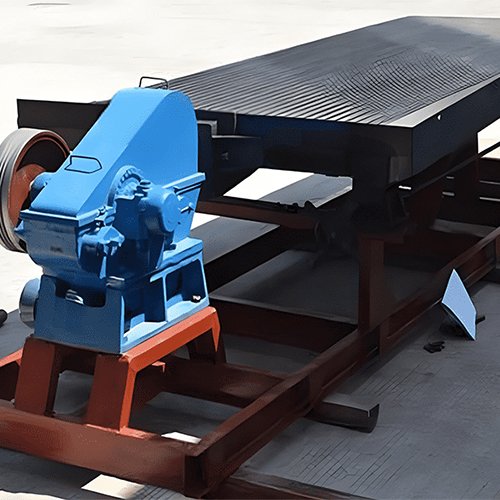

Shaking Table

Sandreck Shaking Table is widely used to separate various metal and non-metal materials, especially in gravity separation of fine-grained materials.

- Improving coal quality and efficiency

- Recovering pyrite from coal gangue

- Metal ore separation

What Is Shaking Table?

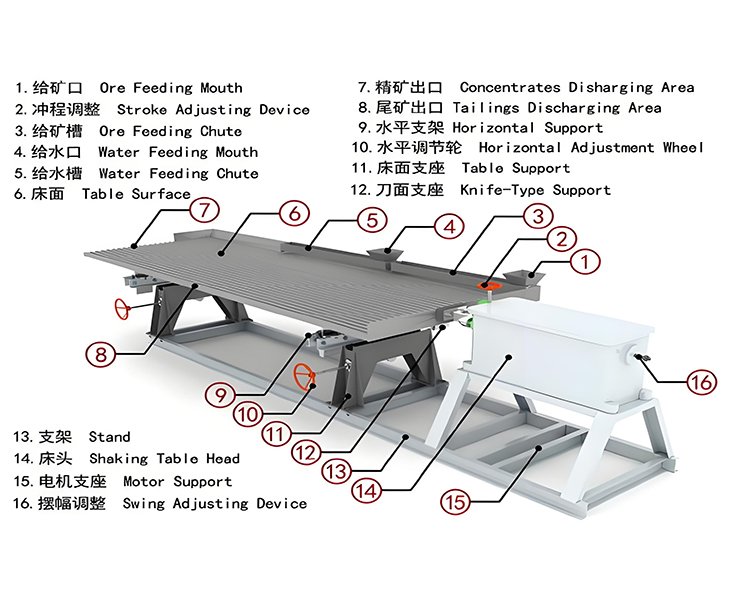

Are you looking for an energy-efficient mineral separation equipment? Sandreck Shaking Table is the product you need. It accurately separates mineral particles of different specific gravities through the synergy of asymmetric reciprocating motion and lateral water flow. Sandreck Shaking Table adopts a cam lever slider design. You only need to adjust the slider position to change the stroke length.

Sandreck Shaking Table Advantages

The enrichment ratio of the Shaking Table is as high as 100:1, which can produce the final concentrate and tailings at one time.

Adjustable stroke frequency can meet the needs of minerals of different particle sizes, increases the processing capacity by 40%.

No chemical agents are required throughout the process, energy consumption is reduced by 65% compared with traditional equipment.

The material recovery rate is increased to 98.5%, and the fluctuation value of the concentrate grade is controlled within ±0.3%.

The modular design shortens the maintenance time by 70%, and the life of key components is extended to 30,000 hours.

Source manufacturers and suppliers, factory-saleable equipment are all at the lowest factory price, low cost and high efficiency.

Why Choose JJF Flotation Equipment?

The frequency of Sandreck JJF Flotation Equipment strokes can be easily controlled through the motor pulley. The operation threshold is low and the flexibility is extremely high. Its processing capacity covers 0.1-1.8 tons/hour, which can meet the diverse needs of small and medium-sized ore dressing plants.

More About Our Company

- Technical Parameters

Mode | Coarse Sand Bed Surface | Fine Sand Bed Top | Notched Bed Surface |

| Bed Size(mm) | 4436X1825X1536 | ||

| Stroke(mm) | 16~22 | 10~16 | 10~16 |

| Jig(r/min) | 240~290 | 300~320 | 330~340 |

| Water Consumption(t/h) | 190 | 80 | 50 |

| Capacity(t/h) | 30 | 8 | 8 |

| Feed Size(mm) | 2~0.2 | 0.5~0.037 | 0.074~0.019 |

| Feed Concentration(%) | 20~25 | 15~20 | 15~20 |

| Minimum Mounting Grade(°) | 2°30″ | 1°50″ | 0°45″ |

| Overall Dimension(mm) | 5454X1825X1242 | ||

| Stroke Adjustable Range(mm) | 8~22 | ||

| Power(kw) | 1.5 | ||

Sandreck is a Shaking Table manufacturer, integrating manufacturing, production and supply in one. We have a professional after-sales team, there are original parts to provide, maintenance costs are very low.

Sandreck have a dedicated production team. The delivery time of our Shaking Table is generally made within 20 days after the contract is signed.

You can send us a message on WhatsApp(+86 +13666293477) or leave your contact details on our website, later our online customer service will contact you and offer the price of our Shaking Table.