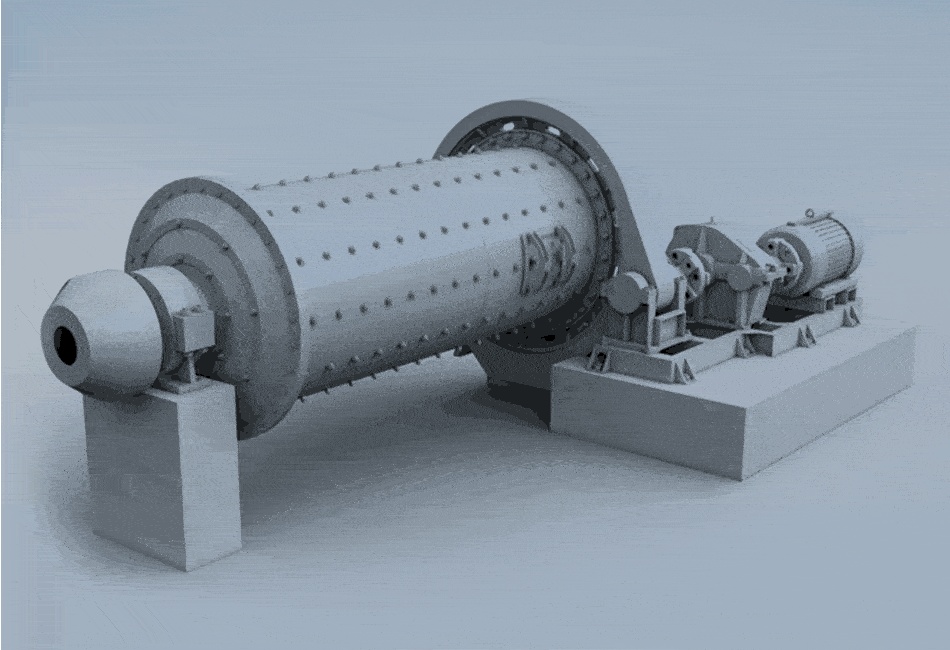

Ball Mill

Ball Mill is the main piece of grinding equipment after crushing.

- Feed size: ≤18MM

- Motor power: 22-380 KW

- Processing capacity: 0.5-50 T/H

Your Expert Ball Mill Supplier in China

Sandrec is a reputable manufacturer of Ball Mills in China that exports a wide range of strong, energy efficient and operationally efficient ball milling equipment for cement, mining, ore processing, and other industries.

Ball Mills are widely used as key equipment for secondary grinding after crushing. Our ball mills are exceptionally powerful grinding machines on their own but with agitation modeled on real agitator functions consequently provide finer and more uniform grinding.

Our equipment is widely used in a variety of industries such as ferrous and non-ferrous metal mining, coal, transportation, , and we provide solutions that meet the personalized grinding needs of different customers.

Product By Features

To meet the needs of various production scenarios, we offer a wide range of product options:

By Grinding Method: Dry Ball Mill, Wet Ball Mill

By Layout: Grate Ball Mill, Overflow Ball Mill

Are operated without any liquid as a medium, are used for drying materials, reduction of dust, and are utilized for dry ore separation.

Operate with a liquid as a medium, are used for moist materials, increases fineness, are used for wet smelting, etc.

Featuring a simple structure and more complete grinding, it is suitable for fine grinding requiring a finer product.

With fast discharge speed and high output, It is suitable for coarse grinding or over grinding applications.

