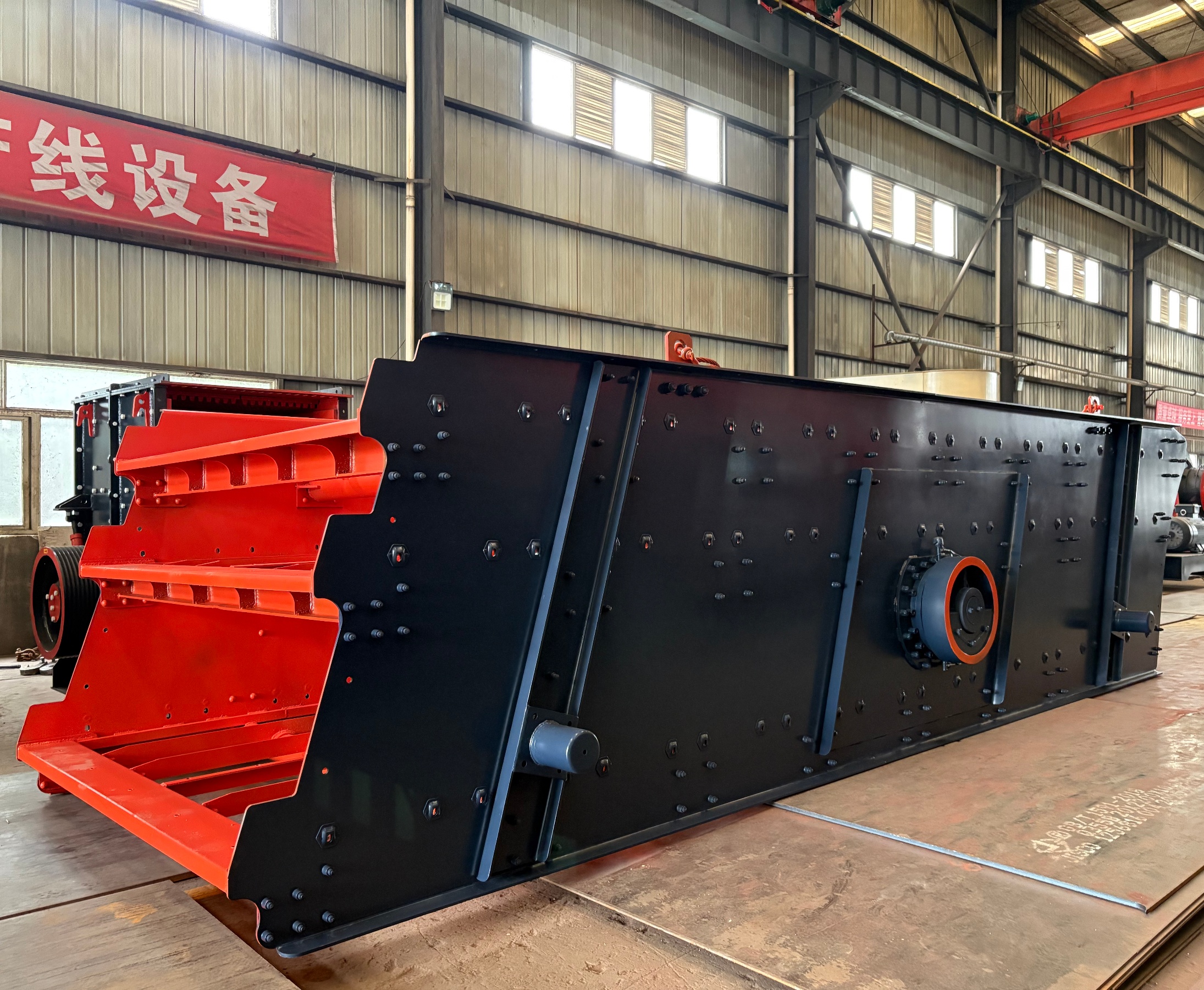

Vibrating Screen

The Sandreck Vibrating Screen is a heavy-duty mining screen suitable for demanding applications such as mining, mineral and aggregate processing. Its efficient vibrating motion can be used to stratify materials and classify them according to particle size.

![]() Feed size: 5-350mm

Feed size: 5-350mm

![]() Processing capacity: 50-700 t/h

Processing capacity: 50-700 t/h

![]() Motor power: 5.5-50kw

Motor power: 5.5-50kw

Your Expert Vibrating Screen Manufacturer In China

As a professional manufacturer of vibrating screens in China, Sandreck’s vibrating screens are the indispensable grading machines in such sectors as the aggregate, coal, mining, chemical and renewable energy industries. They are used extensively in mineral processing, sand and gravel production, construction waste disposal and solid waste treatment.

Our vibrating screens for mining are available to cover the requirements of heavy, medium and fine screening, making them suitable for the screening of primary and secondary materials and the grading of finished products.

