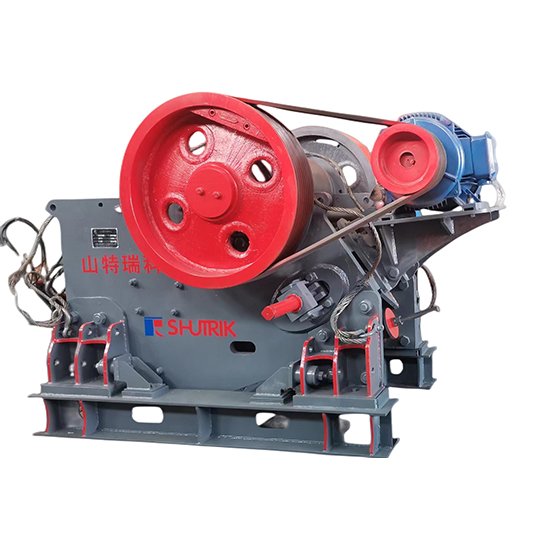

PEV Jaw Crusher

PEV jaw crusher is a widely used stone crusher.

- Feed size: 400-1200 mm

- Motor power: 55-300 KW

- Processing capacity: 50-1400T/H

Your Expert PEV Jaw Crusher Supplier In China.

Sandreck PEV Jaw Crusher is the main equipment of mining crushing.

Sandreck PEV Jaw Crusher have high-performance, heavy-duty crusher designed for primary crushing in mining, quarrying and recycling. The motor drives the eccentric shaft to drive the movable jaw to swing periodically, forming an extrusion chamber with the fixed jaw to squeeze and crush the material. It can easily crush ores, stones, river pebbles, slag and other materials with a compressive strength of ≤300MPa.

It is usually used in conjunction with cone crushers, impact crushers, sand making machines and other equipment. It is widely used in building materials, metallurgy and other fields. It is the preferred equipment for coarse crushing operations.

Sandreck PEV Jaw Crusher is designed for low energy consumption and high output, and can operate reliably in harsh environments. The equipment combines safety, easy maintenance and long-term durability, and is ideal for processing hard rock, ore and demolition gravel. Upgrade your crushing operations with PEV Jaw Crusher – its precision design can achieve the highest productivity and cost-effectiveness.

PEV Jaw Crusher Advantages

Sandreck PEV Jaw Crusher uses advanced movable adhered assembly and high manganese steel cast jaw plate, long service life.

The crushing chamber adopts a “V”-shaped structure, which makes the size of finished material more uniform.

Sandreck PEV Jaw Crusher adopt advanced crushing technology, accurate internal structure, and increase the crushing ability.

Adopts centralized lubrication system, which is safe and reliable, reducing the downtime and maintenance time.

The Sandreck PEV Jaw Crusher’s motor and frame are integrated, which reducing the start-up setup time of the whole machine.

The use of wedge adjustment has adjustable discharge port size in running or stopped equipment

Why Choose Sandreck PEV Jaw Crusher?

With modular non-welded design and wedge adjustment technology, Sandreck PEV Jaw Crusher improves the equipment capacity by 35% and with hydraulic overload protection and wear-resistant lining, the maintenance cost is greatly reduced.

Sandreck PEV Jaw Crusher Working Principle

The motor drives the movable jaw to rise, the angle between the toggle plate and the movable jaw increases, and the movable jaw plate is pushed close to the fixed jaw plate to crush the material.

