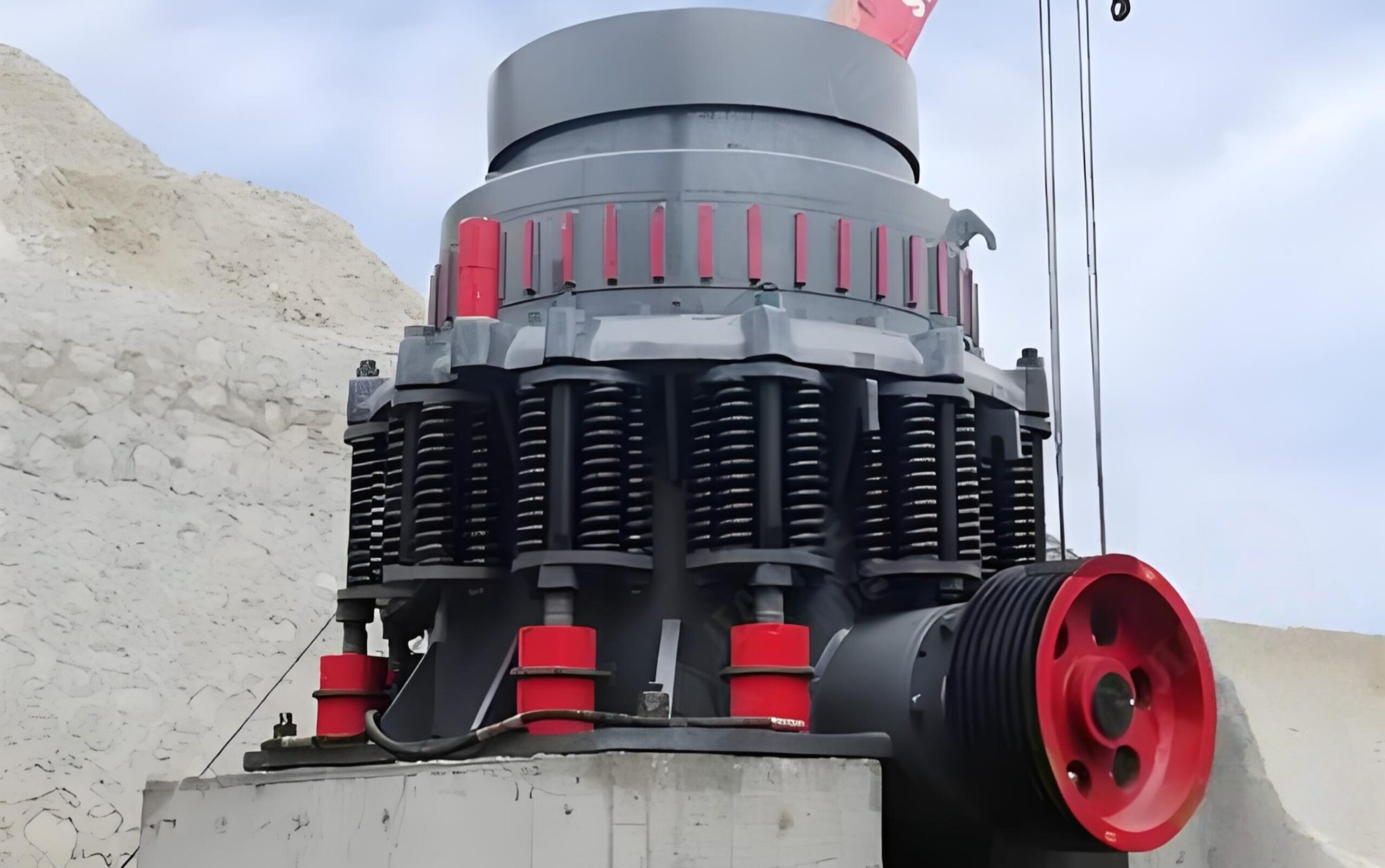

CS Cone Crusher

CS Cone Crushers are used for crushing medium-hard and harder ores and rocks.

- Feed size: ≤300MM

- Motor power: 90-440 KW

- Processing capacity: 60-700 T/H

Your Expert CS Cone Crusher Supplier In China

SandreckCS Cone Crusher is manufactured based on the principle of lamination crushing, with more crushing and less grinding, integrating optimized cavity type, reasonable stroke and advanced technology.

