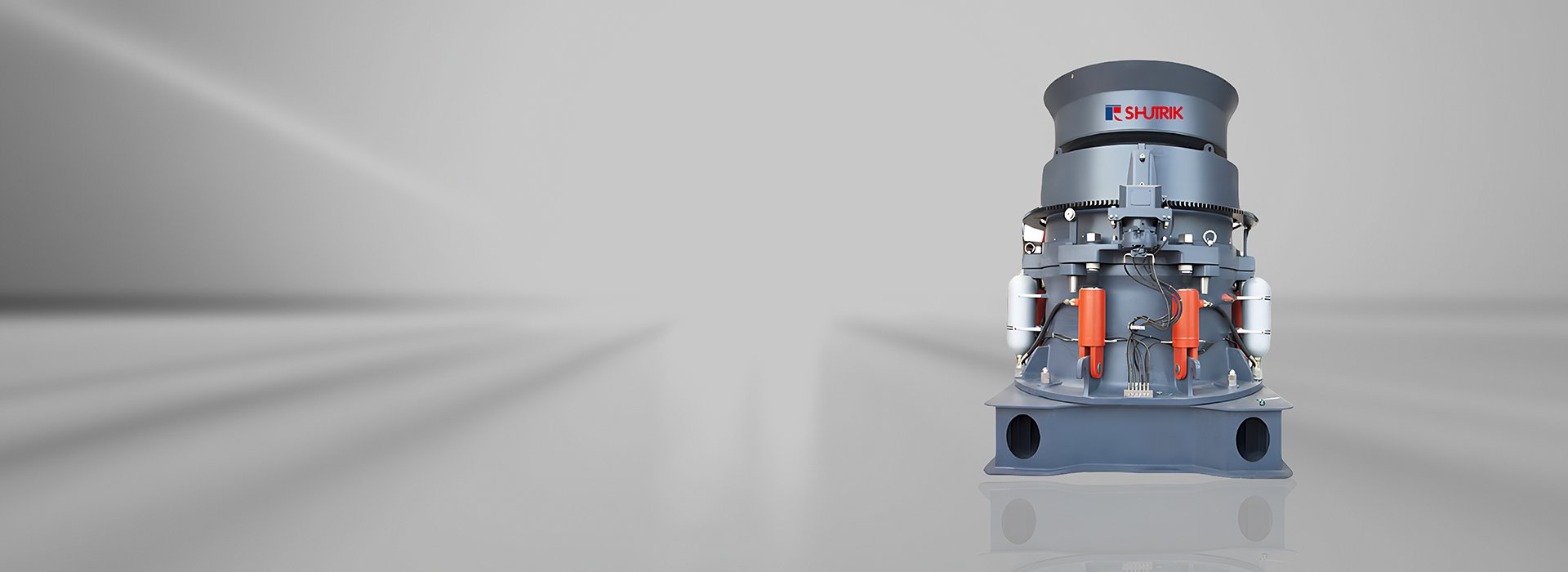

Cone Crusher Factory

The Cone Crusher is a robust and efficient crushing machine designed for reducing hard and abrasive materials into smaller, uniform particles.

![]() Allows precise control over particle size, making it versatile for various applications.

Allows precise control over particle size, making it versatile for various applications.

![]() Built with wear-resistant materials to ensure long service life and reduced maintenance.

Built with wear-resistant materials to ensure long service life and reduced maintenance.

![]() Delivers powerful performance with optimized speed and stroke for maximum productivity.

Delivers powerful performance with optimized speed and stroke for maximum productivity.

Your Expert Cone Crusher Supplier In China

Sandreck Cone Crusher is a high-performance crusher that absorbs modern technology and combines the performance of metal materials. It mainly achieves efficient crushing of materials by rotating the shaft and the cone swinging under the action of the eccentric shaft. It is the first choice to meet your high-quality finished product needs.

Sandreck Cone Crusher is divided into three series: HST Single-cylinder Cone Crusher, HPT Multi-cylinder Cone Crusher, and CS Spring Cone Crusher. The variety is complete and can be configured according to your needs.

We are the source factory of Cone Crusher manufacturers. The coarseness and fineness of the materials produced by our Cone Crusher can be adjusted to better meet your coarse crushing, medium crushing and fine crushing process needs, and realize one machine for multiple uses.