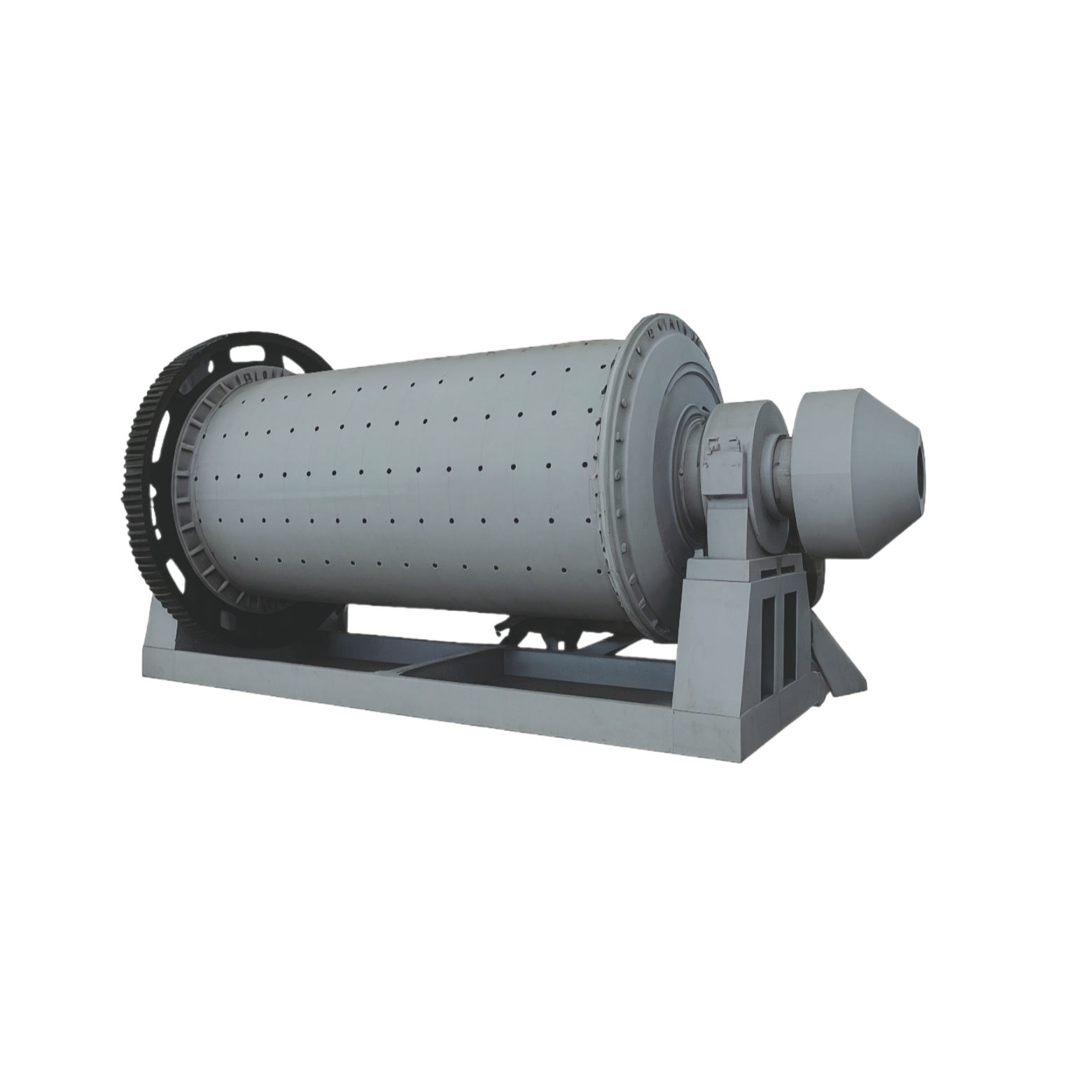

Ball Mill Advantages

The convertor uses double-row spherical roller bearings, reduces friction and save about 30% energy.

Light weight and wear-resistant materials make it durable and prolonging its service life.

The discharge port of the Ball Mill is large, and the production capacity is high.

We provide diverse Ball Mill design options, can meet any kinds of requirements.

Sandreck’s Ball Mill has an oil mist lubrication system of large and small gears.

Applicable to different properties of materials, can meet the needs of different grinding.

Ball Mill Application Range

The Ball Mill is suitable for gold, copper, magnetite, kaolin, mica, clay, etc. It can easily adapt and become your stable partner in the mineral processing production line.

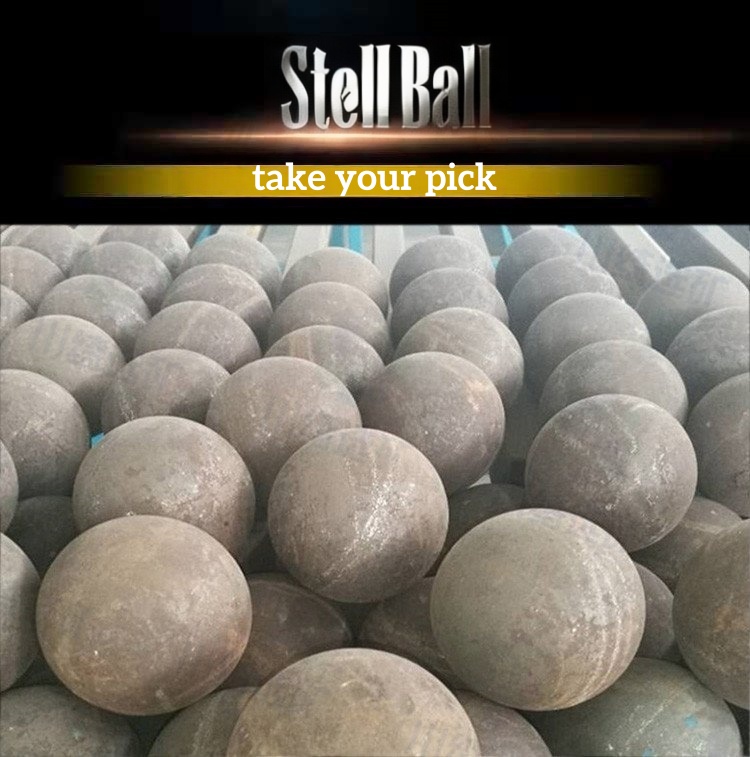

Ball Mill-High Chrome Steel Balls

As a leading Ball Mill manufacturer in China, Sandreck uses HRC 60+ high chrome material to increase the abrasion resistance of ball mill grinding media “steel balls”, which can reduce the replacement cost of ore grinding by 40%.

