Rock Crusher

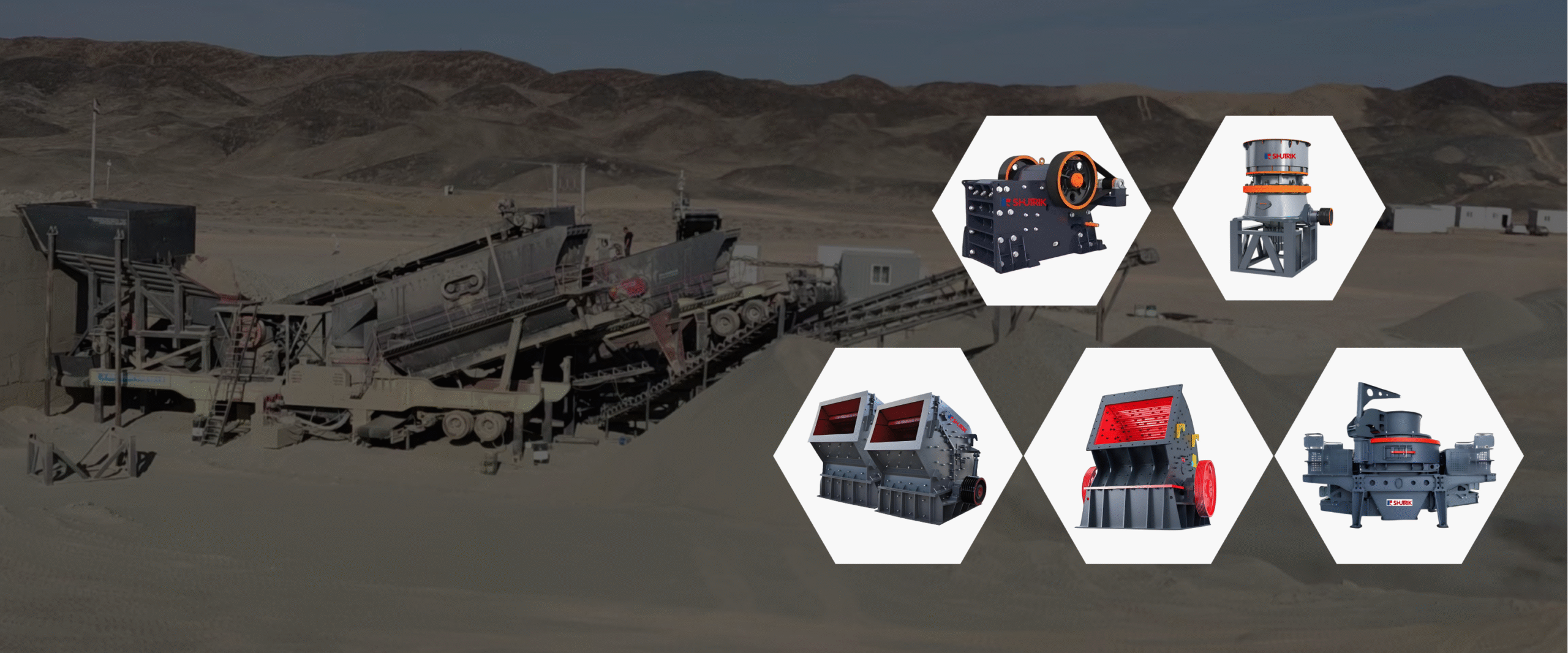

Sandreck Rock Crushers are core equipment in the mining and construction industries, dedicated to efficiently transforming large rocks into precisely sized aggregates and sand.

![]() As a professional Rock Equipment Manufacturer:

As a professional Rock Equipment Manufacturer:

![]() Expertly processing various materials including rock, ore, and construction waste.

Expertly processing various materials including rock, ore, and construction waste.

![]() Supporting standalone operation or can be combined with other Rock Crushers to form a complete production line.

Supporting standalone operation or can be combined with other Rock Crushers to form a complete production line.

We offer both stationary and Mobile Rock Crusher types to comprehensively meet different operational needs.

Your Trusted Chinese Rock Crusher Manufacturer

Sandreck is a professional Rock Crusher manufacturer in China. Based in China’s core industrial zones, we directly source special steel and top-tier electrical controls, ensuring high performance and long service life for our Rock Crusher equipment, directly saving you over 15% in comprehensive costs.

Our Rock Crushers are backed by data: 100% pass rate for critical welds, and every machine undergoes an 8-hour load test before leaving the factory, making quality unmistakable.

We have built an efficient global support network for Rock Crusher users. With three major spare parts centers in Asia, Europe, and the Middle East, we stock over 95% of commonly worn Crusher Parts.

We provide 7×24 multilingual technical support and commit to delivering solutions for your Rock Crushing Equipment within 24 hours when needed, ensuring continuous and stable operation of your crushing processes.