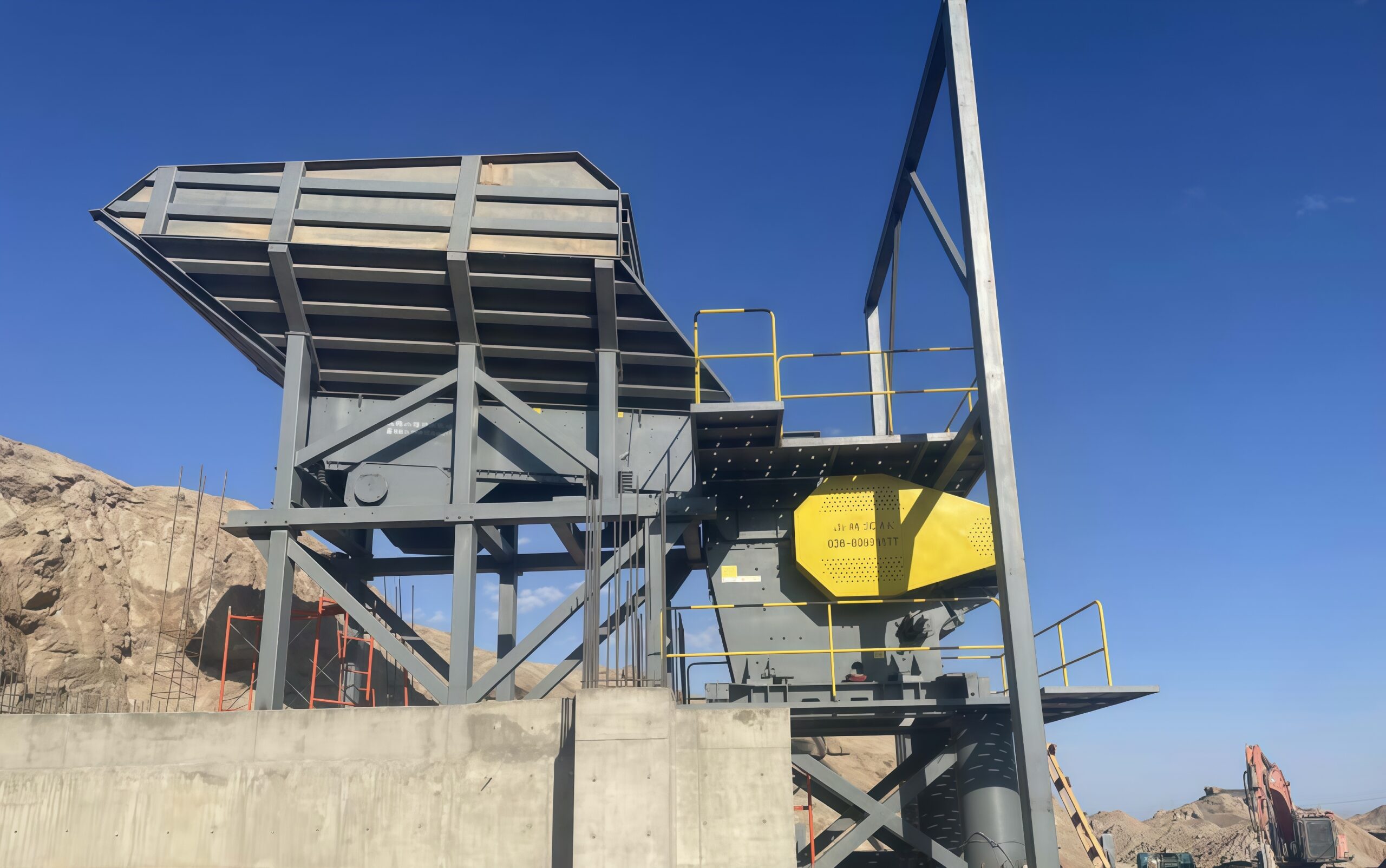

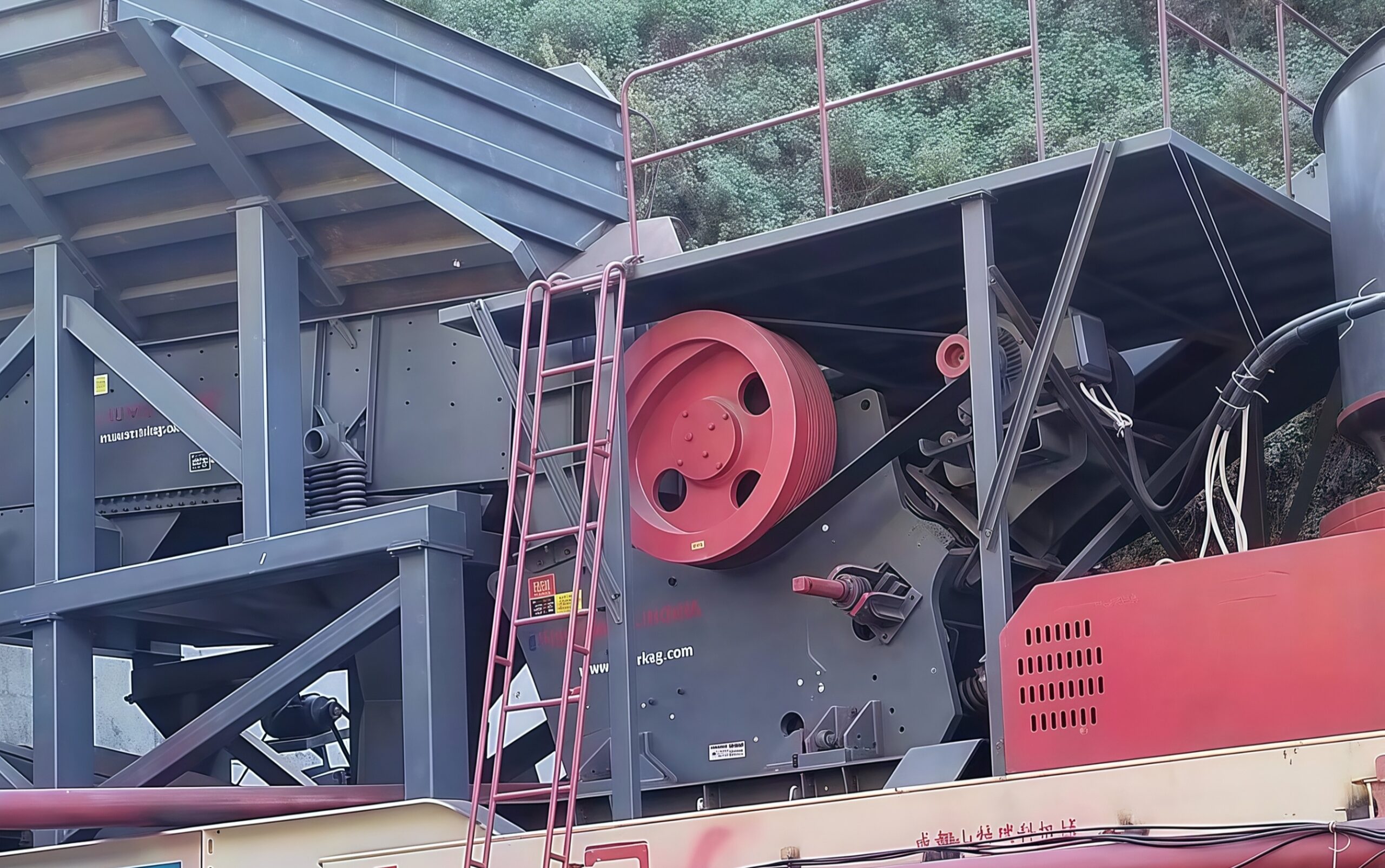

PEV Jaw Crusher Cases

Sandreck is a well-known Chinese integrated supplier of crushed stone equipment and solutions, and has provided services for over a thousand sand and gravel processing plants.

Processing material: Silica

Capacity: 200-400t/h

Finished size: 0-30mm, 30-80mm, 80-150mm

Processing material: Granite

Capacity: 200-400 t/h

Finished size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

Technical Parameters

- PEV Jaw Crusher

| Model | PEV500*750 | PEV600*900 | PEV750*1060 | PEV950*1250 | PEV1200*1600 | PEV1500*2000 | |

| Maximum Feed Size mm | 400 | 480 | 630 | 760 | 960 | 1200 | |

| Motor Power kw | 55-75 | 75-90 | 110 | 160 | 250 | 400 | |

| Product Size mm | Tight Edge Discharge Port mm | Processing Power t/h | |||||

| 0-60 | 40 | 60-85 | |||||