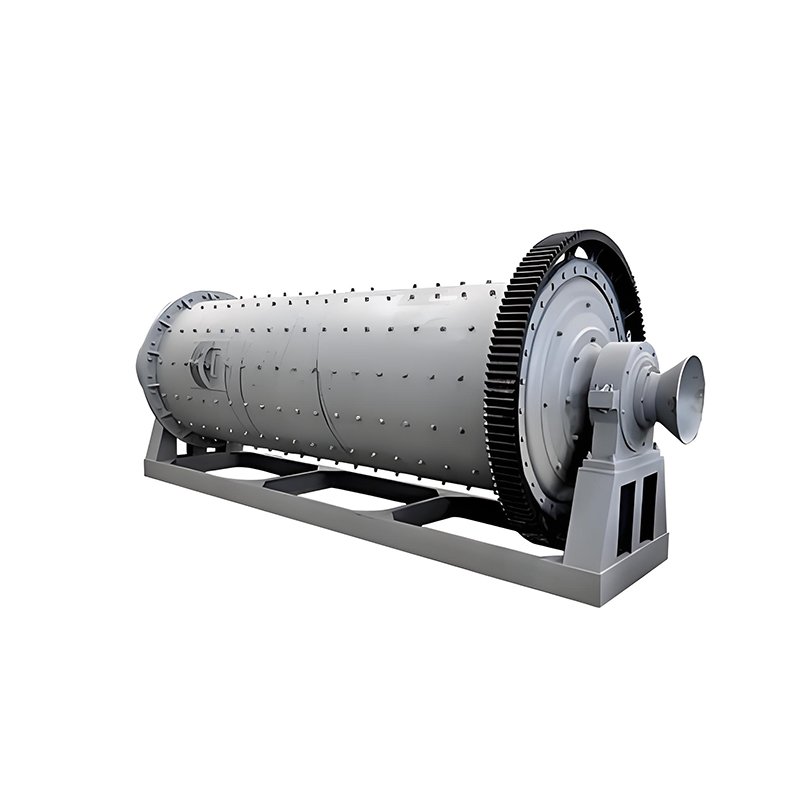

Dual-Axis Aupport For Stable Operation

Sandreck ball mills are built for stability and flexibility on the fundamental structure:

1. The end caps are one piece casting for strength and sealing ability to help minimize leaks and dust. The end caps are bolted to the ball mill by high strength bolts, requiring little maintenance.

2. Each end cap has trunnions attached, that provide dual axis support: the feed end is fixed and the discharge is floating. This design allows the ball mill to operate under low noise and wear, allowing for longer mill life.

Ball Mill Parts

Sandreck Ball Mills have a cylinder steel plate of .>16mm thickness to avoid deformation; the liner is high-manganese steel or rubber, depending on the material.

Our Ball Mills use the national standard hardened gear reducer which saves between 10%-15% than the standard reducer.

Our base uses a welded steel structure that encompasses

mounting points for all critical components, consists of adjustable bolts and anchor holes to eliminate vibration and misalignment.

Our ball mills use self-aligning main bearings to automatically adjust for minor misalignment.

More About Our Company

- Technical Parameters

Model | Cylinder Speed(r/min) | Ball Loading(t) | Feed Size(mm) | Discharge Size (mm) | Yield(t/h) | Motor Power(kw) | Weight(t) |

Φ900*1800 | 38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| Φ900*3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| Φ1200*2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 12.5 |

| Φ1200*3000 | 32.4 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Φ1200*4500 | 29.7 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| Φ1500*3000 | 27 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| Φ1500*4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 90 | 21 |

| Φ1500*5700 | 27 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 132 | 24.7 |

| Φ1830*3000 | 24 | 11 | ≤25 | 0.074-0.4 | 4-10 | 180 | 28 |

| Φ1830*6400 | 24 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

| Φ1830*7000 | 24 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

| Φ2200*4500 | 21 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

| Φ2200*6500 | 21 | 35 | ≤25 | 0.074-0.4 | 14-26 | 370 | 52.8 |

| Φ2200*7500 | 21 | 35 | ≤25 | 0.074-0.4 | 16-29 | 380 | 56 |

When using a Ball Mill, please ensure that the grinding media is configured correctly, the material feed is uniform, and avoid overloading or idling.

Usually, the spare parts’ replacement cycle ranges from 6 months at the beginning to several years. Mid-term maintenance depends on the material and the wear.

Sandreck is a Chinese Ball Mill supplier with very reasonable price. Our cheap price Ball Mill has a real wide range using in the world. You can contact us via WhatsApp (+8613666293477), or leave your message on this page.