Types of Rock Crushers

Our company offers a wide variety of Rock Crushers that can flexibly adjust depending on the material characteristics and the desired particle size, allowing the full process of crushing to occur from coarse-to-fine effectively.

The Jaw Crusher uses the squeezing effect between the movable jaw and the fixed jaw to accomplish the primary crushing of materials whose size is large.

The Cone Crusher employs a laminated crushing principle, suitable for secondary/fine crushing applications of medium-hard to extremely-hard materials.

Utilizes the high-speed impact of hammers to strike materials, which then rebound and collide with the impact plates, achieving secondary crushing, fine crushing, and shaping.

The Hammer Crusher relies on high-speed impacts of hammers to strike and break materials, suitable for medium and fine crushing of brittle materials.

The Box Crusher operates using liner-compression and impulse of hammer to compress and crush the materials, suitable for coarse and medium crushing of various materials.

Operates by using a high-speed rotating impeller to throw and collide materials for crushing, specializing in sand shaping and manufactured sand production.

The double-roll crusher is a type of efficient crushing equipment that produces medium and fine crushing of materials via the squeezing

Classification of mobility methods

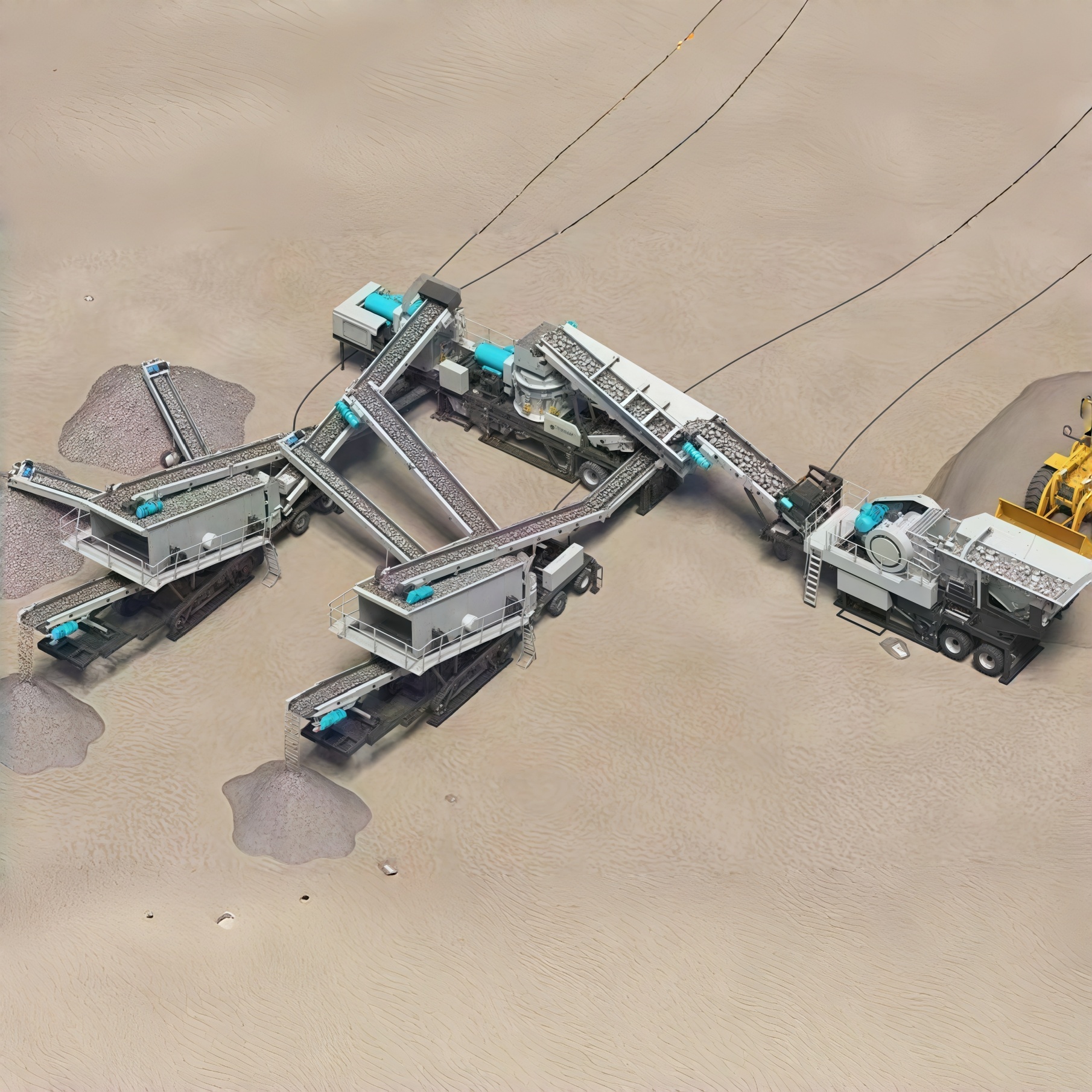

Mobile Rock Crusher

Mobile Rock CrusherThe Crushing Equipment is integrated onto a tyre chassis, enabling flexible relocation and suitability for construction waste processing and on-site crushing in mining operations.