| 0-75 | 50 | 75-105 | |||||

| 0-90 | 60 | 90-125 | 120-155 | ||||

| 0-105 | 70 | 105-155 | 145-180 | 175-215 | |||

| 0-120 | 80 | 130-180 | 160-215 | 190-245 | |||

| 0-135 | 90 | 155-210 | 180-250 | 200-270 | |||

| 0-150 | 100 | 170-230 | 210-285 | 230-315 | 320-430 | ||

| 0-185 | 125 | 190-260 | 280-380 | 305-415 | 410-550 | ||

| 0-225 | 150 | 300-415 | 360-485 | 390-525 | 500-680 | 600-810 | |

| 0-260 | 175 | 420-595 | 470-640 | 565-820 | 720-975 | 920-1240 | |

| 0-300 | 200 | 535-760 | 635-965 | 810-1150 | 1025-1465 | ||

| 0-340 | 225 | 710-1115 | 900-1330 | 1130-1700 | |||

| 0-375 | 250 | 780-1270 | 990-1520 | 1250-1900 | |||

| 0-410 | 275 | 1080-1710 | 1365-2200 | ||||

| 0-450 | 300 | 1175-1910 | 1470-2465 | ||||

Testimonials

Sandreck PEV Jaw Crusher is suitable for ore (gold ore, tin ore, etc.); rock (limestone, marble, etc.); construction waste, etc.

