Introduction

Mineral Processing (Beneficiation) is the critical process of upgrading raw ore into high-grade concentrates. When you select the right equipment, it directly impacts your recovery rates, operational costs, and environmental sustainability.

How to Choose The Right Machinery for Your Needs? This guide explores the equipment landscape and provides actionable strategies to help you match machinery to your ore’s unique characteristics.

Categories of Ore Dressing Equipment

Crushing and Screening

Crushers and screeners are first on the front line. Gyratory crushers are useful for hard, abrasive ores.

Their high reduction ratios will do wonders for your operation. Use modular trommel screens with adjustable meshes for changing clay content that can create blockages in sticky ore.

This can save you a lot of trouble if you’ve ever dealt with these situations before.

Gravity Separation

Gravity separation machines will be the level of efficiency in your recovery of ore.

Trapezoidal jigs can achieve throughputs up to 40–60 t/h for coarse ore, allowing you to maximize your throughput. For fine ore (<0.1 mm), advanced gravity separation machines, such as enhanced gravity separators, work in both centrifugal force and fluidized beds to help provide higher recoveries with fine ores, and help to obtain desired ore concentrations.

Automated multi-deck shaking tables with automated discharge are useful in largely continuous operations and will increase the amount of recoveries.

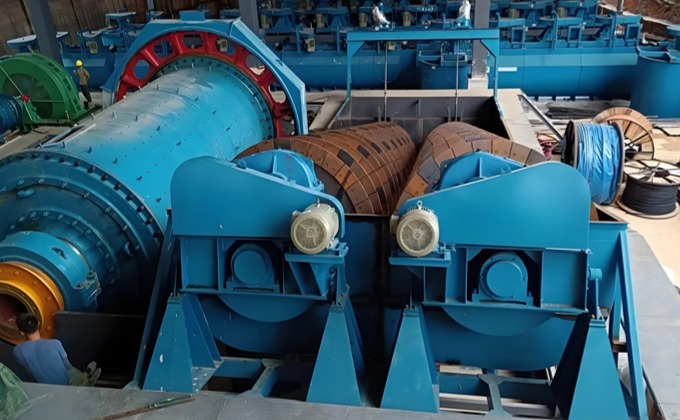

Grinding

Grinding mills allow you to navigate the line between fineness and cost. The overflow ball mill would allow you coarse grinding (product P80 >150 µm), while a grate discharge mill optimizes fine grinding (P80 <200 µm) depending on the application.

If you are contemplating high-purity applications, you may want to use ceramic linings and media to reduce iron contamination and oxidation.

Froth Flotation

Like other methods, complex flotation cells like mechanical agitators for high-sulfide ores and Jameson cells for fine-particle scavenging.

There is a range of pH control systems to provide ideal pH droplets for ore to be activated (pH 4.5–6.5).

This can increase the overall efficiency of the flotation process.

Dewatering and Tailings Management

Auxiliary equipment guarantees consistent flows in your process.

Centrifugal slurry pumps can handle abrasive feeds, and hydrocyclones to classify milled slurry- both will be critical pieces of equipment that assist in dewatering.

Automated thickener underflow sensors can provide useful consistency through assessing the pulp density in the thickener, basically removing another aspect of estimating if you need a fixed or underflow discharge.

Essential Considerations When Choosing Equipment

Choosing equipment is not a cookie-cutter exercise. Here’s what to pay attention to:

Ore Properties

The ore handler will dictate the equipment you need. If the ore is viscous, sticky, or a combination of the two, and could clog the crushers and griding mills, it will require different designs and anti-adhesion liners.

Ore with uneven particle size distributions can mean adjustable settings for crushers, and if it is low-grade ore remember to consider high-efficiency beneficiation equipment to maximize recovery.

Always conduct tests on your ore samples before settling on equipment selections to prevent wasting lots of money.

Production Scale

If you are a small operation – processing <500 tons/day – using smaller mobile equipment, including portable jaw crushers and batch-type flotation machines, can give you a balance of cost and flexibility.

Utility costs make up 30-40% of operational costs for a ore dressing operation. This means that starting with energy-efficient equipment can yield significant cost savings.

For larger operations (> 2,000 tons/day), you will need high throughput equipment – multi-stage cone crushers, continuous flotation lines, and/or high-capacity tubular ball mills – to achieve your target outputs at the right energy efficiency and throughput.

Energy Efficiency & Environmental Compliance

Legislation on energy consumption is becoming stricter, and you will need to include dust control systems (for crushers) and wastewater recycling (for flotation), which cannot be avoided.

For example, ensure equipment options include dust suppression or ways to recycle process wastewater. Make sure that you have built-in environmental friendly options on your plant, because you do not want to pay for expensive retrofits down the road.

Budget & Long-Term Maintenance

CommitmentEquipment is not just how much it costs initially. For example, if you acquire a low-cost crusher, you may end up with repair bills that fail to take into consideration the sourcing of parts.

Therefore, you should purchase equipment that has a spare parts availability, plus some local service commitment. As an example, Metso, or Sandvik, offer world-wide service networks that minimize your downtime.

When preparing your Pros and Cons of your equipment selection, you should calculate the entire Cost of Ownership (TCO) based on energy, repairs, downtime, labor support, and other costs over a life cycle of say 5 to 10 years.

Most Frequent Mistakes to Avoid

You could even read stories of experienced miners not getting it right in equipment selection. Let us help you avoid these mistakes:

Not testing ore: Just because a piece of equipment is supposed to work for “normal” ore, do not assume it will. Test your samples for hardness, mineralogy, and moisture.

Cost over performance: If you find a flotation machine cheap enough; it probably works cheap enough to not get you your recovery target with your ore. Therefore, from a loss of output perspective, you are losing more than you saved over time.

Not putting scalability into account: If you are going to take your mine from 500 ton/day to 2,000 ton/day, then do not think you will be working with small equipment, for long. Make sure you perform your due diligence in getting equipment that will upgrade or get added to in the future.

Future Trends in Ore Processing Equipment

The future of mineral processing equipment is poised to be defined by intelligent automation, green technology, and modular design to develop efficiency and sustainability for ore of all types.

AI-based smart systems will allow entire processing plants to optimise in real time by continuously characterizing the ore for proper setting of crushers, speed of mills, and differentiating conditions of separators.

Sensor-based sorting will be the new normal – implementing enhanced pre-concentration at coarser sizes using technologies such as hyperspectral imaging and X-ray transmission, while reducing energy-intensive grinding by as much as 30%.

In summary, the future of mineral processing will be characterized by enhanced efficiency and sustainability, with technology and process adaptability to accommodate the diverse ore bodies of the world.

Conclusion

As you can see, selecting the correct ore dressing equipment involves not just choosing your machinery, but also matching your machinery to ore characteristics, production requirements, and cost while also being conscious of efficiency and responsible operation.

Similar to what we discussed above, once you understand the types of equipment available and evaluate the essential factors, you will minimize risks and optimize returns.

Are you ready to further improve your plant’s ore dressing process? Speak with a mining equipment professional to develop a way to address your specific requirements!