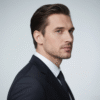

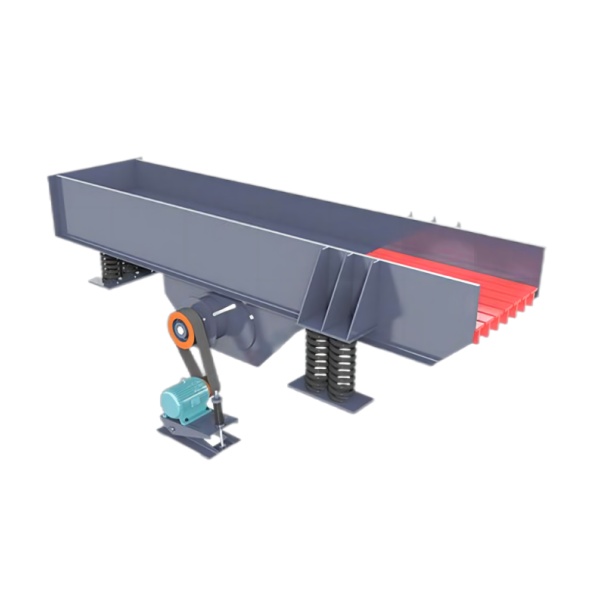

Vibrating Feeder

The Sandreck Vibrating Feeders, being a key auxiliary equipment in a crushing line, consistently and quantitatively feed lump, granular, and powdered products from the storage silo to the crusher or other downstream processes.

Feed size: ≤500mm

Motor power: 3.7-45kw

Output: 50-600t/h

Sandreck: brating Feeder Manufacturer In China

Sandreck, a professional Chinese Vibrating Feeders Manufacturer, provides efficient and reliable vibrating feeding equipment and system solutions required by various industrial departments.

The Vibrating Feeder is driven by an electric motor, so motor selection is important. Sandreck provides customized motors that comply with international specifications. Under different working conditions, we have a variety of motor to choose from, such as standard three-phase asynchronous motors, explosion-proof motors and frequency conversion speed regulating motors, in order to meet your operating needs.

By accurately controlling the vibration energy, the Vibrating Feeder achieves uniform and continuous transportation of materials. sandreck In order to adjust the vibration frequency and amplitude accurately, double eccentric shaft vibration exciter is adopted, which solves the problems of material blockage and low efficiency. Greatly guarantees the highly efficient and smooth working process of the conveying process.

Product By Features

It has a large amplitude, strong conveying capacity, and simple structure; it is well adapted for materials with bulky size.

It combines the feeding and classification functions; and it Woks well with bulky raw ores with high mud contents.

It has strong vibration performance, its robust trough can withstand a strong impact from falling materials.

This is used in the large-scale beneficiation plants, for short-distance transportation of materials with large grain size and weight.

It is a feeder with a simple structure and is applied to non-cohesive materials.

It has suspension installation or installation in flat forms, so that the unit work well in various complex working conditions.

Vibrating Feeder Advantages

Adopt frequency conversion drive technology, can save more than 20% energy consumption, processing capacity increased by 15%.

Slot body and liner plate are made of high chrome alloy or ceramic composite material, which can increase the anti-wear performance by 30%.

Through the touch screen or remote control module, you can adjust the amplitude, frequency and feeding volume in real time to accurately match the demand.

Fully sealed + wear-resistant coating, chemical industry, metallurgy and other harsh scenes make the operation of this machine stably.

As a direct supplier and source factory of large-scale mining projects, Sandreck’s Vibrating Feeders are sold at factory price.

Shaker, spring and other key components can be quickly disassembled and assembled, daily maintenance only requires lubrication and bolt inspection.

Precise Feeding, Uniform Conveying

Engineered for reliability, the Sandreck Vibrating Feeder uniformly transports ores in crushing lines and precisely doses powders and granules in batching operations. It is built to handle even damp, sticky, and mildly corrosive materials with ease.

Vibrating Feeder Application Areas

Sandreck Vibrating Feeder is mainly used for material conveying in mining, metallurgy, chemical industry and other industries.

- Mining Beneficiation

- Metallurgical Batching

- Chemical/Building Materials Production

Sandreck Vibrating Feeder: Direct from Our Factory

Why is our vibrating feeder so affordable? Because we are the factory. By manufacturing everything in-house and selling directly to you, we eliminate middleman markups. This allows us to offer you robust and high-performance equipment at a highly competitive price. Enjoy cost-effective solutions without compromising on quality or durability for your mining, metallurgy, and chemical operations.

Why Select Sandreck Vibrating Feeders?

Because we offer much more than equipment – we offer a value commitment that covers the whole life of the product

In-depth analysis of the materials, working conditions and processes allows Sandreck to recommend and customize the ideal Vibrating Feeder solution, which will be integrated into your production line without fuss.

Every Vibrating Feeder is produced according to standardized proceedings, updated and inspected at the relevant stages.

We make available expert installation advice, practical training and prompt response services. Lifelong technical advice and regular spare parts services ensure the continuing and consistent operation of your Vibrating Feeder during its total life.

Vibrating Feeder Cases

Testimonials

Sandreck is a Vibrating Feeder manufacturer, integrating manufacturing, production and supply in one. We have a professional after-sales team, there are original parts to provide, maintenance costs are very low.

Sandreck have a dedicated production team. The delivery time of our Vibrating Feeder is generally made within 20 days after the contract is signed.

You can send us a message on WhatsApp(+86 13666293477) or leave your contact details on our website, later our online customer service will contact you to give you the info of Sandreck Vibrating Feeder.

Related Products

Mobile Crusher Plant’s locomotive traction can be transferred, which is flexible, suitable for multi-site cycle operation.

This machine adopts self-driven design which is suitable for complex working conditions and frequent transfer projects.

Portable Crushing Plant can be driven by motor or diesel generator, which is portable and convenient for translation, easy for operation.