The CS Cone Crusher we sell has been verified by more than 10,000 users worldwide and has maintained an online operation rate of 98.6% for 7 consecutive years. They are particularly suitable for core crushing operations in mining, building materials, metallurgy and other fields.

Whether it is hard materials such as granite, basalt, marble, or medium and low hardness raw materials such as coal gangue and shale, a stable output of 80-2200 t/h can be achieved.

CS Spring Cone Crusher Advantages

Hydraulic overload protection device, thin oil lubrication station equipped with cooling system.

The crushing chamber of standard head and short head can be replaced by different components.

Heavy-duty design, optimized high-quality components and wear parts can reduce operating costs.

Can adapt to different operating environments to ensure the reliability of equipment.

All models of CS Spring Cone Crusher are equipped with multiple chamber types, suitable for various materials.

Adopting the lamination crushing principle, high-quality finished products are produced.

Why Choose Sandreck CS Cone Crusher

1.We optimize the cavity design and accurately match the speed and stroke to make our CS Cone Crusher achieve higher working efficiency and the processing capacity is more than 30% higher than that of similar one.

2.Equipped with self-developed wear-resistant composite liner, the service life of key components is extended by 3 times, which can reduce your crushing cost by 45%.

3.Adopts a large-diameter main shaft+heavy-duty main frame structure, with an intelligent thin oil lubrication system and overload protection device to reduce downtime and improve work efficiency.

