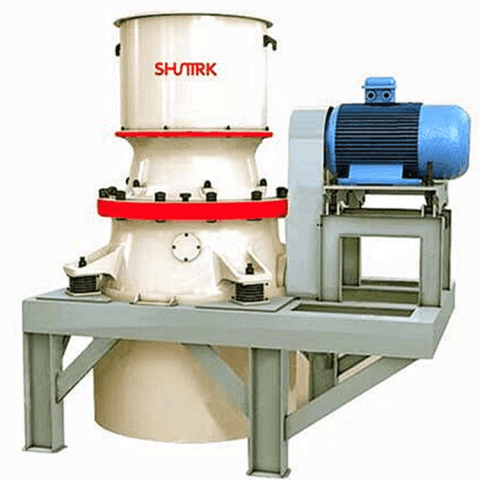

HST Cone Crusher

Sandreck HST Cone Crusher is used to crush all kinds of ores and rocks with medium hardness and above. It has the characteristics of light weight, small size, good grain shape and high degree of automation.

- Feed size: ≤300MM

- Motor power: 90-710KW

- Processing capacity: 60-700 T/H

Your Expert HST Cone Crusher Supplier in China.

Sandreck has been deeply involved in the cone crushing field for 20 years, and has widely absorbed advanced technologies from home and abroad. It integrates mechanical, hydraulic, electrical, automation and intelligent control technologies, and is particularly suitable for your medium, fine and ultra-fine crushing operations.

HST Cone Crusher is particularly suitable for crushing hard and medium-hard ores and rocks such as iron ore, copper ore, limestone, granite, basalt, river pebbles, construction waste, etc.

HST Cone Crusher Advantages

Sandreck HST Cone Crusher is equipped with a complete automatic control system, which can continuously monitor the operating status

Sandreck HST Cone Crusher’s discharge port can be adjusted by button control, which means it become more convinent to operate.

Sandreck HST Cone Crusher has a variety of standard crushing chambers, which can fully meet the requirements of variety particle form.

Inspection and maintenance only require the removal of the upper frame, which makes maintenance and inspection easier and saves maintenance costs.

Sandreck HST Cone Crusher is widely used in the production and processing of mining, building materials, metallurgy and other industries.

Sandreck HST Cone Crusher adopts PLC control system to realize dynamic gap adjustment and reduce downtime, also lessen the cost of labor.

Why Choose Sandreck HST Cone Crusher?

Sandreck is a HST Cone Crusher manufacturer, which provides original parts and worry-free operation and Sandreck HST Cone Crusher has a double safety controlled hydraulic and lubrication system, which can ensure that the equipment has overload protection function, and the bearing lubrication effect is good, which prolongs the life of the machine.