Product By Features

Sandreck HST Cone Crusher has unique advantages in crushing the hard ore, river pebbles, construction waste , etc.

HPT Cone Crusher breaks multiple hydraulic cylinders to adjust dynamic clearance and reduce downtime.

CS Cone Crusher adopts alloy spring as overload protection system to effectively protect the safety of equipment.

Cone Crusher Advantages

It can crush various soft and hard materials and is an ideal choice for secondary, tertiary and more crushing stages.

Crush the material into cubes with high fine particle content to meet your high-quality construction aggregate needs.

It has a variety of crushing chambers, and the chamber type can be changed by simply replacing the liner.

Equipped with PLC control system, remote control, one-button start and one-button stop can be realized.

Our Cone Crusher adopts a dual safety hydraulic control system to achieve full lubrication and overload protection.

It has fewer replacement parts and a long service life, saving you the cost of later operation and maintenance.

One Crusher, Multiple Applications

The Sandreck Cone Crusher provides simple crushing options: it can independently complete medium crushing, fine crushing and ultra-fine crushing tasks, which meets the requirements of medium scale production.

Our Cone Crusher can also be utilized as a core piece of machinery, working with Jaw Crushers, Sand-Making Machines, etc. to form an automated high yield crushing and screening production line.

Crushing newbies, don't worry!

Company Advantage

Sandreck is a Cone Crusher Manufacturing corporation with integrated R & D and design, production and sales. It has over 100 sets of various specifications of machining equipment, such as CNC vertical lathes, deep hole drilling machinery, laser cutting machines, planers, CNC lathes, CNC boring and milling machines, etc.

We are a Cone Crusher corporation. Our crushing equipments are used in all parts of the world for the reason that we will provide you professional solutions and mature supporting design plans based on your needs to bring you the most value.

Cone Crusher Parts

Sandreck strictly controls the quality of every Cone Crusher Components, ensuring your satisfaction with the product.

Sandreck Cone Crusher Frames are engineered with superior strength and precision, ensuring perfect alignment and unwavering stability under extreme operating conditions. This maximizes crushing force and dramatically extends the life of your entire machine.

Sandreck’s engineers not only pay attention to the structural optimization of Cone Crusher, but also pay attention to the wear resistance of core components such as rolled mortar wall and lining plate, all of our components are made of high manganese steel wear-resistant materials to save you later maintenance costs

We provide constant gear engagement and rotational stability under high loads. This reduces vibration, protects against premature wear, and ensures your Cone Crusher has optimal functioning efficiency for maximum productivity and uptime.

Sandreck Cone Crusher Hydraulic Cylinder can precisely control the discharge opening width of the crushing cavity in order to control the product size, and it also provides consistent and stable hydraulic thrust to maintain output of continuous and effective crushing force.

Cone Crusher Cases

Sandreck is a well-known Chinese integrated supplier of crushed stone equipment and solutions, and has provided services for over a thousand sand and gravel processing plants.

Processing material: granite

Capacity: 200-300 t/h

Configuration: Jaw Crusher + Cone Crusher + Vibrating Screen

Processing material: Cobblestone

Capacity: 150-200 t/h

Configuration: Jaw Crusher + Cone Crusher+Vibrating Screen

Processing material: quartz

Capacity: 200-400 t/h

Configuration: Jaw Crusher + Cone Crusher

Processing material: Pebble

Capacity: 400 t/h

Finished size: 12 stone, 13 stone, mechanism sand

Testimonials

Lubrication systems are used to reduce friction, cool components, prevent wear and corrosion, and ensure proper operation of equipment.

The Hydraulic Cone Crusher is adjusted by the hydraulic system, and the Spring Cone Crusher is achieved by adjusting the spring pressure or replacing the liner.

The spare parts replacement cycle depends on the hardness of the material and the frequency of use, usually ranging from a few months to a year.

Related Product

Efficient mobile crushing station integrating crawler self-moving chassis and Cone Crusher.

Our Mobile Cone Crusher is mainly composed of hydraulic electronic control system.

Classification equipment that separates solid particles by size or density.

Sandreck Flotation Cell is a high efficiency mineral sorting equipment suitable for coarse mining.

Continuously transport materials or products, ensure the operation of automated assembly lines.