When using Sandreck PEV Jaw Crusher, you need to check the lubrication system before starting, and control the feed amount and particle size.

Sandreck PEV Jaw Crusher inclues jaw plate, frame, eccentric shaft; shaft plate, spring, pulley, adjustment device and other auxiliary components.

Sandreck PEV Jaw Crusher is a Chinese manufacturer, each unit is ex-factory price, you can leave a message via WhatsApp(+8613666293477), we will contact you ASAP.

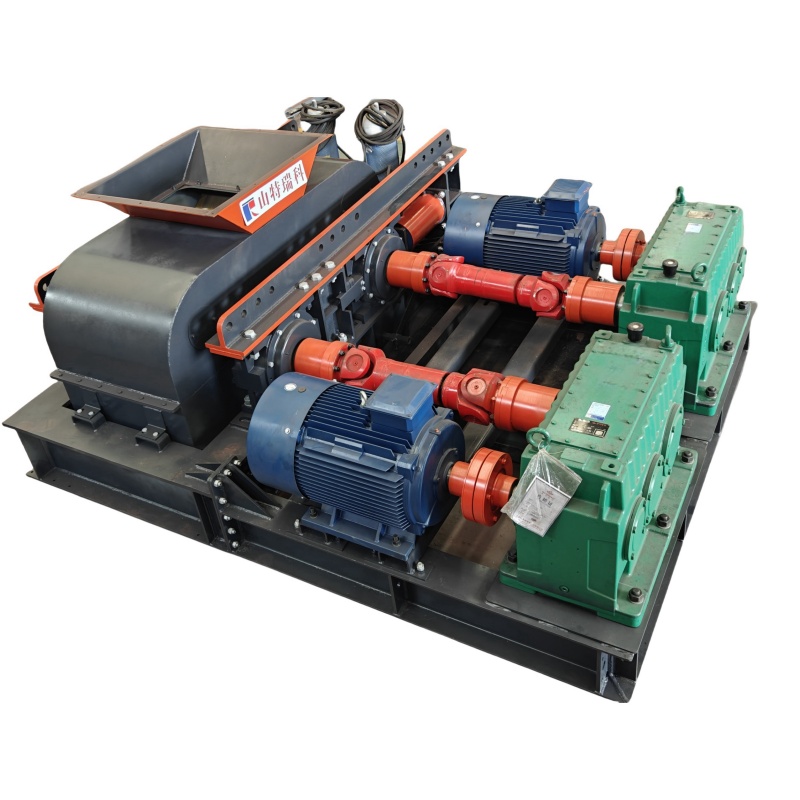

Related Product

Used for grading and screening of minerals, quarries, building materials, etc.

Crushing, sand making and shaping can be done by one machine.

Sandreck Double Roller Crusher is suitable for fine crushing of stones with a finished particle size of 0-5mm.

The crushing ratio is large and the feed particle size can reach 100mm.

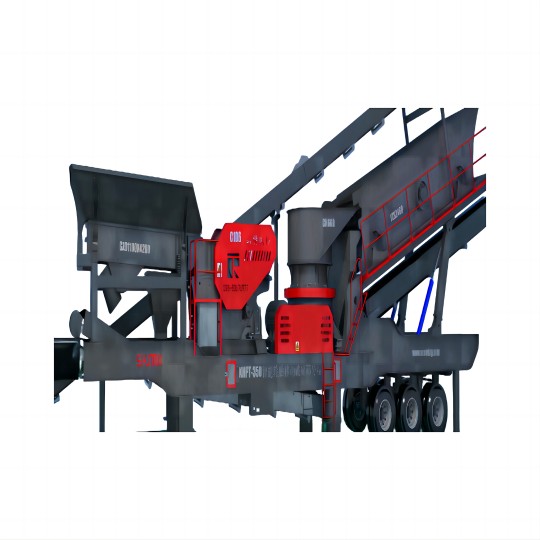

Mobile Crusher Plant’s locomotive traction can be transferred, which is flexible, suitable for multi-site cycle operation.