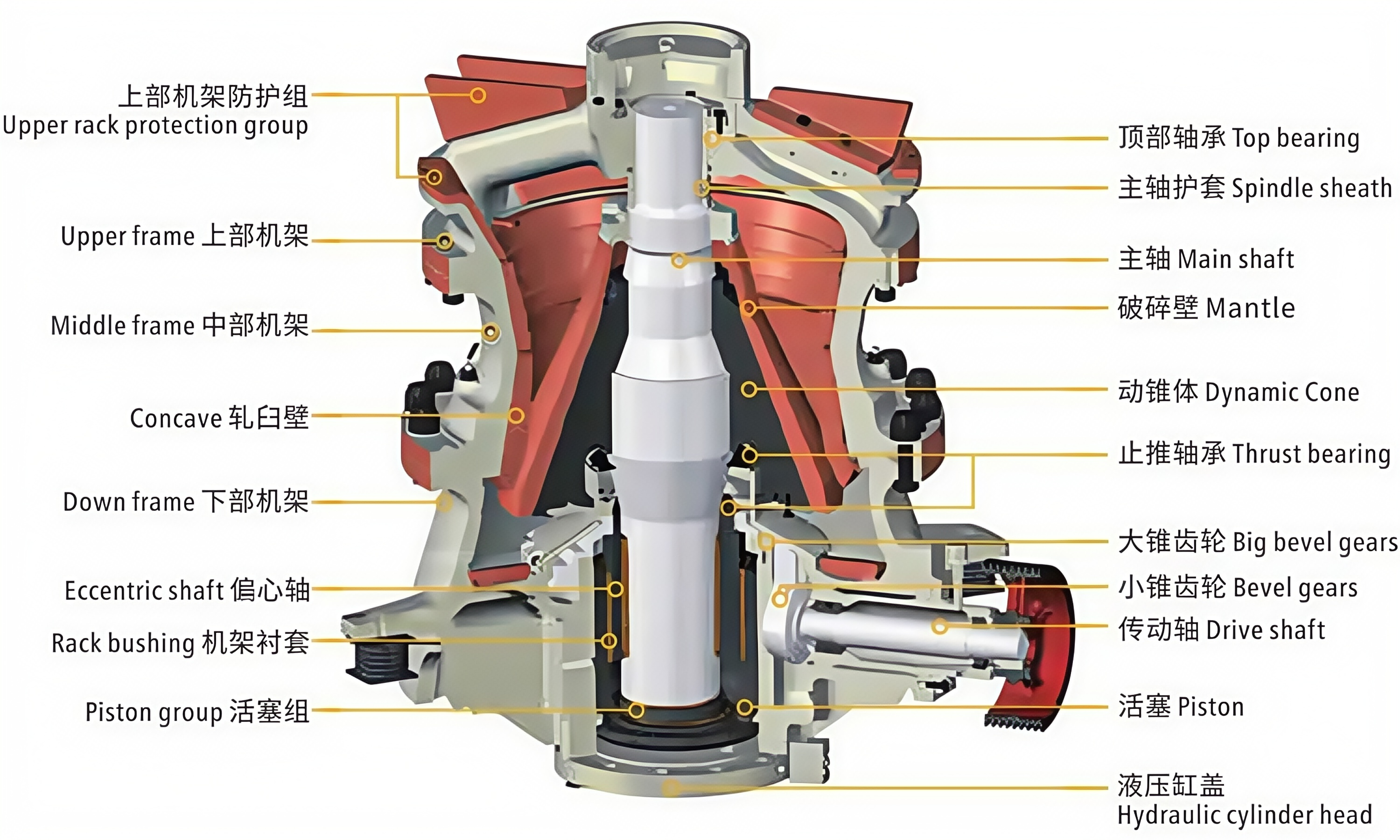

Sandreck HST Cone Crusher Main Components

The main components of the Sandreck HST Cone Crusher consist of the main parts such as the frame body, adjusting device, adjusting sleeve, crushing cone, transmission and eccentric sleeve, etc. These parts work together to enable the HST Cone Crusher to efficiently complete material crushing tasks.

Company Advantage

Sandreck is a HST Cone Crusher Manufacturing Company integrating R&D and design, production and sales. It possesses over 100 sets of machining equipment of various specifications, including CNC vertical lathes, deep hole drills, laser cutting machines, planers, CNC lathes, CNC boring and milling machines, etc.

We are a HST Cone Crusher corporation. Our crushing equipments are used by customers all over the world because we will tailor professional solutions and mature supporting design plans for you based on your needs, creating the greatest value for you.

Golden Service

For your HST Cone Crusher, we stand by your side 24 hours a day, providing round-the-clock protection for your choices!

We will arrange engineers to conduct actual surveys and scheme designs at your construction site, and provide customized product services according to your needs.

Our production process is clear and transparent, strictly controlled by professional quality inspection, with accurate inventory preparation and timely delivery.

We will dispatch engineers go to the site to provide technical training on equipment installation and commissioning, operation, maintenance and other aspects.

24-hour customer service response mechanism, providing you with technical services throughout the entire life cycle.