Crawler Rock Crusher

Crawler Rock CrusherThe Crawler Mobile Crushing Plant uses tracks as its running gear, allowing for a robust off-road capability with the ability to navigate more freely in complex terrain.

Modular Rock Crusher

Modular Rock CrusherThe Modular Mobile Crushing Plant consists of multi-functional modules, as well as allow for configure-able combinations if required, producing crushing/screen modules if necessary.

Advantages of Our Rock Crushers

Sandreck Rock Crushers feature optimized crushing chambers and drive systems, delivering higher output with equivalent energy consumption.

Our Rock Crushing Equipment utilizes top-grade wear-resistant materials, extending service life by 30% even in harsh operating conditions.

The modular design of Sandreck Rock Crushers significantly reduces maintenance costs and downtime.

Optional automation systems enable intelligent monitoring and diagnostics for Rock Crushing Equipment.

Advanced vibration damping and sealing technologies ensure low-noise operation, complying with international environmental standards.

Our Rock Crushing Equipment features adjustable discharge specifications to meet diverse production requirements.

Intelligent Crushing Chamber

Sandreck’s Rock Crushers feature an optimized crushing chamber design that perfectly combines lamination and impact crushing, increasing efficiency by more than 20% and producing aggregates with a cubic content of over 95%.

Modular Maintenance Design

Core components allow quick side or top access. Hydraulic opening systems halve the time for parts like plate hammer replacement, drastically cutting maintenance costs and downtime.

Hydraulic Maintenance System

Features a fully hydraulic system for one-click adjustment of discharge opening size and real-time operation monitoring. An automatic iron passing protection system releases and resets within 0.5 seconds upon encountering uncrushable material, safeguarding core transmission components.

New to This? No Worries.

Unfamiliar with Rock Crushing Equipment? Our technical team will first thoroughly understand your material properties, capacity needs, and site conditions to recommend the most suitable Rock Crusher Model.

Unsure about the Rock Crushers configuration details? We will provide the optimal layout and planning for your production line based on your budget and goals, ensuring maximum return on investment.

Concerned about subsequent operations? For your chosen Rock Crusher, we offer one-on-one guidance and training from installation and commissioning to daily maintenance, ensuring your team quickly becomes proficient.

Wide Range of Applications

Sandreck Rock Crushers serve as a crucial force in global infrastructure development. Our equipment is widely applied in the following key sectors:

Sandreck Rock Crushers efficiently process hard minerals such as iron ore and copper ore

our Rock Crushing Equipment professionally produces high-quality construction aggregates and road base materials

Sandreck Rock Crushers supply precisely graded concrete aggregates for dam construction

our Rock Crusher continuously provides high-standard subgrade fillers;

Sandreck Rock Crushers enable construction waste recycling

Rock Crusher Cases

Sandreck is a well-known Rock Crushing Equipment supplier in China, serving thousands of sand and gravel processing plants.

Material: Basalt

Output: 500 tons/hour

Main Units: Car 1: 1352 feeder, 1912 jaw crusher, 160 single-cylinder cone crusher, 12442 double-layer vibrating screen

Car 2: 1015 transfer feeder, 1145 impact crusher

Type: EPC General Contracting

Material: Silica

Output: 300 tons/hour

Finished Product: 50-80mm

Main Equipment: 69 Jaw Crusher, 950 Jaw Crusher, 3075 Three-Layer Vibrating Screen, 192 Bag Filter

Type: EPC General Contracting

Material: River Pebbles

Output: 400 tons/hour

Main Equipment: 660 cone crusher, 750 jaw crusher, 1263 impact crusher, 800 double-roll crusher, 3075 three-layer vibrating screen

Type:rent

Material: Rock

Output: 200 tons/hour

Finished size: 12 stone, 13 stone, mechanism sand

Configuration: 142 vibrating feeder, 3-layer 2170 vibrating screen, 421 impact crusher, belt conveyor

Testimonials

Our equipment handles materials with compressive strength ≤320MPa, adaptable from soft limestone (80-150MPa) to hard basalt (250-320MPa). Customized solutions are available based on material test reports.

We promise: door-to-door logistics and customs clearance support, assigned engineers for on-site installation and training, one-year warranty, and rapid repair support from overseas service centers.

Absolutely. Before you decide to purchase, we will confirm and customize the power system according to your country’s voltage standards (e.g., 110V/220V/380V/440V) and frequency (50Hz/60Hz). Diesel power options are also available for sites without stable electricity.