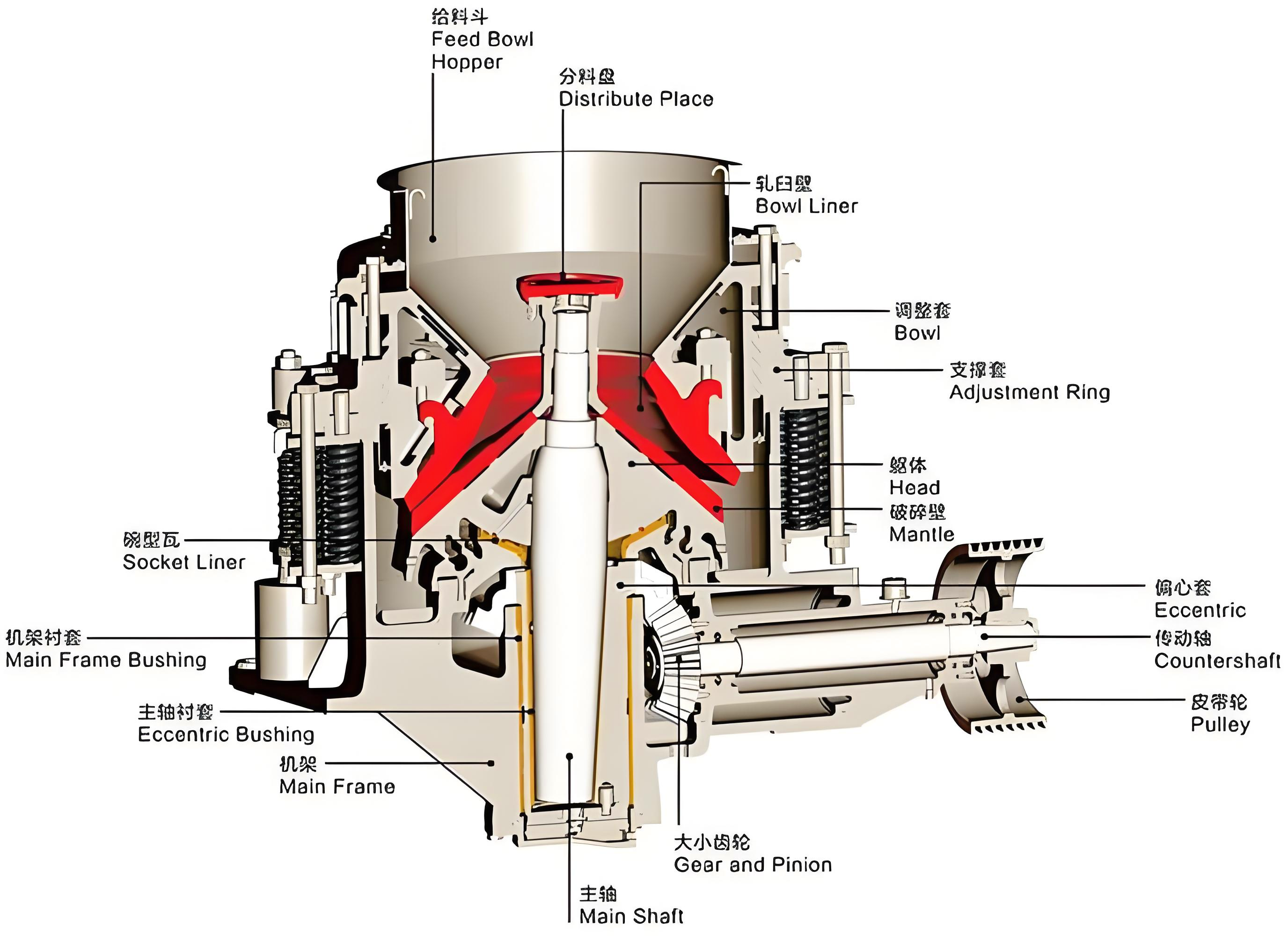

Sandreck CS Cone Crusher Main Components

The Sandreck CS Cone Crusher consists of a brace, belt hopper, dividing disc, rolling mortar wall, the body, crushing wall, the spindle, spindle sleeve and axis of rotation, which work together to enable the CS Cone Crusher to efficiently complete the material crushing task.

Company Advantage

Sandreck is a CS Cone Crusher Manufacturing Company integrating R&D and design, production and sales. It possesses over 100 sets of machining equipment of various specifications, including CNC vertical lathes, deep hole drills, laser cutting machines, planers, CNC lathes, CNC boring and milling machines, etc.

We are a CS Cone Crusher corporation. Our crushing equipments are used by customers all over the world because we will tailor professional solutions and mature supporting design plans for you based on your needs, creating the greatest value for you.

Golden Service

For your CS Cone Crusher, we stand by your side 24 hours a day, providing round-the-clock protection for your choices!

We will arrange engineers to conduct actual surveys and scheme designs at your construction site, and provide customized product services according to your needs.

Our production process is clear and transparent, strictly controlled by professional quality inspection, with accurate inventory preparation and timely delivery.

We will dispatch engineers go to the site to provide technical training on equipment installation and commissioning, operation, maintenance and other aspects.

24-hour customer service response mechanism, providing you with technical services throughout the entire life cycle.

CS Cone Crusher Cases

Sandreck is a well-known Chinese integrated supplier of crushed stone equipment and solutions, and has provided services for over a thousand sand and gravel processing plants.

Processing material: Cobblestone

Capacity: 300 t/h

Finished size: <50mm

Processing material: Quartz

Capacity: 200-400 t/h

Finished size: <31.5mm

Technical Parameters

- CS Cone Crusher

| Model | Moving Cone Diameter mm/feet | Cavity Type | Feed Port Size mm | Discharge Port Adjustment Range mm | Processing Power t/h | Drive Shaft Speed r/min | Power kw | Dimensions mm | |

| Closed Edge | Open Edge | ||||||||

| CS75B | 900(3’) | Thick Type | 159 | 175 | 13-38 | 59-163 | 580 | 75 | 2821*1880*2164 |

| Slim | 83 | 102 | 9-22 | 45-91 | |||||

| CS75D | 914(3’) | Thick Type | 51 | 76 | 6-19 | 65-140 | 580 | 75 | 2821*1880*2410 |

| Medium | 33 | 60 | 3-16 | 27-100 | |||||

| Slim | 13 | 41 | 3-13 | 27-90 | |||||

| CS160B | 1295(41/4’) | Thick Type | 316 | 241 | 19-51 | 172-349 | 485 | 185 | 2800*2342*2668 |

| Medium | 188 | 210 | 16-31 | 132-253 | |||||

| Slim | 109 | 137 | 13-31 | 109-181 | |||||

| CS160D | 1295(41/4’) | Thick Type | 70 | 105 | 10-25 | 109-227 | 485 | 160 | 2800*2342*2668 |