HST Cone Crusher Cases

Sandreck is a well-known Chinese integrated supplier of crushed stone equipment and solutions, and has provided services for over a thousand sand and gravel processing plants.

Processing material: Limestone

Capacity: 300 t/h

Finished size: <31.5mm

Processing material: Pebble

Capacity: 400 t/h

Finished size: <31.5mm

Technical Parameters

- HST Cone Crusher

| Model | Cavity Type | Feeding Size (mm) | Minimum Discharge Opening size(mm) | Processing Power(t/h) | Standard Installed Power(kw) | Maximum Installed power(kw) | Dimensions(mm) |

| HST100 | S1(Super thick) | 240 | 22 | 85-170 | 90 | 90 | 1550*1575*2545 |

| S2(Medium) | 200 | 19 | 70-130 | ||||

| H1(thin) | 135 | 10 | 45-130 | 1550*1575*1965 | |||

| H2(Medium) | 65 | 8 | 35-80 | ||||

| H3(Ultra fine) | 35 | 4 | 27-60 | ||||

| HST160 | S1(Super thick) | 360 | 25 | 120-345 | 132 | 160 | 1875*1920*3195 |

| S2(Medium) | 300 | 22 | 105-305 | ||||

| S3(thick) | 235 | 19 | 90-275 | ||||

| H1(thin) | 185 | 13 | 60-210 | 1875*1920*2400 | |||

| H2(Medium) | 90 | 10 | 65-165 | ||||

| H3(Ultra fine) | 50 | 6 | 48-105 | ||||

| HST250 | S1(Super thick) | 450 | 35 | 255-605 | 220 | 250 | 2100*2320*4096 |

| S2(Medium) | 400 | 29 | 215-515 | ||||

| S3(thick) | 300 | 25 | 190-490 | ||||

| H1(thin) | 215 | 16 | 110-395 | 2100*2320*2780 | |||

| H2 (Medium) | 110 | 13 | 115-340 | ||||

| H3(Ultra fine) | 70 | 8 | 90-225 | ||||

| HST315 | S1(Super thick) | 560 | 41 | 355-1050 | 315 | 315 | 2380*2735*4630 |

| S2(Medium) | 500 | 38 | 305-895 | ||||

| H1(thin) | 275 | 16 | 170-665 | 2380*2735*3265 | |||

| H2 (Medium) | 135 | 16 | 190-505 | ||||

| H3(Ultra fine) | 65 | 13 | 205-320 | ||||

| HST500 | S1(Super thick) | 560 | 54 | 575-1505 | 500 | 500 | 3216*3978*4892 |

| S2(Medium) | 500 | 54 | 550-1435 | ||||

| HST560 | H1(thin) | 300 | 22 | 430-1515 | 560 | 630 | 3780*2341*4531 |

| H2 (Medium) | 155 | 19 | 380-1375 | ||||

| H3(Ultra fine) | 80 | 10 | 270-775 | ||||

| HST750 | H1(thin) | 370 | 25 | 460-2130 | 710 | 750 | 3100*3623*5305 |

| H2 (Medium) | 195 | 22 | 525-1605 | ||||

| H3(Ultra fine) | 85 | 10 | 350-885 |

Testimonials

Sandreck HST Cone Crusher is suitable for various hard metal ores, limestone, granite, basalt, river pebbles, construction waste, etc.

Regularly check the lubrication system and wear of wearing parts to ensure sufficient oil and replace worn parts in time.

Sandreck HST Cone Crusher includes moving cone, fixed cone, main shaft, eccentric sleeve, hydraulic cylinder, hydraulic system and transmission device.

We are the source manufacturer of crushers in China, and each unit is ex-factory price. You can leave a message via WhatsApp (+8613666293477), and we will contact you as soon as possible.

Related Product

Sandreck Double Roller Crusher is suitable for fine crushing of stones with a finished particle size of 0-5mm.

Used for grading and screening of minerals, quarries, building materials, etc.