The core of our vibrating screens consists of the screen box, screen cloth, motor/exciter, support springs and inlet and outlet ports, whilst the efficient circular vibration produced ensures precise screening.

Furthermore, our vibrating screens for mining can be fitted with spraying pipes making them suitable for flexible wet screening, which allows the various processing needs of different materials to be met.

Sandreck Vibrating Screen Advantages

Sandreck Vibrating Screen accelerates material screening and stratification, shortens the screening time.

All connections are connected by high-strength steel bolts to avoid welding stress and have a long service life.

Eccentric design,small screens use self-lubricating oil, large models employ thin-oil circulation.

Its screen design can output multiple particle size grades at the same time to meet the various needs.

Can quickly adapt to the screening of the material by changing the screen or adjusting the amplitude.

As a direct supplier of large-scale mining projects, Sandreck sells Vibrating Screen at factory prices, which are low.

Screen Media Options

Sandreck Vibrating Screens offer two specialized screen media options to meet various challenges:

• High-manganese steel screen: resistant to wear and impact, ideal for rock and high-impact screening.

• Polyurethane screen: moisture-resistant, anti-sticking, and noise-reducing, ideal for mineral processing and coal washing.

Modular Multi-Layer Design

Our Vibrating Screens feature a modular design with 1, 2, 3, or 4 deck options. They can simultaneously output multiple particle size grades to meet the requirements of the aggregate and mining industries.

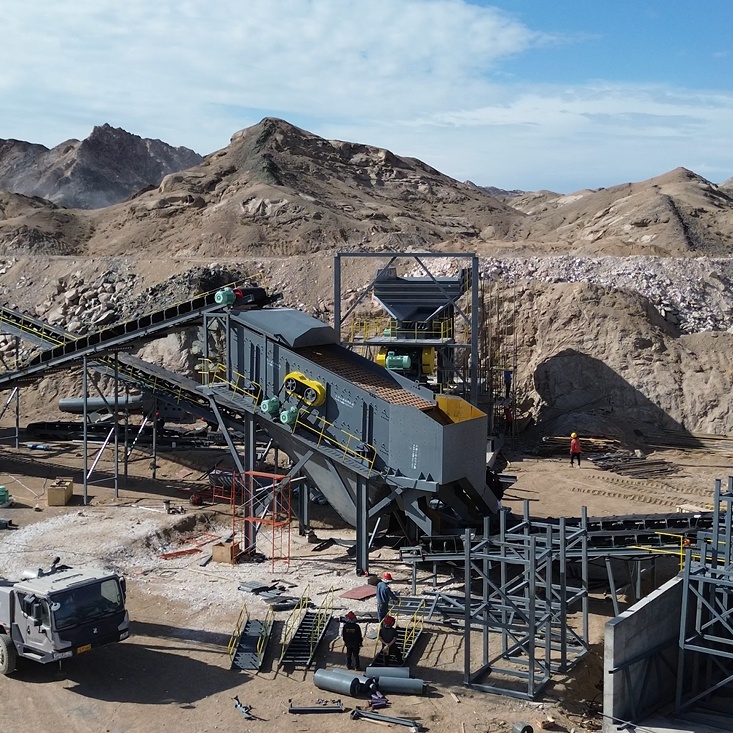

Sandreck Tailored Mining Vibrating Screen Solutions

We know that demanding mining sites need truly tailored Screening solutions. Sandreck specializes in offering deeply customized Vibrating Screen Equipment that is professionally configured to meet each individual challenge.

Based on the character of the ore you are processing, we closely match the feeding parameters and wear-resistant meshes of the Vibrating Screen with your needs for increased screening efficiency and lifetime.

To deal with high impact, high dust and other severe conditions, we mechanically overhaul the Vibrating Screen and use dust-proof and weather resistant designs for stable and continuous work.

Having considered your particular needs in screening at the various stages such as crushing and grinding, we help select the most suitable model of the Vibrating Screen and functional configuration required for your plant.

Based on your production requirements we flexibly adapt the size of the screen box and the combinations of 1-4 decks that would best help you gain improved classification and increased throughput.

Vibrating Screen Application Case

Technical Parameters

- Vibrating Screen

| Model | Number Of Layers | Motor Power (kw) | Output (t/h) |

| YZS1548 | 2-4 | 15-30 | 70-150 |

| YZS1860 | 2-4 | 22-37 | 80-200 |

| YZS2170 | 2-4 | 30-37 | 130-280 |

| YZS2772 | 2-4 | 30-45 | 160-400 |

| YZS3075 | 2-4 | (22-37)*2 | 220-500 |

| YZS3284 | 2-4 | (30-45)*2 | 300-500 |

Testimonials

Related Products

Mobile Cone Crusher’s important equipment for fine crushing in stone.

Linear feeding equipment that continuously feeds materials into the crusher.

Transfers materials between processes, connecting crushing, screening, washing, etc.

Classification equipment that separates solid particles by size or density.