| Medium | 54 | 89 | 6-16 | 82-163 | |||||

| Slim | 29 | 64 | 3-16 | 36-163 | |||||

| CS240B | 1650(51/2’) | Thick Type | 241 | 268 | 25-64 | 299-635 | 485 | 240 | 3911*2870*3711 |

| Medium | 213 | 241 | 22-51 | 258-417 | |||||

| Slim | 188 | 209 | 16-38 | 181-327 | |||||

| CS240D | 1650(51/2’) | Thick Type | 98 | 133 | 10-25 | 190-336 | 485 | 240 | 3917*2870*3771 |

| Medium | 54 | 89 | 6-19 | 136-281 | |||||

| Slim | 35 | 70 | 5-13 | 90-209 | |||||

| CS400B | 2134(7’)

| Thick Type | 334 | 369 | 31-64 | 870-1400 | 435 | 400 | 5200*4300*4700 |

| Medium | 303 | 334 | 25-51 | 608-998 | |||||

| Slim | 253 | 278 | 19-38 | 381-726 | |||||

| CS400D | 2134(7’) | Thick Type | 127 | 178 | 13-25 | 454-599 | 435 | 400 | 5200*4300*4700 |

| Medium | 95 | 133 | 10-19 | 354-508 | |||||

| Slim | 51 | 105 | 5-16 | 190-408 | |||||

Testimonials

First, ensure that the feed particle size is uniform and meets the requirements, avoid overloading or foreign matter entering, and regularly check the moving cone, fixed cone and other wearing parts and replace them in time.

The main components of CS Cone Crusher include moving cone, fixed cone, eccentric sleeve, horizontal shaft, spring system and transmission device.

We are a Chinese crusher factory, each unit is ex-factory price, you can leave a message via WhatsApp (+8613666293477), we will contact you as soon as possible.

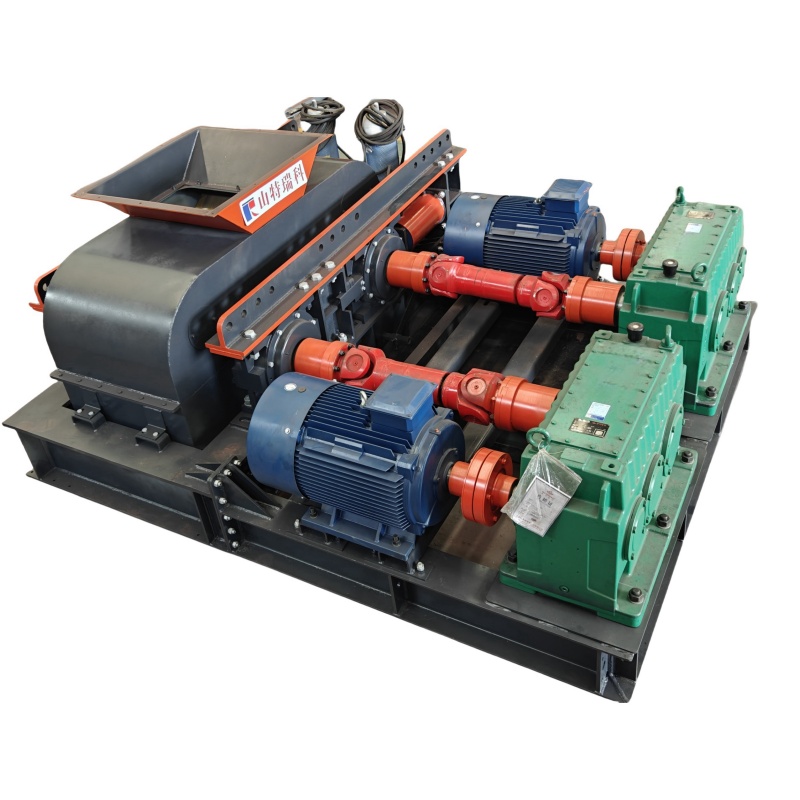

Related Product

The crushing ratio is large and the feed particle size can reach 100mm.

Sandreck Double Roller Crusher is suitable for fine crushing of stones with a finished particle size of 0-5mm.

Transfers materials between processes, connecting crushing, screening, washing, etc.

Linear feeding equipment that continuously feeds materials into the crusher.