Belt Conveyor

The Belt Conveyor offers high-load capacity, smooth and efficient material transport, and low maintenance, making it ideal for bulk handling in various industries.

![]() Feed size: ≤500mm

Feed size: ≤500mm

![]() Power: 5.5-37kw

Power: 5.5-37kw

![]() Output: 50-500t/h

Output: 50-500t/h

What Is Belt Conveyor?

Belt Conveyors work on the principle of friction transmission, giving continuous loading material from the feed point to the discharge point, giving the most efficient economic system of material handling. They have high throughput, can be carried over long distances, and work with complete stability.

Sandreck Belt Conveyor is produced with durable frames, belts, rollers and tensioning systems to seamlessly adapt to long-distance bulk transport and short connecting lines. It is widely used in material transmission systems in mining, building materials, metallurgy and other industries. It is onnected to crushing and screening equipment to efficiently transport crushed stone and sand materials and reduce manual intervention.

Sandreck Belt Conveyor Advantages

Supports long-distance and large-scale operations, with an average daily conveying volume of up to 10,000 tons.

Resistant to high and low temperatures, impact and corrosion resistance, and adaptable to responsible working conditions.

Modular design allows quick disassembly — adapts to horizontal/inclined layouts and terrain/process needs.

Built with wear-resistant, flame-retardant materials, our conveyor extends key component lifespan by 30%+.

Integrates broken belt capture, salt spray monitoring and emergency braking to ensure safety and reduce risk.

As a Chinese manufacturer, Sandreck factory offers the most reasonable price for each Belt Conveyor.

Stable & Reliable

Sandreck Belt Conveyors are fitted out with self-centering idler sets, to guard against belt misalignment effectively. This is promoted by the performance stability over long distances and under heavy loads which is guaranteed, and, therefore, downtime and damage to productivity is minimized.

Varying Design Structures

Sandreck Belt Conveyors are available in trough, flat and inclined form, as well as various optional extras such as cleats and side skirts. At all times, whatever the case may be; Sandreck has a service solution to meet your specific requirements for conveying.

Safety and Convenience

Sandreck Belt Conveyors come standard with inspection platforms, protective covers, discharge hoppers, and other functional components. These features enhance operational safety and simplify daily maintenance, ensuring reliable and worry-free operation.

Belt Conveyor Case Diagram

As a leading integrated supplier of sand and gravel Aggregate Conveying Equipment and solutions in China, Sandreck has served over a thousand sand and gravel processing plants.

More About Our Company

- Technical Parameters

| Belt Width (mm) | Transmission Length Power (m)/(kw) | Conveying Speed (m/s) | Transport Capacity (t/h) | ||

| B650 | ≤12/4 | 1-20/4-5.5 | 20-30/5.5-11 | 1.25-2.0 | 80-120 |

| B800 | ≤6/4 | 10-15/4-5.5 | 15-30/5.5-15 | 1.25-2.0 | 120-200 |

| B1000 | ≤10/5.5 | 10-20/5.5-11 | 20-40/11-22 | 1.25-2.0 | 200-320 |

| B1200 | ≤10/7.5 | 10-20/7.5-15 | 20-40/15-30 | 1.25-2.0 | 320-480 |

Testimonials

We are a Belt Conveyor manufacturer, integrating manufacturing, production and supply in one. We have a professional after-sales team, there are original parts to provide, which means the maintenance costs are very low.

Sandreck have a dedicated production team. The delivery time of Sandreck Belt Conveyor is generally made within 20 days after the contract is signed.

You can send us a message on WhatsApp (+86 13666293477) or leave your contact details on our website, later our online customer service will contact you to give you the information of our Belt Conveyor.

Related Products

Used in fine crushing operations, can be used for primary and secondary crushing.

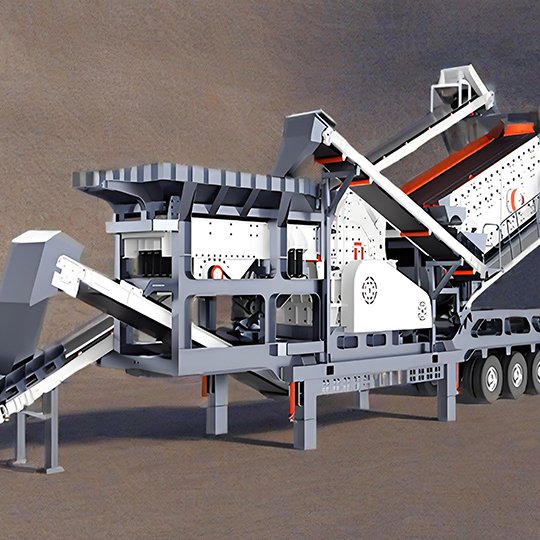

Equipped with high-performance Impact Crusher and Screening equipment.

Modular mobile equipment developed to meet the needs of users for large crushers.